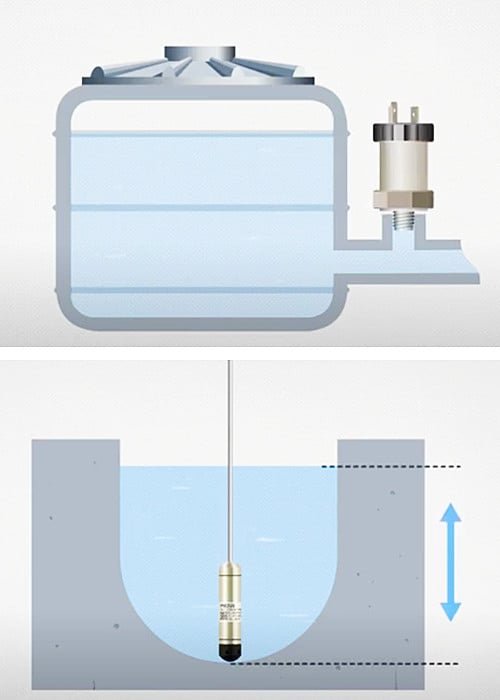

The Hydrostatic Pressure Transmitter measures the hydrostatic pressure exerted by a hydrostatic head. Use these hydrostatic pressure transmitters to measure the liquid level in storage tanks, processing vessels, collection tanks, pump inlet heads. And other applications use hydrostatic pressure to determine the liquid height. The pressure transmitter used to measure liquid level can be called: pressure liquid level transmitter. It is mainly used for open non-pressure vessels. One is submersible type, and the other is flat film installation.

You may often hear Hydrostatic Pressure Transmitter or static pressure transmitter. So are they the same? What is their role? Next, the Sino-Inst engineer will take you to take a look.

Featured Static Pressure/Hydrostatic Pressure Transmitters

Hydrostatic Level Measurement Calculation

Liquid level sensors based on hydrostatic liquid level measurement usually measure the filling height of the container according to the following principles:

The liquid passes its specific gravity and gravity. The gravity increases with the filling height. This kind of gravity, which increases with the increase of the filling height, is called a liquid column.

So, if a static pressure type liquid level sensor is selected. This transmitter will measure the corresponding height of gravity of the liquid column as the hydrostatic pressure. Based on the measured hydrostatic pressure and product density. Now you can also calculate the filling height of the container.

Extended reading: What is flush diaphragm?

Hydrostatic level measurement has enjoyed a high reputation for many years and represents 40% of the market share. It is by far the most common electronic liquid level measurement method. Most importantly, it is well known for its high reliability and low installation cost. Therefore, users think that hydrostatic level measurement is very simple and powerful.

Extended reading: Silicon Pressure Sensor

Hydrostatic Level Transmitter Advantages and Disadvantages

About Hydrostatic level transmitter advantages and disadvantages, we do a simple analysis here. If you want to know more about the advantages and disadvantages of level transmitters. Please refer to Sino-Inst Level Transmitters.

Advantages

- High measurement accuracy;

- The ultra-high range can be customized up to 1000 meters.

- Easy to install;

- The signal can be transmitted remotely;

- The corrosion of various media can be resisted by choosing different materials;

- Suitable for explosion-proof occasions;

- Low cost;

Disadvantages

- The measurement signal needs to be converted;

- When the measuring range is greater than 5 meters, it is impossible to measure the high temperature medium temperature exceeding 125 ℃;

- The density of the measuring medium must be uniform.

Extended reading: High accuracy pressure transducers

Static Pressure Effect in Pressure Transmitter

Static pressure is easy to understand. It is the maximum bearable pressure.

For example, the differential pressure range you measure is 0-1KPa. This pressure may be that the pressure on one side is 0. The other side is 1KPA. At this time, the maximum static pressure is 1KPA.

The differential pressure range you measure is 0-1KPa. This pressure may be that the pressure on one side is 10000KPa and the other side is 10001KPA. At this time, the maximum static pressure is 10001KPA.

Although the measuring range is the same. The pressure displayed by the transmitter is the same. But the static pressure value of the two pressure transmitters is completely different. The sensor selected for the transmitter is also different.

The verification of the influence of the static pressure of the pressure transmitter is as follows:

- Connect the high and low pressure chambers of the transmitter to the atmosphere and measure the lower limit of output.

- Introduce the static pressure to slowly change from atmospheric pressure to rated working pressure. After stabilizing for 3 minutes, measure the lower limit of output. And calculate the difference of the lower limit of output to atmospheric pressure.

- Transmitter with adjustable input range. Except for special regulations, the static pressure influence verification should be carried out on the smallest range. After verification, it should be restored to the original range.

Extended reading: Best Price Ceramic Pressure Sensor

High Static Differential Pressure Transmitter

The high static pressure differential pressure transmitter is used to measure the level, flow and pressure of liquid, gas or steam in a high working pressure environment. Then it is converted into a 420mA DC signal output. The HP intelligent type can communicate with the HART handheld communicator. Use it to set up, monitor or form an on-site monitoring system with the host computer.

Influence of static pressure

①Zero point: ±0.2% URL under 31027kPa static pressure. The zero point error can be corrected online through zero adjustment.

②Range: can be corrected to ±0.25% output reading/6895kPa

In addition, the excellent static pressure performance of the monocrystalline silicon differential pressure transmitter is also better than that of the capacitive products on the same occasion. The optimal static pressure error can be controlled within ±0.05%/10MPa.

Extended reading: Pressure Sensor Applications In Various Industries

Frequently

Asked

Questions

Hydrostatic Pressure Transmitter Price

The price of Hydrostatic Pressure Transmitter is not much different from that of ordinary pressure transmitters. The price of Hydrostatic Pressure Transmitter can be determined according to the customer’s parameters. About USD150~350.00.

Sino-Inst offers over 20 Static Pressure/Hydrostatic Pressure Transmitter. A wide variety of Static Pressure/Hydrostatic Pressure Transmitter options are available to you. Such as free samples, paid samples.

Sino-Inst is a globally recognized manufacturer of Static Pressure/Hydrostatic Pressure Transmitters, located in China. Sino-Inst sells through a mature distribution network that reaches all 30 countries worldwide. Static Pressure/Hydrostatic Pressure Transmitters products are most popular in Europe, Southeast Asia, and Mid East. You can ensure product safety by selecting from certified suppliers. With ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.