What is Strap on Ultrasonic Flow Meters?

Strap on Ultrasonic Flow Meter is also often called Clamp On Type Flow Meter. The unique feature of Strap on Ultrasonic Flow Meter is that the sensor does not need to be in contact with the medium, which is different from other flow meters.

- Clamp on type, No need to cut the pipe or do any other changes.

- No professional product knowledge required, installation and measurement can be done based on the guide.

- No moving parts or pressure changes involved, installation can be done without stop provide.

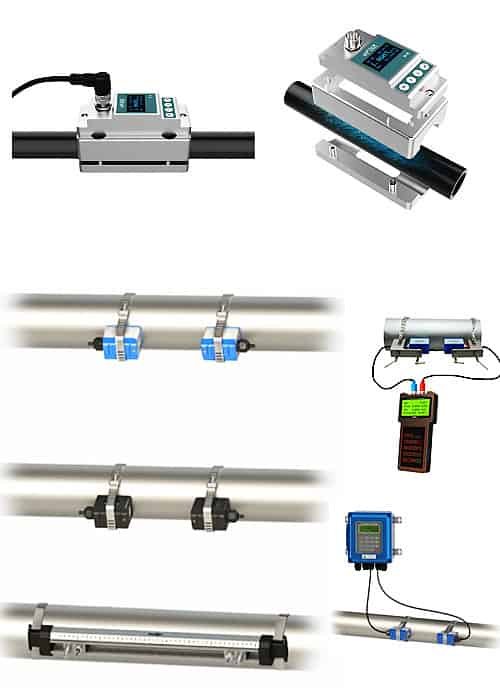

Featured Strap on Ultrasonic Flow Meters

Strap on Ultrasonic Flow Meter Working Principle

The strap-on ultrasonic flow meters supplied by Sino-Inst are based on the working principle of the time difference method.

Transit Time Ultrasonic Flow Meter adopts the measurement principle of the time difference method. It uses the ultrasonic wave emitted by the sensor to propagate in the flowing fluid. The sound wave propagation speed in the downstream direction will increase, and the backward direction will decrease. In the same propagation distance, there will be different transmission times. According to the difference between the transmission time and the measured The relationship between fluid velocity measures the fluid velocity.

The flow rate of the fluid is different in different positions in the tube. The flow rate in the center of the tube is faster than the flow rate near the wall of the tube. The flow velocity distribution of the fluid in the pipeline can be represented by the flow velocity cross-sectional distribution diagram.

By setting the flowmeter and considering the cross-sectional distribution of the flow velocity, the average flow velocity can be calculated. Then the volume flow of the fluid can be obtained according to the cross-sectional area of the pipe.

Notes:

V measure fluid velocity

M ultrasonic reflection times

D pipe diameter

θ The angle between the ultrasonic signal and the fluid

T up The time when the downstream sensor transmits the signal to the upstream

T down Time from upstream sensor to downstream

ΔT = T up – T down

Guess You’ll Like: Ultrasonic flow meters types & technical guide

Strap on Ultrasonic Flow Meters Application

Sino-Inst concentrates on the development of flow measurement technology. The products serve real-time flow measurement and participation process control in the production process. The main customer industries are the chemical production process, fine chemical production, cleaning industry, beverage industry, etc.

With the world’s most advanced time measurement chip (time resolution of 50ps), Sino-Inst has developed a series of straps on ultrasonic flow meters.

It takes only 2-3 minutes to complete the whole process from installation to measurement. It also adopts the current popular OLED display, which makes it easy to read in low light conditions.

Strap on Ultrasonic Flow Meters is widely used in the production process flow measurement and monitoring. The application of the product continuously and effectively controls the flow of the fluid, so as to improve the yield of the product and even save the input of the personnel, bringing benefits to the production enterprise.

Strap on Ultrasonic Flow Meters can meet different pipe requirements: stainless steel pipe, carbon steel pipe, copper pipe, plastic pipe(PVC, PVDF, PPR, PPH, HDPE, etc.).

Extended reading: non contact flow meter

Strap on Ultrasonic Flow Meters also satisfies different clean fluid measurements: various acids, alcohols, chemical solvents, alcohol, beverage water, Coca-Cola water, etc. Strap on Ultrasonic Flow Meters output signal, such as 4-20mA. The flow signal can be connected to a paperless recorder. Carry out multi-channel flow signal monitoring. What Is A Paperless Recorder?

Extended reading: Fluid flow meter types

Extended reading: Battery operated electromagnetic flow meter-GRPS-new irrigation water flow meter

Installation Guidelines

Frequently

Asked

Questions

Extended reading: metal tube flow meter

Sino-Inst, Manufacturer for Strap on Ultrasonic Flow Meters. It can measure a single sound-conducting liquid medium of DN 5—6000mm. It can measure even liquids such as water, seawater, oil, and slurry.

Sino-Inst’s Strap on Ultrasonic Flow Meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.