Magnetic flowmeters are mainly used to measure the flow of conductive media with good fluidity. Magnetic flowmeters are divided into insertion type and pipeline type. Pipeline electromagnetic flowmeter and insertion electromagnetic flowmeter has the same requirements for installation. There are also different places. Generally speaking, there are requirements for the external environment and installation methods.

Step 1: Magnetic Flowmeter Installation environment requirements

In order to make the electromagnetic flowmeter work stable and reliable, the following requirements should be paid attention to when choosing the installation location:

- Try to avoid ferromagnetic objects and equipment with strong electromagnetic fields (large motors, large transformers, etc.). In order to prevent the magnetic field from affecting the working magnetic field and flow signal of the sensor.

- Install in a dry and ventilated place as much as possible. Avoid sun and rain. The ambient temperature should be -20 ~ +60 ℃. The relative humidity is less than 85%.

- There should be ample space around the flowmeter. Easy to install and maintain.

Extended reading: Ultrasonic Insertion Flow Meter for Lined/Large Pipes

Step 2: Magnetic Flowmeter Installation Location selection

The electromagnetic flowmeter can be installed on a horizontal pipe or a vertical pipe.

- Choose a straight pipe section filled with liquid, such as the vertical section of the pipeline (flow direction from bottom to top is appropriate) or a liquid-filled horizontal pipe (the lowest point in the entire pipeline is appropriate). The position must ensure that the pipeline is always filled with the measured fluid . In the process of installation and measurement, there must be no partial full pipe.

- Select the place where the fluid flow pulse is small. That is, it should be far away from pumps, valves, elbows and other local resistance parts.

- When measuring two-phase (solid, liquid or gas, liquid) fluids, choose a place that is not easy to cause phase separation.

- Avoid negative pressure at the measurement site.

- The diameter or circumference of the side pipe is easy to measure, and the ovality should be small.

- Straight pipe length: The length of the straight pipe on the upstream side of the sensor installation pipeline should be greater than or equal to 10D, and the downstream side should be no less than 5D.

- There are two methods for inserting the insertion point of the plug-in electromagnetic flow sensor: one is to insert it on the central axis of the pipe under test, and the other is to insert it at 0.25D where the inner wall of the pipe is the pipe.

- Vertical installation: when the sensor is inserted into the pipe, the angle between the vertical diameter of the pipe section and the pipe section should be less than 5°, which is suitable for measuring clean media with small pipe vibration.

- Tilt installation: the angle between the axis of the sensor and the axis of the pipeline being measured is 45°. It is suitable for liquid flow measurement with large pipe diameter and other impurities in the measuring medium. This installation method has low water resistance and is not suitable for entanglement.

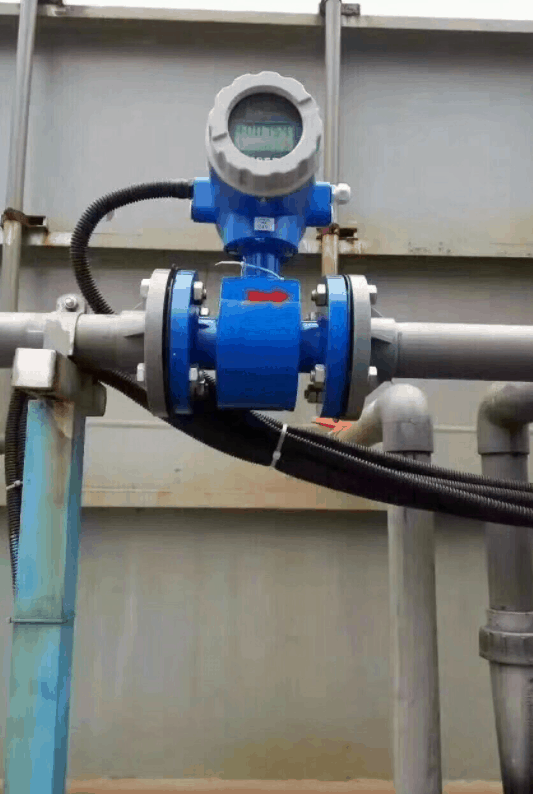

Step 3: Mounting flange for Magnetic Flowmeter Installation

A. Select the installation location and select the front and rear straight pipe sections of appropriate length. Cut the pipe section where the flowmeter is installed;

B. Weld a flange on each of the front and rear straight pipe sections. After adding gaskets at both ends of the sensor, connect the sensor to the flange with stud bolts (note that the direction of the arrow on the meter body should be consistent with the direction of fluid flow);

C. Weld the front and rear straight pipe sections of the sensor to the original pipe.

Note:

- When welding, ensure that the flange end face is perpendicular to the centerline of the pipeline;

- The place where the mounting hole pitch is larger is the meter rod mounting position. And the direction of the mounting holes of the two flanges should be the same;

- After the flange is welded, the pipeline should be cleaned up and there should be no welding slag and other sundries.

Extended reading: Magnetic Large Dia. Pipe Flow Meter

Step 4: Converter installation and connection cables

Power and signal wiring. Please refer to the product manual accompanying the goods.

The converter of the split electromagnetic flowmeter should be installed near the sensor where it is convenient for reading and maintenance. It can also be installed in the instrument room, and its environmental conditions can be much better than the sensor.

The distance between the converter and the sensor is limited by the conductivity of the measured medium and the signal of the signal cable. That is, the distributed capacitance of the cable, the cross-section of the wire, and the number of shielding layers. Use the information cable provided with the instrument by the manufacturer.

For liquids with lower conductivity and longer transmission distances, three-layer shielded cables are also specified.

The general instrument “Instruction Manual” gives the corresponding transmission distance range for liquids with different conductivity.

When a single-layer shielded cable is used for industrial water or acid-base liquids, the transmission distance is usually 100m.

In order to avoid signal interference, the signal cable must be worn separately in a well-grounded steel protection tube. Never put the signal cable and the power cord in the same steel pipe.

Guess you like: Insertion Magnetic Flow Meter-Large diameter online install

Special Magnetic Flowmeter Installation situation

For pipelines that do not allow flow interruption in the process, a bypass pipe should be installed and cleaned when the flow meter is installed. As shown in the figure, this device ensures continuous operation of the equipment system when the flow meter is withdrawn from use.

The inner diameter measured by the flowmeter should be consistent with the inner diameter of the pipe. If the inner diameter cannot be the same, the inner diameter of the pipe should be greater than the inner diameter of the flowmeter. And install a tapered tube or expansion tube with a cone angle not greater than 15 between them, as shown in the figure.

When the flowmeter is installed inclined or vertically, the flow direction should be from top to bottom, as shown in the figure.

All Magnetic Flowmeter Installations. It cannot be described in detail here. If you encounter problems with the Magnetic Flowmeter Installation. Please contact our engineers in time. We will guide the Magnetic Flowmeter Installation for you.

Featured Magnetic Flowmeters for Sale

Frequently

Asked

Questions

More Flow Measurement Solutions

Sino-Inst offer over 50 Magnetic Flow Meters, with Best Price.

A wide variety of Magnetic Flow Meters options are available to you, such as free samples, paid samples.

About 13% of these are magnetic flow meter, 14% are Insertion Magnetic Flow Meter, 25% are Venturi flow meter, 13% are ultrasonic flow meter, and others are Liquid Turbine Flow Meters.

Electromagnetic flowmeters can be divided into insertion electromagnetic flowmeters and pipeline electromagnetic flowmeters. The Magnetic Flowmeter Installation methods of insertion electromagnetic flowmeters and pipeline electromagnetic flowmeters have the same place, but there are also differences.

First of all, what we need is that the shielded wire of the electromagnetic flowmeter cannot be routed together with the cable, because this will cause interference. Under normal circumstances, the parameters of the inner head of the electromagnetic flowmeter are set in advance, so no other adjustments are required.

Magnetic Flowmeter Installation should avoid places where the temperature rises and falls too much, and places where there are magnetic fields and strong vibration sources.

Sino-Inst is Magnetic Flow Meters supplier, located in China. Magnetic Flow Meters products are most popular in North America, Mid East, and Eastern Europe. The United States, and India, which export 99%, 1%, and 1% of Magnetic Flow Meters respectively.

For how to install the electromagnetic flowmeter, the details of Magnetic Flowmeter Installation, if you have any questions and ideas, please feel free to contact us.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.