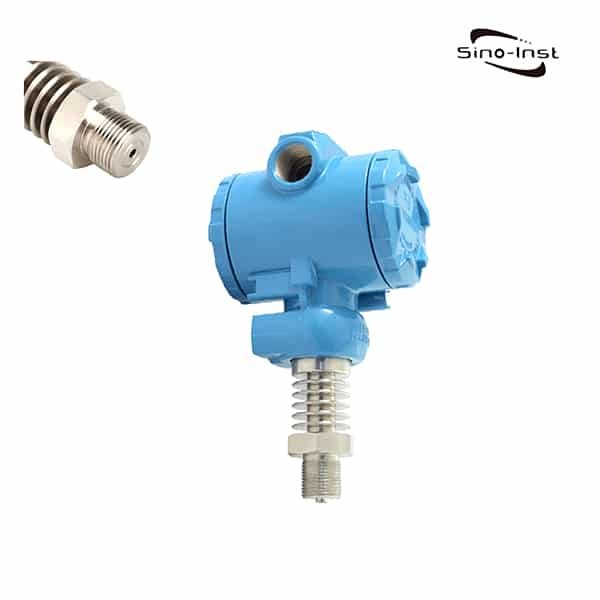

High Temperature Pressure Transducer is specially used for high temperature medium pressure measurement. Such as high temperature liquid, gas, steam, etc. The highest temperature is customized to 850℃.

High temperature resistant pressure sensor is selected as the signal measurement element. The transmitter structure includes a heat dissipation structure, and the high-precision signal processing circuit is located in the stainless steel housing. The sensor output signal is converted into a standard output signal, such as 4-20mA.

Sino-Inst is a manufacturer of high temperature pressure transducer in China. Committed to the manufacture, sales and engineering support of high temperature pressure sensors.

Features of SI-2088 High Temperature Pressure Transducer

- Working temperature –55 …850 ° C, customizable;

- Pressure range can also be customized, such as 150MPa high pressure;

- The sensor and pressure interface are fully welded structures, and the housing protection level is IP65;

- The material in contact with the medium is stainless steel, which has good corrosion resistance;

- It is suitable for pressure measurement of high temperature, low temperature and normal temperature media, and can work stably for a long time;

- It is impact-resistant, vibration-resistant and corrosion-resistant;

High temperature pressure transducer for measuring lowest pressure fluctuations in a harsh environment up to 850 ° C. For applications in hazardous areas, the sensor is available with intrinsically safe Ex-ia and non-incendive Ex-nA certifications.

Specifications of High Temperature Transducer

| Range: | 0 ~ 1KPa ~ 10KPa ~ 400KPa, -0.1 ~ 0 ~ 1 ~ 60 (MPa), 0 ~ 10KPa ~ 100MPa, Other pressure ranges can be customized. |

| Comprehensive accuracy: | 0.25% FS, 0.5% FS |

| Output signal: | 4-20mA (2/4-wire system), 0-5 / 1-5 / 0-10V (3-wire system) |

| Power supply voltage: | 24DCV (9 ~ 36DCV) |

| Medium temperature: | -30 ℃ ~ 160-350 ℃, customized up to 800 ℃. |

| Ambient temperature: | Normal temperature (-20 ~ 85 ℃) |

| Load resistance: | Current output type: maximum 800Ω; voltage output type: greater than 50KΩ |

| Insulation resistance: | Greater than 2000MΩ (100VDC) |

| Long-term stability: | 0.1% FS / year |

| Vibration effect: | In the mechanical vibration frequency 20Hz ~ 1000Hz, the output change is less than 0.1% FS |

| Electrical interface: | Hessman connector (customizable) |

| Thread connection: | M20 × 1.5, etc. Other threads can be designed according to customer requirements |

| Dimensions: | M20 × Φ26.5 × 156 |

| Shell protection: | Plug type (IP65); cable type (IP67) |

| Safety explosion-proof: | Ex iaⅡ CT5 |

Extended reading: High accuracy pressure transducers

Applications of high-temperature transmitters

SI2088 High Temperature Pressure Transducer used in the fields of steam, oil, boiler and heat energy exchange. Realize the measurement of liquid, gas and vapor pressure.

Application examples:

- Industrial field process pressure detection;

- Laboratory pressure calibration system;

- Navigation and Shipbuilding;

- Aviation and aircraft manufacturing;

- Air separation equipment and thermal power unit;

Application of high-temperature transmitter

Extended reading: Common Pressure Sensor Applications

Application of high temperature pressure transmitter in steam pipeline

Pure steam pipes have good mechanical properties and thermal insulation properties. Under normal circumstances, it can withstand a high temperature of 120 ° C. It can withstand a high temperature of 180 ° C by modification or in combination with other thermal insulation materials.

It is suitable for thermal insulation of various cold and hot water high and low temperature pipelines. The pressure detection in the steam pipeline is very important. And because of the high temperature characteristics in the pipeline. Therefore, it is suitable to use the high temperature pressure transmitter designed by our company for such occasions.

Extended Reading: MEMS Pressure Sensors

In addition, in the steam system, water hammer (Water Hammer) is one of the main hazards causing casualties. Thereby eliminating the hazard of water hammer. This shows that daily pressure monitoring of the pipeline is very important.

Extended reading: High Temperature Flow Meter

Precautions for the correct use of steam pressure transmitters

1. Prevent the steam pressure transmitter from contacting with corrosive or overheated media;

2. Prevent dross from depositing in the conduit;

3. When measuring gas pressure, the pressure port should be opened at the top of the pipeline, and the pressure transmitter should also be installed at the top of the pipeline, so that the accumulated liquid can be easily injected into the process pipeline;

4. The pressure guiding pipe should be installed in a place with small temperature fluctuation;

5. When measuring steam or other high-temperature media, a condenser such as a buffer tube (coil) should be connected, and the working temperature of the transmitter should not exceed the limit;

6. When freezing occurs in winter, the transmitter installed outdoors must take anti-freezing measures to avoid the expansion of the liquid in the pressure port due to the frozen volume, resulting in the loss of the sensor;

7. When wiring, pass the cable through the waterproof connector or the flexible tube and tighten the sealing nut to prevent the rainwater etc. from leaking into the transmitter housing through the cable.

High Temperature Pressure Transducers vs. Cooling Elements

Generally, the design method is to reduce the temperature near the pressure transmitter by incorporating mechanical cooling components to dissipate heat.

The cooling assembly may be filled with oil and isolated from the process medium by the isolation diaphragm.

Alternatively, the cooling assembly may include a hollow tube. The shape of the hollow tube is designed to increase heat transfer. This allows the process medium that is allowed to pass to be lowered to a much lower temperature.

The cooling element usually relies on the principle of convection heat transfer. This convective heat transfer principle is a mechanism for transferring heat due to the movement of fluid. In contrast, conductive heat transfer is the transfer of energy due to molecular vibration. In addition to cooling elements, convection is also used in many other engineering practices.

The cooling element may be able to reduce the temperature of the medium. This is usually a much cheaper solution than high temperature sensors. It is assumed that the medium density is not greatly affected by temperature changes within the normal operating range. Then this method can keep the pressure unchanged.

The cooling element usually works in air and water, but it is not suitable for oily media such as hydraulic oil. High temperature sensors must be used in these applications because the viscosity of this medium is highly temperature dependent.

The cooling element should be made of stainless steel so that most process media have maximum corrosion resistance. The nickel content of the steel is usually 1.25% and the chromium content is 0.65% to 0.8%.

The cooling element should withstand a maximum pressure of 5,000 psi at 38 ° C (100.4 ° F) and a maximum pressure of 3500 psi at 400 ° C (752 ° F). It also reduces the liquid process temperature at the sensing element from 260 to 38 ° C (500 to 100.4 ° F).

600 ℃ High Temperature Remote Pressure transmitter / Differential Pressure Transmitter

600 ℃ ultra-high temperature remote transmission pressure transmitter / remote transmission differential pressure transmitter cleverly uses the combination of ultra-high temperature silicone oil and internal isolation diaphragm. This makes the field application temperature greatly increased to about 600 ℃.

Greatly expanded the application range of ultra-high temperature pressure / differential pressure measurement. It can be widely used in coal chemical industry and CSP industry.

How to Select a Pressure Transducer For High Temperature Medium

Define your high temperature pressure transmitter requirements using this checklist:

- Process temperature?

- Cooling mechanism?

- Ambient temperature?

- Pressure range?

- Output signal? 4-20mA

- Electrical connection?

- Process connection?

- Process media type?

More Featured Pressure Transducers and Solutions

- How to Calibrate a Pressure Transmitter

- Differential Pressure Transmitter Installation Guide

- Use Differential Pressure Transmitter to Measure Liquid Level

- MEMS Pressure Sensors

- Application Analysis of Intelligent Pressure Transmitter

- Differential Pressure Flow Meters

- Water Pressure Transducers

- Capacitive pressure transducer

- Pressure indicator transmitters

- How Does a Pressure Transmitter Work?

- Pressure Transmitter Calibration

- SMART HART Pressure Transmitter

Sino-Inst produces and supplies pressure transmitters that meet various extreme temperature conditions. In addition to customizing high temperature pressure transmitters, we can also customize ultra-low temperature pressure transmitters, ultra-high pressure pressure transmitters, etc.

Our high temperature pressure transmitters are suitable for high temperature applications such as steam, food processing and engine monitoring. We widely serve users in various countries and industries.

If you have a special request, you can just contact us for Technical Support.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.