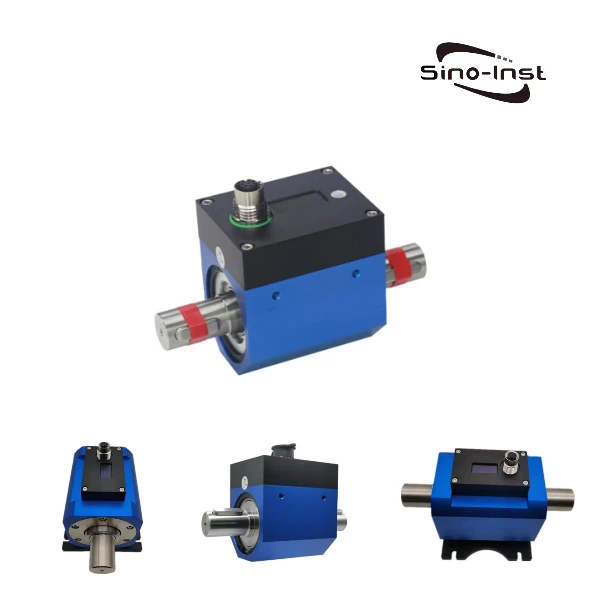

Non contact torque sensor is also called Rotary Shaft Digital Non-Contact Torque Sensor. The 5069 Non contact torque sensor is a high precision dynamic torque sensor. It can be output with speed, and can display torque/speed/power with OLED panel. Range: 5-5000Nm optional. It can meet most high-speed torque measurement occasions. It is an ideal product to replace other torque sensors.

Features of 5069 Non Contact Torque Sensor

- Contactless

- Range 5-5000Nm

- Output 10±5KHz, 4-20mA, ±5VDC, ±10VDC, RS485/232

- Stainless steel shaft

- Maximum speed 15000RPM

- With speed output

- Can display torque/speed/power with OLED panel

Technical Parameters

| Range: | 5-5000Nm |

| Torque output: | 10±5KHZ, 4-20mA,0±5/10VDC,0-5/10VDC, RS485 |

| Span temperature effect -%RO/℃: | ±0.02 |

| Compensation temperature range -°C: | -10 ~+60 |

| Operating temperature – °C: | -20~80℃ |

| Accuracy – %FS: | ±0.1,0.2 |

| Electrical connections: | 6-pin or 8-pin |

| powered by: | 12-30VDC |

| Zero temperature effect -%RO/℃: | ±0.02 |

| Span temperature effect -%RO/℃: | ±0.02 |

| Safe Overload – %RO: | 200 |

| Shaft Material: | Stainless steel |

| Shell material: | Aluminum |

Optional:

- Speed measurement;

- Speed-RPM…… 0,100,200-1000,2000,4000,6000,8000,10000,12000,15000;The speed varies with the range, please specify when ordering;

- With OLED display, it can display torque/speed/power at the same time;

- Standard cable length is 5 meters, please specify when ordering;

- Can be customized;

Accessories:

- Torque Meter

- Integrated meter torque/speed/power

- Computer display software

Dimensions

| Cap(Nm) | A | B | C | D | E | F | G | φH | h | I | J | K | L | M | key (b*h*|*n) |

| 5-100 | 185 | 111 | 3.5 | 7 | 30 | 73.5 | 70 | 18 | 14.5 | 36 | 1.5 | 80 | 22 | 4-M5 DP9 | 6*6*22*1 |

| 200-500 | 198 | 114 | 3 | 7 | 35 | 80 | 85 | 28 | 24 | 50 | 1.5 | 84 | 36 | 4-M5 DP11 | 8*7*30*1 |

| 1k-2k | 288 | 134 | 5 | 7 | 70 | 125 | 125 | 45 | 34 | 70 | 1.5 | 94 | 50 | 4-M8 DP15 | 14*9*60*2 |

| 3K-5K | 355 | 141 | 4 | 7 | 100 | 158.5 | 160 | 75 | 60 | 100 | 2.5 | 100 | 80 | 4-M10 DP18 | 20*12*93*2 |

Frequently asked questions

If you cannot find an answer to your question in our 5069 Non Contact Torque Sensor for Dynamic Torque Measurement, you can always contact us

and we will be with you shortly.

More Featured Torque Sensors For Sale

Sino-Inst is a manufacturer of Non Contact Torque Sensor for Dynamic Torque Measurement-5000Nm-OLED. We offer more than 20 types of Non Contact Torque Sensors. Non Contact Torque Sensors can measure a variety of different mechanical power, rotational speed and torque measuring devices.

Non Contact Torque Sensor is also called rotary torque sensor, torque transducer. Mainly used for torque measurement in dynamic situations. The Non Contact Torque Sensor is equipped with a speed measuring device, which can measure the rotational speed while measuring the torque. At this time, the Non Contact Torque Sensor can also be called a torque speed sensor.

Sino-Inst’s Non Contact Torque Sensor, made in China, have good quality, with better prices. Our Non Contact Torque Sensors are widely used in China, India, Pakistan, USA and other countries.

Sino-Inst’s entire team is well trained, so we can ensure that each customer’s needs are met. If you need any help with your product requirements, whether it is a Non Contact Torque Sensor, level sensors, or other equipment, please give us a call.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

Non Contact Torque Sensor for Dynamic Torque Measurement-5000Nm-OLED

Non contact torque sensor is also called Rotary Shaft Digital Non-Contact Torque Sensor. The 5069 Non contact torque sensor is a high precision dynamic torque sensor. It can be output with speed, and can display torque/speed/power with OLED panel. Range: 5-5000Nm optional. It can meet most high-speed torque measurement occasions. It is an ideal product to replace other torque sensors.

Product SKU: 5069 Non Contact Torque Sensor for Dynamic Torque Measurement

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 800

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5