Stilling Wells for Radar Level Measurement

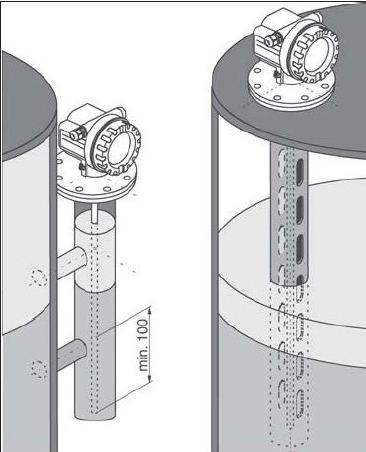

Stilling Wells is our complementary tool in radar level measurement. Simply put, Stilling Wells is a metal pipe installed under the radar level meter. In many working conditions, the radar level meter is installed inside the storage tank. In order to concentrate microwave pulses and reduce scattering, one of the methods adopted is to install them in Stilling Wells. Especially for occasions where the liquid level fluctuates greatly or foam is generated.

When do we need to use Stilling Wells?

Usually, the radar level meter is installed in Stilling Wells because the interference signal caused by certain factors has a great influence on the real signal, resulting in measurement errors or even failure to measure. The radar level meter is installed in the Stilling Wells, which can avoid the influence of the interference signal on the real signal and ensure the accuracy of the measurement.

So, under what circumstances will the radar level meter be installed in Stilling Wells?

Situation 1: There are obstacles in the storage tank or large foam and fluctuations on the liquid level. In this case, interfering signals can significantly affect the measurement.

Situation 2: The dielectric constant of the medium is low, and the reflected echo is too small to accurately measure the liquid level. Using the radar level meter installed in Stilling Wells can increase the reflected echo energy and ensure accurate measurement.

Using Stilling Wells installation (Stilling Wells or bypass pipe), you can avoid the impact of obstacles, foam, liquid surface fluctuations in the container on the measurement.

Stilling Wells can only measure medium with good fluidity. Viscous medium cannot be measured with Stilling Wells.

Advantages of Stilling Wells for Radar Level Measurement:

The advantage of Stilling Wells measurement is that the liquid level in the pipe is stable and not disturbed by external fluctuations.

Avoid interference from obstacles inside the container.

Reduce the influence of foam and air turbulence on the measurement.

Increase signal reflection strength.

For the case where the measured object has boiling or turbulent liquid level, or the dielectric constant of the measured medium is small, measures such as Stilling Wells should be used to ensure the measurement accuracy.

The accuracy of the radar level meter differs under actual application and reference conditions. The main reason is that the tank itself has become part of the measurement system. The ability to achieve accuracy is determined by the interference of the microwaves by the tank and its internal obstructions.

After the pressure spherical tank is built, the draft tube becomes a part of the tank body. Its manufacturing process level directly affects the measurement accuracy of the radar level meter.

The electromagnetic wave emitted by the radar level meter propagates along a straight line. When interference is encountered in Stilling Wells, a reflected echo will be generated, and the echo amplitude is small. On the contrary, if the smoothness of the inner wall of the pipe is not ideal, it will show a reflection echo with a large amplitude.

Read More about: List of Differences: Radar vs Ultrasonic Level Measurement

Featured Radar Level Meters

Radar level meter installation standards

The installation position of the radar level meter affects the measurement accuracy. Pay full attention to several issues:

- Radar level meter The distance between the tank hole and the tank wall is greater than 15% of the height between the flange sealing surface and the tank bottom plate, so it is limited to using guided waves to close the pipeline.

- In order to ensure that the sound signal enters the middle of the storage tank unhindered, the total length of the flange and pipe joint of the radar level meter socket is less than 250mm.

- If there is a waveguide; the waveguide should be horizontally downward, the allowable error ≤ 0.5; the verticality should be 1.

- Installation and connection should take into account the strength of the tank roof so as not to cause variable displacement.

- The radar wave path should avoid internal obstacles, such as brackets, heating wires, stirring rods, etc.

- Consider liquid level conditions and avoid formation of air bubbles such as turbulence at the discharge end.

Radar level meter production requirements

When the storage tank is a floating roof tank or a spherical tank, a waveguide shall be used.

When the medium level fluctuates or foams, the waveguide should also be actively added.

The waveguide is not purchased together with the equipment supply, and should be manufactured on site by the supervisory unit according to the specific working conditions.

The specific conditions for manufacturing Stilling Wells are as follows:

- Stilling Wells shall be constructed of stainless steel or carbon steel, and only stainless steel shall be used for spherical tanks.

- Stilling Wells should be complete. If it needs to be lengthened, the jacket welding method must be used. The gap is less than 1.0mm. There should be no welds or sharp edges on the inner wall of the welding. Otherwise, its accuracy will be affected.

- The bottom of the Stilling Wells is 100~150mm away from the bottom plate of the fuel tank. Then add a reflector radar inclined at 45°.

- In order to ensure that the liquid levels outside the Stilling Wells are equal, the Stilling Wells must be separated at the intersection holes, and the plane of the Stilling Wells section must be smooth, otherwise false liquid levels are prone to occur. The hole spacing should be appropriate and not too large, so as not to cause fluctuations in the liquid level in the pipe;

- It cannot be too small, and it is not very effective to ensure that the liquid level inside and outside the Stilling Wells is consistent.

Extended Reading: Case: High Temperature Radar Level Transmitter for Melted Salt-Solar Photovoltaic Power Station

Our experience:

Stilling Wells should be made of carbon steel or stainless steel. If it is used in spherical tanks, stainless steel must be used. This is the result of years of experience.

In addition, it is recommended that Stilling Wells be made into whole roots. If lengthening is required, the outer jacket welding method must be used. And the gap should be less than 1 mm. There must be no burrs and welds on the inner wall. Burrs and welds will interfere with the real echo signal and affect the measurement effect.

The last point, which is crucial, is directly related to whether the liquid level is true. Therefore, more attention is required. When making Stilling Wells, it is necessary to use the interval distance to cross the holes. The opening should not be too large, nor too small. If it is too large, the liquid level in the tank will fluctuate easily. If it is too small, the internal and external liquid levels of Stilling Wells cannot be guaranteed to be consistent.

Based on years of experience, some engineers have made a correspondence between the diameter and opening size of Stilling Wells. When the diameter of Stilling Wells is DN125, DN200, DN250 and DN300, the opening sizes of Stilling Wells are 0.1m, 0.4m, 0.8m and 1.2m in sequence.

The above three points are all the experience summarized by Sino-Inst. In addition, some materials have also mentioned that a certain distance should be kept between the bottom of the Stilling Wells and the bottom of the storage tank, and reflectors should be installed. If you have installation needs, you can find more relevant information or ask more relevant engineers.

In order to ensure the accuracy of radar level meter measurement, in addition to installing Stilling Wells, some can also install bypass pipes. You can choose the appropriate method according to your own working conditions.

More Tank Level Measurement Solutions

The radar level gauge is installed in the waveguide, which can avoid the influence of interference signals on the real signal, increase the reflected echo energy, and improve measurement accuracy. But not all media are suitable for measurement in the waveguide, and viscous media are not.

Therefore, when choosing to install a radar level gauge in the waveguide, it is necessary to analyze the medium and the working conditions to avoid useless work.

Many times, there is more than one way to solve a problem. When there is a problem in the measurement of the radar level gauge, we can think about it and see which solution is most suitable for our working conditions.

If we pay attention to efficiency, then we can find the simplest solution;

If we pay attention to cost performance, we can consider it from the perspective of cost and find the most suitable solution.

Sino-Inst is an instrument manufacturer specializing in R&D, production and sales of radar level meters and radar water level gauges. We supply high frequency radar level meters, explosion-proof radar level meters, FM radar level meters, guided wave radar level meters, pulse radar water More than 10000 level meters.

If you need to purchase radar level meters, or have any technical questions about the application and installation of radar level meters, please feel free to contact us.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.