Ultrasonic fuel tank level sensor, also called non-contact fuel meter, is an electronic level transmitter, measuring continuous liquid level, fluid level, or oil level.

ULT-200A Ultrasonic Level Transmitter, taking the advantage of various many levels measuring instruments is a universal one characterized, by total digitalized and humanized design.

Fuel Tank Level Sensor has been an important product, in the Level Measuring Instruments market over the past year, and it was very popular in India, the United States, Saudi Arabia, Canada, and Malaysia.

New: SI-LT Magnetostrictive level transmitter with Local Digital Display

Features of Ultrasonic fuel tank level sensor

- Sensor: Low power consumption, easy to install and locate, standard 4-20mA output, can be used as level gauge alone.

- The probe can be made for IP68, anti-corrosion, explosion, small blind, low power consumption, large range 16 key operation.

- Human-Machine communication can be more efficient.

- Backup and recovery parameter set.

- Measure for level, volume, weight.

- Set a filter value to remove

- Output HART, it can be direct communication with other instruments.

- (Optional) Mini SD data collection and GPRS communication are optional.

Specifications of ULT-200A Ultrasonic fuel tank level sensor

| Item | Split Type Ultrasonic Level Transmitter |

| Sense Range | 3m; 5m; 8m; 10m; 12m; 15m; 20m; 25m; 30m |

| Blind Area | <0.3m-1.5m |

| Accuracy | ±0.3%F.S |

| Display | LCD |

| Resolution | 1mm |

| Keyboard | 16 key |

| Output | 4~20mA(standard); 0~20mA; 1~5V; 0~5V; 0-10V; 1-10V; RS485; HART; 4 relays (Contact capacity AC:5A 250V DC:10A 120V) |

| Consumption | <8W |

| Material | ABS |

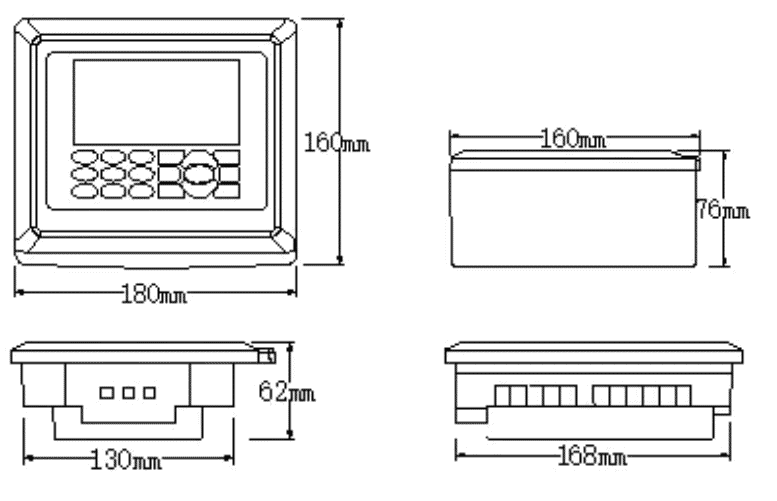

| Secondary Meter Dimension | 240mm×184mm×110mm |

| Sensor Size | Φ41×100×Φ30 (for range:1 m); Φ55mm×119mm×G1 1/2 (for range:3 m); Φ74mm×135mm×M60 (for range:3~15 m)’ Φ109mm×200mm×M30 (for range: 16~35 m) |

| Installation Size | G1 1/2(3m); M60x2 (5-15m); M30X1.5 (20-30m) |

| Sensor Cable | 10m (optional) |

| Operating Surroundings | normal temperature, normal pressure |

| Protection Degree | IP53 for instrument/ normal temperature, normal pressure |

Working Principle of the ultrasonic level transmitter

Video source: https://www.youtube.com/watch?v=WY6Bj3f6piE

Extended reading: level sensors for fuel tanks

Ultrasonic fuel level sensors for challenging applications

All Sino-Instrument ultrasonic fuel level sensor models provide continuous, non-contact measurement (like radar), making them ideal for measuring fluids found in machine tools, like oil or hydraulic fluid, that cannot be tainted by the introduction of foreign materials.

Our ultrasonic fuel level measurement modules can be programmed to account, for oscillations and turbulence, that could otherwise lead to incorrect readings.

Measurement clear to the bottom of the tank can be realized.

Extended reading: Diesel fuel tank level gauges & indicators

Sino-Instrument’s ultrasonic tank level sensors feature an extremely broad operating temperature range.

They can operate in outdoor applications or extreme environments like commercial car washes, or outdoor fuel generators with no loss of performance or accuracy.

Tank Level Measurements

Sino-Instrument’s ULT series level transmitters offer cost-effective, continuous level measurement and a wide range of features, to handle almost any tank level management task.

Read more about: 7 Level Senors for Tank Level Measurement

Chemical Level Measurement

Many common chemicals can damage level sensors. Even stainless steel sensors can be quickly corroded by some chemicals.

Transducer elements and the adhesives that bond them to housings are especially susceptible to corrosive liquids and gases.

Special chemically resistant polymer housings are necessary for these environments.

Simply coated transducers or partially protected sensor housings may not offer enough protection.

Tank Level Display

A simple display will provide tank level in feet or meters.

With more advanced displays,

you can convert simple level measurements to engineering units like gallons, liters, pounds or kilograms.

Tank Level Alarms

Many tank level applications require alarms to be sounded when levels get above or below a certain point.

Tank Level Control

Ultrasonic level sensors may send measurements to a tank level controller, or ToughSonic sensors may control tanks directly using switches and relays.

Advanced Tank Level Measurements

Tank level measurements are sometimes complicated by conditions in the tank.

Structural obstacles such as supports or mixing equipment might be in the sensor measurement path.

Similarly, spray or foam can obscure the air-to-liquid interface that ultrasonic sensors detect.

These applications require more advanced sensor capabilities.

You may like:

How many types of level sensors are there?

There are many different kinds of level measurement transmitters, including:

- Capacitance

- Hydrostatic

- Magnetic

- Radar

- Ultrasonic

- Guided Microwave

Each of these transmitters works in different ways, making them useful for different types of processes.

These transmitters use liquid stored in a tank or container, as a dielectric medium between two or more electrodes.

The energy capacity of the capacitor circuit increases, when there is more liquid and decreases if there is less liquid. By measuring the variations in the capacitance value, capacitance level transmitters can calculate the current fill level of the tank or container.

Extended reading: What is a capacitive liquid level sensor?

Also known as pressure level transmitters, these transmitters help in determining fluid contents of a container, by measuring the pressure of the resting body of the fluid within it. The greater the force of liquid, the greater the volume of fluid.

These transmitters use a magnetic object, which is suspended in a buoyant float.

This is usually in a narrow auxiliary column, to restrict lateral movements of the float.

While the float is on top of the liquid, the movement of the float is measured by a different magnetic device.

This allows a precise and stable fill level to be transmitted. This method is suitable for continuous measurement, owing to the tendency of the float to rise or sink based on the liquid level.

These transmitters work on the principle of radar by using radio wave emissions.

These transmitters are normally mounted at the top of a tank filled with a liquid.

The transmitter sends a radar signal into the liquid and receives a reflection of the signal.

The transmitters then analyze the current fill level of the tank based on the time taken by the transmitted signal to return.

In this type of transmitter, an ultrasonic transducer is mounted at, or near the top of a container containing liquid.

The transducer sends out an ultrasonic pulse.

The pulse hits the surface of the liquid and gets reflected.

The sensor then calculates the fill level based on the time between the transmitted and received signal.

Magnetostrictive level sensor, is the best choice for water level measurement, diesel tank level, and fuel tank level measurement.

These transmitters work by sending a microwave pulse, through a sensor cable or rod.

The signal hits the surface of the liquid, and travels back to the sensor,and then to the transmitter housing.

The electronics integrated into the transmitter housing determine the filling level based on the time, taken by the signal to travel down the sensor and back up again.

These types of level transmitters are used in industrial applications, in all areas of process technology.

Learn more about Diesel fuel tank level gauges & Indicators

Featured Continuous level sensors

Sino-Instrument offers 20 ultrasonic level detectors products.

About 13% of these are ultrasonic level transducers, 4% are ultrasonic level indicators.

A wide variety of ultrasonic level detector options are available to you, such as free samples, paid samples.

Sino-Instrument is the most important platform for Fuel tank level sensor product online wholesales,

they produce qualified Fuel tank level sensor and support OEM and customized designs.

Then How to choose a suitable Fuel tank level sensor products from Sino-Instrument?

Many customs rank power supply, and product name, accuracy as the most important factor,

For the power supply, you can choose dc24v, (standard 24vdc) and 12~36vdc.

The most important product name are level gauge, water level sensor, and diesel fuel tank level sensor,

The popular accuracy is 0.3%, 0.1% optional and 10mm.

Sino-Instrument is ultrasonic level transmitter suppliers, located in China.

Ultrasonic level detector products are most popular in North America, Mid East, and Eastern Europe.

The United States, and India, which export 99%, 1%, and 1% of ultrasonic level transmitter respectively.

You can ensure product safety by selecting from a certified supplier, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.