Pipe flow meters are the unsung heroes of fluid management, helping you accurately measure flow in closed pipes. These nifty gadgets come in various types. Like ultrasonic, portable, and magnetic flowmeters, each with their own benefits. Ultrasonic flowmeters, for example, use sound waves and can easily clamp onto a straight pipe for non-invasive flow rate measurement. From turbine to orifice plates and mass flow, there’s a perfect pipe flow meter for every application, whether it’s tracking upstream fuel flow or simply water gauging .

So, let’s analyze and compare pipe flow meters and discover their endless possibilities!

Pipe Flow Meter Basics

Understanding Pipe Flow

When it comes to pipe flow, it’s essential to know that not all fluid flow is created equal. There are two main types of flow you’ll come across: laminar flow and turbulent flow. Let’s break them down in a way that’s easy to understand.

Laminar flow is the smooth, orderly flow of fluid in a pipe. Picture a peaceful river, where the water glides effortlessly along. In laminar flow, the fluid’s layers slide past each other without much mixing, resulting in a low flow resistance.

Turbulent flow, on the other hand, is a bit more chaotic. Imagine a raging river, with water swirling and splashing all over the place. In turbulent flow, the fluid particles are constantly colliding and mixing, causing more resistance and making it harder to predict the flow’s behavior.

Learn more about laminar and turbulent flow from Wikipedia.

Now that we’ve covered the two main types of flow, let’s explore some factors that can affect pipe flow:

- Pipe diameter: The size of the pipe has a direct impact on the flow. A larger diameter generally leads to lower flow resistance and higher flow rates.

- Fluid viscosity: Viscosity is a measure of how thick a fluid is. The thicker (or more viscous) the fluid, the harder it is for it to flow through a pipe.

- Pipe roughness: The smoother a pipe’s interior surface, the less resistance there is for the fluid to flow. Rough pipes can lead to more turbulent flow and increased energy loss.

- Flow velocity: The speed at which the fluid is moving in the pipe affects the type of flow as well. Higher velocities are more likely to cause turbulent flow, while lower velocities favor laminar flow.

By understanding these basic concepts of pipe flow, you’ll be well-equipped to tackle any flow-related challenge!

Types of Pipe Flow Meters

By understanding different types of pipe flow meters, you’ll be well-prepared to choose the right one for your specific needs!

| Type of Flow Meter | Common Flow Meters | Description |

| Differential Pressure | Orifice plates | A thin plate with a hole in the middle placed inside the pipe; measures pressure drop to calculate flow rate. |

| Venturi tubes | A tube with a narrow, cone-like section that causes fluid to speed up and pressure to drop; measures pressure difference to calculate flow rate. | |

| Flow nozzles | A nozzle with an opening through which fluid passes; smooth shape reduces energy loss, suitable for high-velocity flows. | |

| Velocity Flow Meters | Turbine flow meters | A turbine inside the pipe that spins due to fluid flow; measures rotation to determine flow rate. |

| Vortex flow meters | Creates vortices in the fluid; measures the frequency of vortices to determine flow rate. | |

| Ultrasonic flow meters | Measures fluid’s velocity using sound waves without touching it. | |

| Magnetic flow meters | Measures flow rate of conductive fluids using a magnetic field. | |

| Positive Displacement | Piston flow meters | A chamber with a piston that moves due to fluid flow; counts piston movements to calculate flow rate. |

| Gear flow meters | Uses rotating gears to trap and measure fluid’s volume to determine flow rate. | |

| Diaphragm flow meters | Flexible diaphragm moves back and forth due to fluid flow; measures volume of fluid that passes through. | |

| Mass Flow Meters | Coriolis flow meters | Uses a vibrating tube to measure fluid’s mass flow; detects changes in vibration and converts data to flow rate. |

| Thermal mass flow meters | Heats up the fluid and measures heat loss to determine the mass flow rate of gases. |

Read more about: Different Types of Flowmeters – Technical and Application Analysis

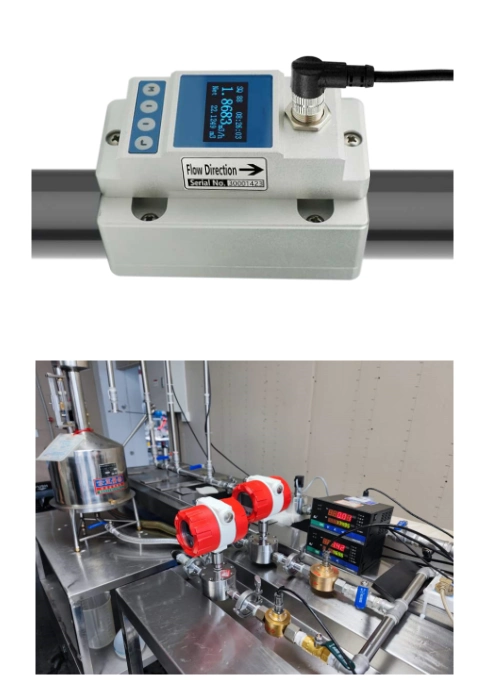

Featured Pipe Flow Meters

Shop 101: Key Factors in Selecting a Pipe Flow Meter

Choosing the perfect pipe flow meter can be a bit tricky, but if you keep these key factors in mind, you’ll be on the right track. Let’s break them down in a way that’s easy to understand.

Flow Range and Accuracy

- Pipe diameter and flow range: Like DN20, Diesel flow range 0.8~8m³/h;

- Accuracy requirements: The accuracy of conventional liquid flowmeters is 0.5%, and the accuracy of common gas flowmeters is ±1.0%. These can basically meet the needs of most users. If you have high precision requirements, be sure to let us know in advance.

- Pressure drop: Some flow meters cause a pressure drop in the system.

Fluid Compatibility

- Fluid type: Whether you’re measuring water, oil, or something else entirely. Make sure the flow meter is compatible with the type of fluid you’re working with.

- Fluid properties: Things like corrosiveness, abrasiveness, and conductivity can impact a flow meter’s performance. So choose one that can handle your fluid’s specific properties.

- Fluid viscosity: Viscosity affects how easily a fluid flows. Pick a flow meter that works well with the viscosity of your fluid.

- Temperature and pressure: such as 1.6Mpa, normal temperature. If there is a demand for high temperature or extremely low temperature, you also need to pay attention.

Installation and Maintenance

- Installation: Consider whether the flow meter can be installed without breaking the pipeline or if it requires a special installation process. Some flow meters, like clamp-on ultrasonic meters, are non-invasive and don’t require breaking the pipeline.

- Calibration: Check how often the flow meter needs to be calibrated and whether it can be easily calibrated in your system.

Budget

- Last but not least, think about your budget. While it’s important to find a flow meter that meets your needs, it’s also essential to choose one that fits your budget without compromising on quality or performance.

By considering these factors, you’ll be well on your way to selecting the perfect pipe flow meter for your specific needs!

Frequently

Asked

Questions

More Pipe Flow Measurement Solutions

3 inch (3″) Water Meter

2 inch Water Flow Meter

Digital Beer Flow Meters

Industrial CO2 flow meters

Cryogenic Flow Meters for Sale

Flow Pressure Transducers for Fluid Pipelines

In conclusion, selecting the right pipe flow meter is crucial for accurate and reliable flow measurements. Understanding the different types of flow meters, their principles, and the key factors to consider when choosing one will help you make an informed decision. Whether you need to measure volumetric flow, mass flow, or velocity flow, there’s a flow meter out there that suits your specific needs.

If you’re looking for a trustworthy source of pipe flow meters, look no further than Sino-Inst. As a professional pipe flow meter manufacturer and supplier, Sino-Inst has years of experience in providing high-quality, reliable, and cost-effective flow meter solutions. Our extensive range of flow meters ensures that you’ll find the perfect fit for your application.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.