Torque transducers are essential tools in many industries that rely on precise measurements of rotational forces. These devices play a crucial role in measuring the torque produced by engines, motors, and other rotating systems.

Whether you’re working in the automotive, aerospace, or manufacturing industry, understanding what a torque transducer is and how to choose the right one is crucial for optimizing performance and ensuring accuracy.

In this blog post, we’ll explore everything you need to know about torque transducers, including their types, applications, and factors to consider when selecting one for your specific needs.

What is torque?

Torque is a term used to describe the twisting or rotational force applied to an object. You can think of it as the force that causes an object to rotate around a fixed axis, like a wheel turning on an axle.

Torque is measured in units of force times distance, such as pound-feet or newton-meters.

In everyday life, you might experience torque when tightening a bolt with a wrench or using a crank to turn a wheel.

In the world of engineering and physics, torque plays a critical role in understanding how machines and engines work, and how to measure and optimize their performance.

More about torque definition and calculation.

What Is a Torque Transducer?

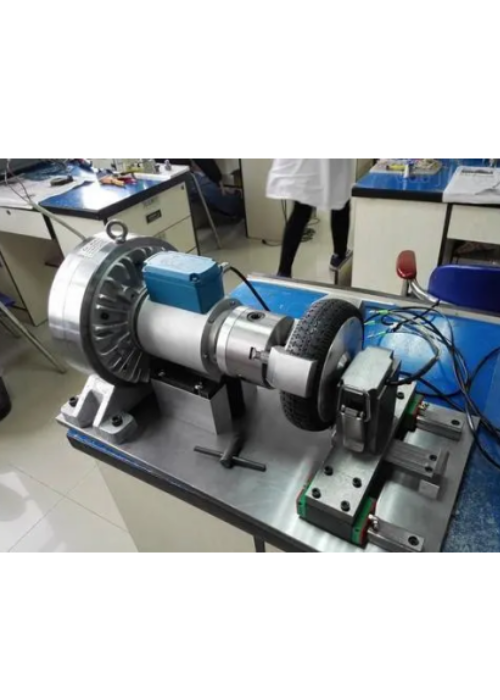

A torque transducer is a device that measures the amount of twisting or rotational force (torque) applied to a rotating system.

It’s like a scale for measuring the torque produced by machines and engines.

Torque transducers can be used in a wide range of industries, such as automotive, aerospace, and manufacturing, to optimize performance and ensure accuracy.

There are different types of torque transducers, including strain gauge, magnetoelastic, and optical, which work by different principles to measure torque.

By providing accurate measurements of torque, torque transducers help engineers and technicians understand how machines and engines are performing and make improvements where necessary.

Torque Transducer Measurement Principle

The measurement principle of a torque transducer is all about detecting and measuring the twisting or rotational force applied to a rotating system.

Torque transducers work by using different methods, such as strain gauges, magnetoelasticity, or optical technology, to sense the amount of torque being applied.

For example, strain gauges work by measuring the electrical resistance of a metal strip that changes as it stretches or compresses in response to the applied torque.

The magnetoelastic type, on the other hand, uses a magnet and a magnetic field to sense changes in the shape of a metal element.

In each case, the torque transducer converts the twisting force into a measurable electrical signal, which can be analyzed and used to optimize the performance of the machine or engine.

Types of torque transducers

| Type of Torque Transducer | Measurement Principle | Advantages | Disadvantages |

| Strain Gauge | Uses metal strip to change resistance when twisted | Accurate and cost-effective; Good for low-torque applications | Can be sensitive to temperature changes |

| Magnetoelastic | Uses magnetic field to measure torque | Highly accurate and durable; Good for high-torque applications | Can be expensive |

| Optical | Uses light to detect changes in material’s properties | Highly accurate and non-contact; Good for high-speed applications | Can be expensive and sensitive to vibration |

| Rotary Transformer | Uses two coils and a magnetic field to measure torque | Highly accurate and durable; Good for high-torque applications | Can be expensive and sensitive to temperature changes |

| Hybrid | Combines two or more principles for more precise measurement | Can offer advantages of multiple types | Can be more complex and expensive |

Static / Reaction Torque vs. Rotary Torque

When it comes to measuring torque, there are two main types: static/reaction torque and rotary torque.

Static torque refers to the twisting force applied to a non-moving object, such as a bolt or a nut.

Rotary torque refers to the twisting force applied to a rotating object, such as a motor or an engine.

Static torque measurement is important for applications where a component needs to be tightened to a specific torque value, such as in the automotive or aerospace industry.

Rotary torque measurement, on the other hand, is critical for assessing the performance of rotating machinery and ensuring its efficiency and longevity.

Both static and rotary torque measurement have their own unique challenges and require different types of torque transducers.

Understanding the differences between these two types of torque measurement is essential for selecting the appropriate torque transducer for a specific application.

Featured Torque Transducers for Sale

Industrial Applications of Torque Transducer:

Here are some common industrial applications of torque transducers:

- Automotive industry: measuring the torque applied to bolts during assembly process.

- Aerospace industry: measuring the torque in engines, turbines, and other rotating machinery.

- Energy industry: measuring the torque in wind turbines, generators, and other equipment.

- Manufacturing industry: measuring the torque in production equipment such as lathes and drills.

- Medical industry: measuring the torque applied to medical instruments during surgical procedures.

- Research and development: testing the performance and characteristics of new materials and products.

- Robotics: measuring the torque applied to robotic joints and motors to ensure accuracy and safety.

These are just a few examples of the many industrial applications of torque transducers.

How to choose a Torque Transducer for your application?

Choosing the right torque transducer for your application can be a daunting task, as there are many factors to consider.

Here are some key factors to keep in mind when selecting a torque transducer:

By considering these factors, you can select a torque transducer that is appropriate for your specific application and provides accurate and reliable measurements.

More Torque and Pressure Measurement Solutions

Stationary Torque Transducers

Small Pressure Transducer/Sensor-Low Cost-High Performance

What’s the Difference Between a Pressure Transducer and a Pressure Switch?

What Is Flush Diaphragm Pressure Transducer? When Use?

Natural Gas Pipeline Monitoring: Pressure-Temperature-Flow

Different Types of Pressure: Absolute, Gauge, Sealed Gauge and Differential Pressure

Conclusion

Torque transducers are an essential tool for measuring torque in various industrial applications. Whether you are in the automotive, aerospace, energy, manufacturing, or medical industry, selecting the right torque transducer is crucial for ensuring optimal performance, safety, and reliability.

By considering factors such as torque range, accuracy, sensitivity, speed, signal output, environment, and durability, you can select a torque transducer that meets the unique requirements of your application.

If you need to purchase a torque transducer or have any related technical questions, feel free to contact Sino-Inst. We specialize in providing high-quality torque transducers that are reliable, accurate, and durable. Our team of experts is always ready to assist you in selecting the right torque transducer for your specific needs. Contact us today to learn more!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.