Differential pressure sensors are used to Optimize Filtration Monitoring in different applications.

Ever wonder how your water stays clean or your air pure? It’s the work of top-notch filtration monitoring systems, made efficient by small but vital devices called differential pressure sensors. This blog post will walk you through what these sensors are, their working principle, and their key role in filtration monitoring. We’ll also highlight the tangible benefits they bring to your business. Ready to enhance efficiency and reduce costs? Let’s delve into the world of differential pressure sensors.

Understanding Differential Pressure Sensors

Differential pressure measurement is the difference in pressure between two points in a system. This data is crucial in many applications, filtration Monitoring systems being one of them.

A differential pressure sensor is a special instrument used to measure the pressure difference between two points in a system. It contains important parts like diaphragms, strain gauges, or capacitive elements. These sensors come in different types, such as diaphragm-based, piezoresistive, and capacitive. Each with its own benefits and uses. Unlike regular pressure sensors that measure absolute or gauge pressure, differential pressure sensors specifically concentrate on the pressure difference between two points.

More about: Working Principles Of Differential Pressure Sensors

The Crucial Role of Filtration Monitoring

Filtration is like a superhero in the world of industries. It protects systems by separating the wanted from the unwanted, whether it’s clean water from contaminants, pure air from pollutants, or precious oil from impurities.

Monitoring the process is key. Without proper filtration monitoring, systems could run into issues. Clogged filters might go unnoticed, leading to decreased performance or even system breakdowns. This could result in downtime or costly repairs, a headache no one wants.

Many industries, from water treatment to HVAC, from oil and gas to food and beverage, all rely heavily on filtration processes. Without adequate monitoring, they can’t ensure optimal operations or the quality of their products.

So, how do we prevent these issues? This is where differential pressure sensors become a star player. Read on to discover how these trusty devices help keep your filtration process in check.

Application of Differential Pressure Sensors in Filtration Monitoring

Differential pressure measurement is the difference in pressure between two points in a system.

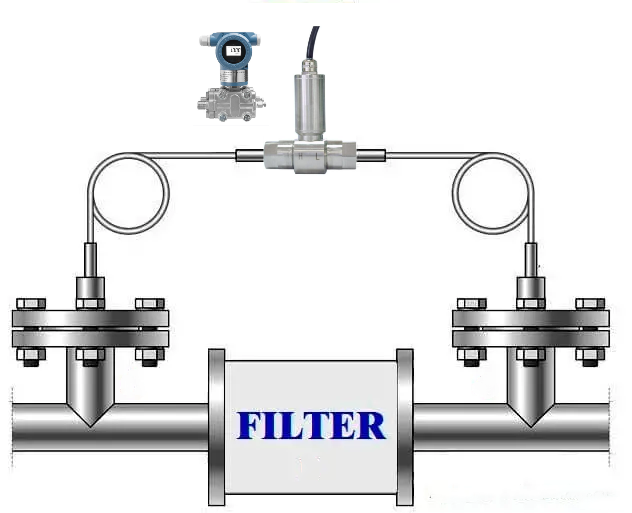

For filter applications, the upstream side [A] is before the filter [B] and the downstream side [C] is after the filter. Differential pressure sensors can be used to monitor the cleanliness of filters in liquid or gas applications.

Working principle

- Upstream pressure (usually line pressure or inlet water pressure) drives the media through the filter. A line was installed before the filter and connected to the high side of the sensor.

- Filters remove contaminants from the media.

- The downstream or outlet pressure then directs the media through the system with less contaminants than before. A line is installed at the lower end of the sensor to monitor the differential pressure.

- When there is no contamination in the filter, the system will measure a differential pressure of 0 PSI. As the filter clogs, the pressure on the downstream side decreases. This results in a greater differential pressure between the high and low sides. When using a differential pressure transducer, the unit provides a linear output signal based on the differential pressure.

Example:

Consider a system where a 100 PSI pump equipped with a filter is used to purify drinking water. The filter should be replaced when the downstream side of the system pressure drops to 80 PSI. In this scenario, the sensor is calibrated with a 100 PSI line pressure and a 20 PSI differential pressure, using a 24VDC power supply and emitting a 4-20mA output signal.

When the system operates with a clean filter, the output signal is at the lower limit of 4mA. However, as the downstream pressure decreases, the output signal will increase. When the downstream pressure reduces to 80 PSI, the sensor’s output signal will reach its full scale of 20mA.

Connected to a controller, this output informs the operator when it’s time to replace the filter. With this set-up, you have a smart, efficient, and effective system ensuring the provision of clean drinking water.

Featured Differential Pressure Sensors

Piezoresistive Differential Pressure Transmitter utilizes the piezoresistive effect of semiconductor silicon materials. Realize accurate measurement of differential pressure.

Differential pressure (DP) level transmitter is a perfect solution for tank level measurement. Flanges, seal diaphragms, capillaries, and DP transmitter are often used to measure liquid levels.

Flange Mounted Differential Pressure Transmitter is also called single flange DP level transmitter. For liquid, gas or vapor pressure measurement.

Quickly measure the positive, negative or DP of air or non-corrosive gas. Sino-Inst supplies Differential Pressure Gauges made in China. DWYER 2000 Differential Pressure Gauges, Magnehelic differential pressure gauges are also available.

Benefits of Using Differential Pressure Sensors for Filtration Monitoring

Wondering why you should consider differential pressure sensors for your filtration monitoring needs? Here’s the scoop!

- Cost Savings: Picture this – you’re changing filters only when necessary, not too soon or too late. That’s efficient use of resources, which translates into savings. Plus, by preventing breakdowns, you avoid costly repairs.

- Increased Efficiency: By ensuring your filter isn’t clogged, the fluid flows smoothly, and your system works at peak efficiency.

- Reduced Downtime: With these sensors, you get a heads-up before your filter causes a problem. That means you can schedule maintenance and avoid unplanned downtime.

- Improved Safety: In some industries, a faulty filtration process can pose a risk to safety. By monitoring pressure differences, you can detect and address issues promptly, keeping your work environment safer.

In a nutshell, differential pressure sensors are a smart investment for any business. They help keep your operations running smoothly, efficiently, and safely, saving you both time and money. So, what are you waiting for? Get started with differential pressure sensors today!

More Measure and Control Solutions

Low Cost Differential Pressure Sensor – Solve Big Problems!

Oxygen Cleaning Pressure Sensor – No Oil, No Corrosion, No Impurities

The Role of Dew Point Meter for Compressed Air Systems

More than Just Compressed Air! What Gases Can the Dew Point Meter Detect?

Top 1 Guide to Dew Point Measurement

What Is a Doppler Flow Meter?

At Sino-Inst, we understand the importance of quality and precision in your industry. With our extensive experience and knowledge, we offer a broad range of pressure sensors, including custom solutions tailored to your specific needs.

Are you ready to unlock the potential of differential pressure sensors in your filtration processes? Don’t hesitate to reach out to our team. We’re here to answer your questions, provide guidance, and help you select the best sensor for your application.

Make the smart choice. Choose Sino-Inst. Let’s take the first step towards improved filtration monitoring today!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.