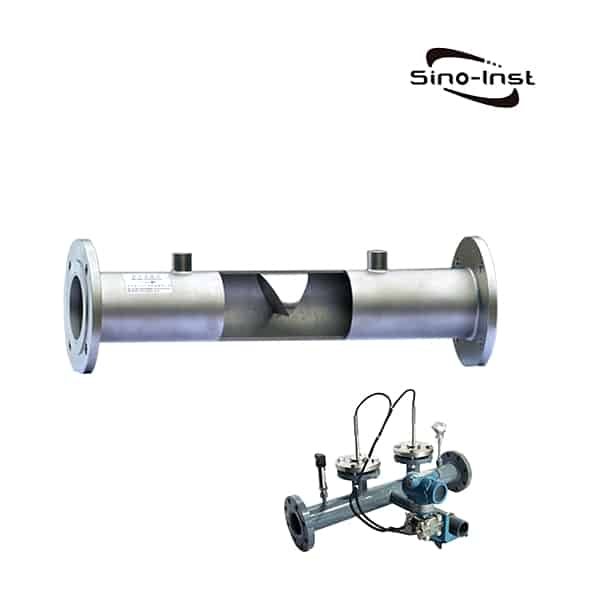

Wedge flow meter is a differential pressure flow meter. The detection part is a V-shaped wedge (also called a wedge-shaped throttle).

Wedge flowmeter is a new type of throttling differential pressure flow measuring instrument. The wedge flowmeter can perform high-precision flow measurement in fluids with high viscosity and low Reynolds number (Reynolds number 500 can be used). It has unparalleled advantages in flow measurement occasions with low flow rate, small flow and large pipe diameter. Except for general gas, liquid and steam, it is especially suitable for flow measurement of high-viscosity, dirty liquid and high-dust gas.

Sino-Inst, Manufacturer for differential pressure flow meters. Including the Orifice plate, Venturi, Annubar, etc. Suitable for liquid, gas, and steam flow measurement. Please contact our sales engineers for technical support!

Features of Wedge Flow Meter

High accuracy, good stability and good repeatability. Measurement error: ±0.5%F.S; long-term stability: ±0.1%F.S/Y.

Simple structure, high reliability and long service life. The unique structure of the wedge flow sensor, the configuration of the high-performance differential pressure transmitter, and the strict degree of testing, testing and standardization. The service life can reach more than 10 years.

Wide measuring range. The range ratio is generally 1:25, up to 1:33. When the differential pressure of the differential pressure transmitter is changed, it can reach more than 1:100

The scope of application is extremely wide. It is not only suitable for single-phase fluids, but also for two-phase fluids such as gas-liquid, gas-solid and liquid-solid. Its Reynolds number can be as small as 300 and as high as 1×107. The wedge flow meter can work in the state of measuring flow or in the state of turbulent flow, and its lowest flow rate is 0.01m/s. It is suitable for the flow measurement of various liquids, gases, steam and high dust-containing gases such as high temperature, high pressure, high viscosity, heavy corrosion, easy crystallization, suspended solids, long fibers, etc.

Anti-adhesion, no deposition, no clogging. The anti-adhesion structure design of the wedge-shaped sensor measuring tube and the throttling piece eliminates the adhesion and accumulation of sand, dust, suspended solids, and fibers in the measured medium to the flow sensor measuring tube. At the same time, the corrosion of the measuring tube is prevented, thus ensuring the long-term constant of the measuring tube diameter and the long-term standard of flow measurement.

Integration. Integrated installation of wedge sensor, three groups of valves and differential pressure transmitter. Eliminates the need for pressure guiding pipelines, valves, pipe fittings, and the entire system is simpler. The measurement accuracy and reliability are greatly improved.

Intelligent. When selecting the intelligent differential pressure transmitter, the process parameters can be set and configured through HART protocol or other communication methods. According to the change of the measured medium flow rate, the differential pressure is adjusted to greatly broaden the system range. When the intelligent multi-parameter differential pressure transmitter is selected, multi-parameter measurement (differential pressure, volume flow, mass flow, pressure, temperature) can be realized. Realize complete temperature and pressure compensation, and directly output accurate flow signals.

Low installation requirements for straight pipe sections. Low requirements for installing straight pipe sections can effectively avoid and reduce the additional measurement uncertainty of the measurement system.

The pressure loss is small, saving energy.

Read more about: Coriolis meter for High viscosity liquid

Specification of Wedge Flow Meter

| Accuracy | 0.5 grade, 0.2, 0.3, 0.4 grade precision negotiated order |

| Long-term stability | ±0.2%F.S/Y |

| Repeatability | ±0.2% |

| Suitable test medium | Various liquids, gases and steam |

| Minimum flow rate | 0.01m/s |

| Measuring range | Generally 1:25, up to 1:33, when the differential pressure of the differential pressure transmitter is changed. It can reach more than 1:100 |

| Pressure loss | Measure about 1/5 of the differential pressure (about 1/3 of the orifice plate) |

| Reynolds number application range | The lower limit is 500, the upper limit is less than or equal to 1×10 7 (when measuring under low Reynolds number, the range is relatively reduced, and the uncertainty of the outflow coefficient is relatively increased) |

| Measured liquid viscosity | 500mpa.s, or higher |

| Working pressure range | -0.1~42MPa |

| Range of working temperature | -160℃~450℃ (up to 700℃ for special) |

| Applicable pipe size | DN10mm~DN1200mm (special up to 2500mm) |

| Wedge ratio h/d | 0.2, 0.3, 0.4, 0.5 |

| Differential pressure/pressure transmitter power supply | 24VDC |

| Differential pressure/pressure transmitter output | 4~20mADC (HART protocol can be selected) |

Extended reading: Flat Pressure Sensor for High Viscosity Fluids

Wedge Flow Meter Applications

The wedge flow meter can successfully measure the following fluids;

- Gas: coal gas, natural gas (including high-humidity natural gas and unclean natural gas containing other impurities). Air (including air containing water, solid particles and other suspended matter).

- Steam: saturated steam, superheated steam.

- Liquid:

- Oils (such as crude oil, fuel oil, coal tar, residual oil, paraffin oil, water-containing emulsified oil, water-containing sandy slop oil, etc.).

- Slurry (such as oil slurry, iron ore slurry, paper slurry, mud, coal Pulp, etc.).

- Water (such as: purified water, sewage, industrial wastewater, river source water containing silt and debris, etc.).

- Various aqueous solutions (such as: various acid, alkali, salt solutions with strong corrosiveness and easy crystallization , Solutions containing more suspended solids, etc.).

- Special fluid.

Extended reading: [Working principle&Price]SI3051ANB Annubar Flow Meter

Wedge Flow Meter Working Principle

When the fluid flows into the flow tube, it is forced to accept the vertical movement of the flow tube. In the half cycle of the upward vibration of the flow tube, the fluid resists the upward movement of the tube and exerts a downward force on the flow tube.

On the contrary, the fluid of the wedge flow meter exerts an upward force on the flow tube to oppose the downward movement of the tube and reduce its vertical momentum. This causes the flow tube to twist. In the other half of the vibration cycle, the flow tube vibrates downwards and twists in the opposite direction.

It vibrates at its resonant frequency by driving the coil and the feedback circuit. The resonance frequency of the vibrating tube is related to the structure, material and quality of the vibrating tube. The quality of the vibrating tube consists of two parts: the mass of the vibrating tube itself and the quality of the medium in the vibrating tube.

After each sensor is produced, the quality of the vibrating tube itself is determined. The mass of the medium in the vibrating tube is the product of the density of the medium and the volume of the vibrating tube. The volume of the vibrating tube is fixed for each caliber sensor. Therefore, the vibration frequency is directly related to the density. For sensors that determine the structure and material, the density of the medium can be obtained by measuring the resonance frequency of the flow tube.

When using a wedge flow meter, if a small amount of gas flows in a stratified or wavy flow in the water pipe. The fault phenomenon is manifested as an increase in error, that is, the flow measurement value does not match the actual value.

If the flow is a bubble flow or a plug flow, the fault phenomenon is except that the measured value does not match the actual value. The output will fluctuate because the gas phase instantly covers the electrode surface.

If the cross-sectional area of the horizontal pipeline in the stratified flow increases in the gas phase. That is, the degree of liquid not full of the tube increases. There will also be output shaking, and the situation is more serious if the liquid is not full. If the liquid level is below the electrode, the output will be over-full.

Extended reading: V-Cone Flow Meter Applications

Wedge Flow Meter Calculation

Where qv—-volume flow meter, m³/s

C——Outflow coefficient;

ε—–Expansion coefficient;

m——throttling area ratio;

D——Inner diameter of pipe, m;

△p——Differential pressure, pa;

ρ——The density of the measured medium, kg/m³

The wedge flow meter has correction functions for parameters such as flow coefficient, non-linear error, temperature change, and density change. The measurement accuracy can reach 0.5%. Can have on-site display and standard current signal (4~20mA DC) output. It can be conveniently used in automatic control systems or networked with computers. Perform automatic adjustment and control of flow or other parameters.

Wedge flowmeter Vs V-cone flowmeter

The wedge flow meter is a new type of flowmeter that began to be practical in the 1980s. Its detection part is a V-shaped wedge (also known as a wedge-shaped throttling part), and its sleek top angle faces downward. It is conducive to the smooth passage of liquids containing suspended particles or viscous liquids, and no stagnant flow occurs on the upstream side of the throttle. Therefore, it is especially suitable for the measurement of volume flow and mass flow in petroleum and chemical industries.

Scope of application:

- Suitable for measuring mud, coal tar pitch, coal water suspension and other high viscosity fluids;

- In the case of a very low pipeline Reynolds number (even as low as Re=500), the square root relationship between flow and differential pressure can still be maintained. The minimum Reynolds number of the orifice flowmeter is much larger than that of the wedge flow meter;

- Corrosive media can be measured. Because the differential pressure measurement uses a diaphragm type double-flange differential pressure transmitter, corrosive media cannot enter the pressure guiding tube and the differential pressure transmitter. Therefore, only the wedge-shaped throttling is processed by corrosion-resistant materials It can make the instrument measure corrosive media.

The V-cone flowmeter is a new type of differential pressure flow meter with high precision and high stability. Like other differential pressure meters, it is also based on the principle of flow continuity and Bernoulli’s equation to calculate the fluid flow rate.

Scope of application:

Because the V-cone flowmeter can uniform fluid distribution curve. Therefore, compared with other types of differential pressure flow meters, the requirements for the upstream and downstream straight pipe sections are small. It is recommended to leave 0-3D straight pipes upstream and 0-1D straight pipes downstream. When the user’s pipeline size is large, the pipeline price is high or the straight pipe section is not enough, the V-cone flowmeter will be the best choice.

So to sum up, there are differences in the scope of application of wedge flow meter and v-cone flowmeter. The former can maintain the square root relationship between flow and differential pressure at very low pipeline Reynolds number. The latter can be used when the pipe size is large or the straight pipe section is not enough.

Extended reading: What Is A Venturi Flow Meter?

You may like:

Sino-Inst offers Wedge Flow Meters.

A wide variety of Wedge Flow Meter options are available to you, such as brass, carbon steel. You can also choose from free samples.

Sino-Inst is Wedge Flow Meter supplier. Orifice plate flow meter products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, including 375 with ISO9001, ISO14001, and Other certification.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.