Micro Flow Meter is a micro oval gear flow meter. It is a kind of positive displacement flow meter. Suitable for flow measurement of micro liquid flow rate.

Micro Flow Meter for liquid low flow rate

- Micro flow 0.5ml/min

- All stainless steel 316L material

- 0.5% high precision, quantitative control

- Standard pressure 32Bar, high pressure can be customized, maximum pressure 1000Bar

- Suitable for various chemical liquids

Sino-Inst offers a variety of Oval Gear Flow Meters for flow measurement. If you have any questions, please contact our sales engineers.

Micro Flow Meter Specifications

Micro flow meter for low viscosity liquid

| Medium | Suitable for liquids, weakly corrosive chemical media For example: water; oil; glue; polyurethane, etc. |

| Precision | Standard accuracy +/-0.5% High viscosity accuracy can reach 0.2% |

| pressure | Standard withstand pressure 32Bar Accept high pressure customization, high pressure up to 1000Bar |

| temperature | Standard temperature range -30~80℃ The highest temperature of stainless steel series is 200℃ |

| Output | Hall & dry reed tube pulse output |

| powered by | 4~26VDC power supply |

| Stainless steel series | |

| Material | Shell: SS316L Gear: SS316L Bearing: SS316L |

| medium | Suitable for weakly corrosive liquids; such as: water; polyurethane |

| Aluminum alloy series | |

| Material | Shell: Anodized Aluminum Gear: Anodized aluminum Bearing: SS316L |

| medium | Non-corrosive liquid; such as: gasoline; aviation kerosene |

Micro flow meter for high viscosity liquid

| Medium | Suitable for liquids and high-viscosity media For example: water; oil; glue; polyurethane, etc. |

| Precision | Standard accuracy +/-0.5% |

| pressure | Withstand pressure 200Bar |

| temperature | Standard temperature range -30~80℃ The highest temperature of stainless steel series is 250℃ |

| Output | Hall & dry reed tube pulse output |

| Bearing | Ball bearing or PEEK bearing |

| powered by | 4~26VDC power supply |

| Stainless steel series | |

| Material | Shell: SS316L Gear: SS316L Bearing: SS316L |

| medium | Suitable for high-viscosity liquids; such as glue; polyurethane |

| Aluminum alloy series | |

| Material | Shell: Anodized Aluminum Gear: SS316L Bearing: SS316L |

| medium | Non-corrosive liquid; such as: gasoline; aviation kerosene |

| Model | CX-M2 | CX-M3 | CX-M5 | CX-M6 |

| Flow range | 0.5~150mL/min | 3~300mL/min | 5~1000mL/min | 0.5~100L/H |

| connection | G1/8 Female thread | G1/8 Female thread | G1/8 Female thread | G1/4 Female thread |

| medium | Suitable for various chemical liquids | |||

| Precision | 0.50% | |||

| temperature | -30℃ to 80℃ | |||

| pressure | 32Bar (high pressure can be customized) | |||

| Output | Square wave pulse | |||

| powered by | 4~26VDC | |||

| Material | Stainless steel material, aluminum material | |||

| Model | CX-M9 | CX-M12 | CX-M25 | CX-M40 | CX-M50 |

| Flow range | 6~600L/H | 0.3~30L/min | 0.5~100L/min | 10~250L/min | 15~500L/min |

| connection | G1/4 Female thread | G1/2 Female thread | G1 Female thread | G1.5 Female thread | G2 Female thread |

| medium | Suitable for various chemical liquids | ||||

| Precision | 0.005 | ||||

| temperature | -30℃ to 80℃ | ||||

| pressure | 32Bar (high pressure can be customized) | ||||

| Output | Square wave pulse | ||||

| powered by | 4~26VDC | ||||

| Material | Stainless steel material, aluminum material | ||||

Features of Micro Flow Meter

Quantitative control of micro liquid flow & flow monitoring.

The standard minimum flow rate of the micro flowmeter is 0.5ml/min.

The standard accuracy of the micro flowmeter is 0.5%. The cutting accuracy of the CNC machining center is 0.001mm.

For high viscosity media, such as glue, the accuracy can reach 0.2%.

The maximum range ratio of the standard product is 1:200, and the minimum range ratio is 1:100

The new M2.1 is the latest research and development. The flow range is 1~800ml/min, and the turndown ratio reaches 1~800.

To meet more working conditions, it is more suitable for test bench working conditions.

Two materials of stainless steel and aluminum alloy are available.

Extended reading: Micro flow meters for low flow liquids

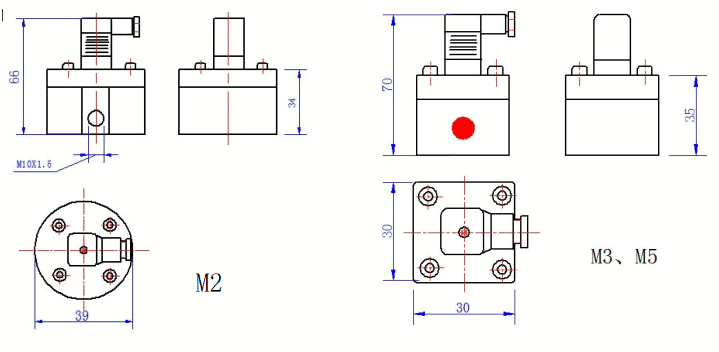

Micro Flow Meter Dimension

Extended reading:

What is the K-factor in a flow meter?

Cryogenic Flow Meters|Liquid Nitrogen-Liquid Oxygen-LNG fluids

Read more about: The Pros and Cons of Micro Motion Flow Transmitters

Clamp-on Micro Flow Sensor

Strap on flow meter X3 is a kind of ultrasonic external clamp-on flow meter. Strap on flow meter X3 is easy to install. Suitable for measuring pipe diameter Φ9.53~Φ90.

Strap on flow meter X3 can meet the needs of different pipe materials: stainless steel pipe, carbon steel pipe, copper pipe, plastic pipe, PVC, PVDF, PPH, PPE, etc.

Strap on flow meter X3 almost meets the measurement of different clean fluids: various acids, alcohols, chemical solvents, alcohol, drinking water, Coca-Cola water… etc.

| Product | Strap on Flow meter |

| Model | X3 |

| Flow range | 0.1m/s~5.0m/s |

| Accuracy | ±2.0% |

| Repeatability | 0.80% |

| Pipe size | φ6.35~φ90 |

| Data storage | Daily, monthly, and Annual. Flow Totalizer |

| Analog output | 4~20mA, Maximum load: 600Ω |

| Alarm output | DCT, Upper and lower limit alarm function(optional) |

| Communication | RS485,support Modbus communication protocol |

| Power supply | 24VDC |

| Cable length | 2.0m |

| Keypad | Four light touch buttons |

| Screen | OLED 128*64 displayscreen |

| Units | Metric and imperial units are available, Cubic Meters(m3), Liters(L), USA Gallons(GAL)/hour,/min,Default unit setting:m3/h |

| Totalizer | Six bit digit |

| Piper material | Stainless steel pipe, carbon steel pipe, copper pipe, plastic pipe |

| Case material | Aluminum alloy |

| Environment temp. | 0℃~50℃(32°F~122°F) |

| Medium temp. | 0℃~50℃(32°F~122°F) |

| Environment humidit | 0-95% relative humidity, without condensation |

| IP Grade | IP54 |

Read more about: Strap on flow meter X3

More Featured Liquid Flow Meters

Frequently

Asked

Questions

Related Blogs

Sino-Inst, Manufacuturer for Micro Flow Meters. For example: crude oil flowmeter, diesel flowmeter, gasoline flowmeter.

Sino-Inst’s Micro Flow Meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

Micro Flow Meter for Low&high Viscous liquids, oils-low flow

Micro Flow Meter is a micro oval gear flow meter. It is a kind of positive displacement flow meter. Suitable for flow measurement of micro liquid flow rate.

Product SKU: Micro Flow Meter

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 200

Price Valid Until: 2059-09-30

Product In-Stock: PreOrder

5