Turbine Flow Meters for Liquid

Turbine flow meters are flow sensors work for the inline liquids.

Turbine flow meters are cost-effective and offer reliable,

measurement with minimal flow meter maintenance required.

Turbine flow meters measure the velocity of liquids, gases, and vapors in pipes,

such as hydrocarbons, chemicals, water, cryogenic liquids, air, and industrial gases.

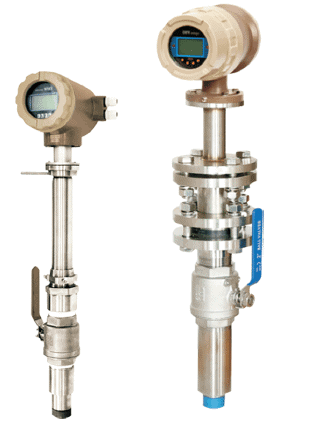

Featured Turbine Flow Meters

Gas Turbine Flow Meters

Liquid Turbine Flow Meters

Insertion Turbine Flow Meters

Sanitary flow meter

Turbine Flow Meter Working Principle

Turbine meters are simple to operate and maintain,

and in-service worldwide as a reliable, cost-effective method,

for achieving accurate flow measurement.

Turbine flow meters are designed to maximize throughput,

and minimize pressure drop, maintain high flow rates over an extended flow range,

and offer pulse output that is linear to the flow rate.

The turbine meters also minimize fiscal measurement uncertainty,

by delivering high-frequency pulse resolution,

to account for minute increments of the flow rate.

Turbine flow meters use the mechanical energy of the fluid to rotate a “pinwheel” (rotor) in the flow stream.

Blades on the rotor are angled to transform energy,

from the flow stream into rotational energy.

The rotor shaft spins on bearings.

When the fluid moves faster, the rotor spins proportionally faster.

Turbine flow meters now constitute 7% of the world market.

Shaft rotation can be sensed mechanically or by detecting the movement of the blades.

Blade movement is often detected magnetically,

with each blade or embedded piece of metal generating a pulse.

Turbine flowmeter sensors are typically located external to the flowing stream,

to avoid material of construction constraints that would result,

if wetted sensors were used.

When the fluid moves faster, more pulses are generated.

The transmitter processes the pulse signal to determine the flow of the fluid.

Transmitters and sensing systems are available to sense flow,

in both the forward and reverse flow directions.

You may like: Industrial flow meters

Turbine flow meter equation

The relationship between volumetric flow rate of the turbine flowmeter and the frequency of the pulses generated by the pickup sensor can be expressed in the form of the equation:

f = kQ

Where,

f = Frequency of pulses generated by pickup sensor(Hz, equivalent to pulses per second)

Q = Volumetric flow rate (e.g. litres/min)

k = “K” factor of the turbine meter (e.g. pulses per litre)

You may like Coriolis mass flow meter

Turbine flow meter advantages and disadvantages

Advantages of Turbine Flow Meters

- High precision, generally up to ± 1% R, ± 0.5% R.

- Output pulse frequency signal, suitable for total metering and connection with a computer, no zero drift, strong anti-interference ability.

- Compact and lightweight, easy installation and maintenance, and large-circulation capacity.

- Good repeatability, short-term repeatability of 0.05 ~ 0.2%, due to good repeatability, frequent calibration or online calibration can get very high precision.

- A special type of sensor can be designed according to user needs, such as low-temperature type, two-way, downhole type, mixed sand special type.

- Pressure compensation can be performed under the pressure state in which the gas to be measured is stable.

- The turndown is wide, medium and large caliber up to 1:20, small-caliber is 1:10.

Disadvantages of Turbine Flow Meters

- Need to be calibrated regularly, there is no way to maintain accuracy for a long time, can not work continuously for a long time.

- The cleaning requirements of the medium are high, but the filter can be installed.

- The flowmeter has a large influence on the flow velocity distribution (flow regulator can be installed).

- It is not suitable for places where the flow rate is drastically changing.

- Not suitable for testing of corrosive media.

You may like:Wastewater Flow Meter

Application Industries

- Oil & Gas

- Water injection

- Test and production separators

- Disposal wells

- Hydraulic fracturing

- Chemical injection

- Natural gas pipelines

- Aerospace/Defense

- Engine Testing

- Fuel flow measurement

- Shipboard reverse osmosis systems

- Monitor fuel supply to ship engines

- Pharma-Bio Tech, Food & Beverage

- Sanitary measurement

- Pill coating

- Power Generation

- Custody transfer

- Industrial & Municipal

- Building automation

- HVAC

- Water metering

- Cryogenics

- Liquids measurement for plant applications and truck deliveries

Turbine Flow Meters Price

Sino-Instrument offers all kinds of Turbine flow meters, made in China. Best Quality, and Best Price!

The price of Turbine Flow Meter is around USD400-700/pc,

which will be affected by:

- Fluid Type

- Viscosity

- Connection

- Pipe Sizing

- Process Temperature (min & max)

- Flow Range (min & max)

- Pressure Range (min & max)

- Accuracy Range

- Specific Application

All Flow Meters can work with the NEW AMS TREX, HERE!

Sino-Instrument, Manufacturer for turbine flow meters,

like: gas turbine flow meter,

liquid turbine flow meter, sanitary turbine flow meter,

insertion turbine flow meter, steam turbine flow meter,

and natural gas turbine flow meter.

Sino-Instrument’s turbine flow meters, made in China,

Having good Quality, With better price.

Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Request a Quote

Insertion Magnetic Flow Meter SI-3121 ULT-200 Ultrasonic Level Detector ULT-100A Ultrasonic Level Transducer SI-100 Magnetostrictive Level Sensor Orifice flow meter 804 Radar Level Sensor SI-151 Hydrostatic Level Sensor Venturi flowmeter 3051ANB Annubar Flow Meter Liquid Turbine Flow Meters

Gas Turbine Flow MetersIndustrial Vortex Flow Meter Emerson AMS Trex Device Communicator General Purpose Mag Meter Thermal mass flowmeters Orifice flow meter

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.