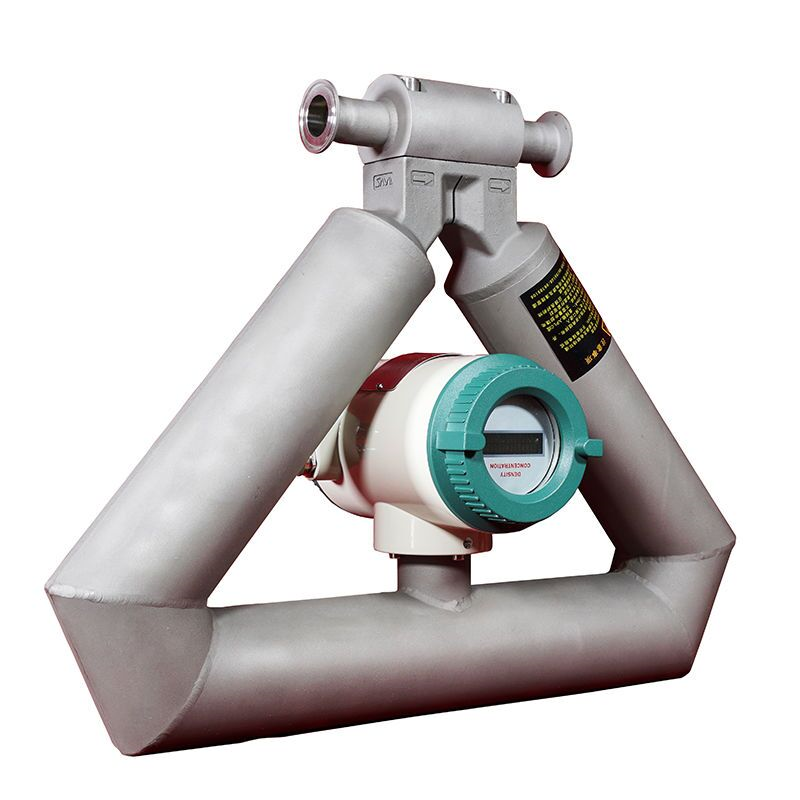

Coriolis Density Meter is also called Coriolis Concentration Meter. It adopts the principle of operating under the special law of the Coriolis force of the moving liquid. The Coriolis force is related to the density of the liquid, so the density value of the liquid is measured. The concentration is calculated from the density and temperature. The Coriolis principle has high stability, high precision, good long-term stability, and no drift caused by the sensor. Coriolis Density Meter is used in many industries like oil refining, sugar, paper, and chemical. It measures weak acid-base solutions in the wine, salt, and printing industries.

Features of Coriolis Density Meter

- The 4-wire transmitter with an integrated structure has no moving parts and is easy to maintain; the 4-wire transmitter has 4-20mA output;

- Real-time display of five-digit density value, four-digit decimal (one digit for concentration), real-time indication of current and temperature;

- You can directly enter the instrument menu to set parameters;

- It is easy to install and use, and the reading can be displayed when the flange surface touches the liquid;

- It is used for fluid or static liquid, suitable for pipeline installation or installation on container wall, etc.;

- Density and concentration have the functions of pure water calibration, fine-tuning of measured value and temperature compensation;

- Continuous online measurement without process interruption, can be directly used for production process control;

- All parts in contact with liquid are made of 316 stainless steel or polytetrafluoroethylene, which is safe, hygienic and has good corrosion resistance;

- Measuring high viscosity and non-Newtonian flow can also measure uniform multiphase flow;

Technical Parameters

| Accuracy | ±0.001g/cc | ±1.0kg/m3 | |

| The scope of work | 0~3g/cc | 0~3000kg/m3 | 0~187.4 lb/ft3 |

| Repeatability | ±0.001g/c | ±0.1kg/m3 | ±0.006lb/ft3 |

| Process temperature effect (corrected) | ±0.001%g/cc) | ±0.1kg/m3 | (per °C) |

| Process pressure effect (corrected) | can be ignored | ||

| (1) The above accuracy is applicable to the calibration range of 0.6-1.25g/cc (600-1250kg/m3) (2) When a long rod is used, the maximum viscosity of the liquid can reach 500CP, but if it is used, the maximum viscosity of the liquid can reach 20000CP. (3) Temperature effect refers to the maximum measurement deviation caused by the process fluid temperature deviating from the factory calibration temperature. (4) Pressure effect is defined as: the change in sensor flow and density due to process pressure deviation from calibration pressure. | |||

| Process temperature | –10℃~+60℃ |

| Ambient temperature | –10℃~+85℃ |

| Temperature Coefficient | O.1kg/m3/℃ (after correction) |

| Built-in temperature sensor | PT100 |

| Wetted parts | Stainless steel 316L, titanium, etc. can be customized |

| Shell | IP65, aluminum alloy |

| Tine polishing | Standard, PFA coated or electropolished |

| Working pressure | 3000psi (207bar) |

| 1450psi (100bar) | |

| Test pressure | Tested at 1.5 times the maximum working pressure |

| Actual maximum working pressure is limited by process connection rating | |

| Process connection type | flange |

| Clamp | |

| thread | |

| Explosion-proof certification | Ex d Ⅱ B T6 Gb |

| Power requirements | 24VDC,50mA |

| Output | Four-wire system, 4-20mA transmission 4-20mA, optional RS485-Modbus RTU communication |

| Viscosity range | 0-20000CP |

Fluid and Material Compatibility

| Type | Name | Molecular formula | Concentration (%) | 316L | Hastelloy | Titanium alloy | zirconium | PTFE |

| Acid | Hydrochloric acid (without hydrofluoric acid) | HCI | 0-40 | × | ○ | × | ☆ | ☆ |

| sulfuric acid | H2SO4 | 0-50 | ○ | ☆ | ○ | ☆ | ☆ | |

| H2SO4 | 50-75 | × | ○ | × | ○ | ☆ | ||

| H2SO4 | 75-98 | ○ | ☆ | ○ | ○ | ☆ | ||

| nitric acid | HNO3 | 0-100 | ○ | ○ | ○ | ○ | ☆ | |

| phosphoric acid | H3PO4 | 0-98 | × | × | × | × | ☆ | |

| Alkali | sodium hydroxide | NaOH | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ |

| Potassium hydroxide | KOH | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ | |

| Calcium hydroxide | Ca(OH)2 | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ | |

| Salt | Sodium chloride | NaCI | 0-50 | × | ☆ | ☆ | ☆ | ☆ |

| ammonium chloride | NH4CI | 0-50 | × | ☆ | ☆ | ☆ | ☆ | |

| ammonium sulfate | (NH4)2SO4 | 0-50 | × | ☆ | ☆ | ☆ | ☆ | |

| Others | carbamide | (NH2)2CO | 0-100 | ☆ | ☆ | ○ | ☆ | ☆ |

| sodium hypochlorite | NaOCI | 0-16 | × | ○ | × | ☆ | ☆ | |

| hydrogen peroxide | H2O2 | 0-90 | ☆ | ☆ | ○ | ☆ | ☆ | |

| ☆Recommended ○ Use under specific concentration and temperature limits × Do not use | ||||||||

Featured Types of Coriolis Density Meters-Concentration Meters

Coriolis density meter industrial applications

The Coriolis density meter is based on the principle of special laws under the action of the Coriolis force of the moving liquid. The Coriolis force is related to the density of the liquid, so as to measure the density of the liquid; then according to the relationship between density and concentration The relational table obtains concentration values at a temperature of 20°C.

Coriolis density meter can be widely used in the detection of oil refining and blending in the petrochemical industry. The food industry is used in sugar industry, vegetable oil and beverage processing, etc. Production site, paper industry, measurement of weak acid-base solution in chemical industry, wine industry, salt, printing and dyeing and other industries. Due to the large flow pipe, it is especially suitable for occasions that are not dry or viscous. It is suitable for pipe installation.

| Medium limitation | Contain gas | Maximum Liquid Viscosity | |

| Regular liquid | Acid and alkali solution | ||

| 316L | Titanium | Contain gas Generally do not use | 20000CP |

Typical application conditions:

| Petroleum and petrochemical industry | — Quality Control — Continuous Online |

| Wine industry | — Quality control — Continuous online inspection |

| Organic and Inorganic Chemical Materials | — Acid/base concentration control |

| Pharmaceutical Industry | — Traditional Chinese medicine concentration, alcohol recovery |

| Battery industry | — Concentration of lithium hydroxide, electrolyte, sulfuric acid solution |

| Mineral processing | — Clays, carbonates, silicates |

More Density meter and measurement analysis solution

What Is Density Meter? and Types

Ultrasonic Level Transmitter Installation Guide

What Is the Ultrasonic CO2 Level Indicator? CO2 Bottle Level Measuring Device

Dew Point Monitor for the Fruit and Vegetable Industry

Radar Level Gauge – Everything You Should Know and Selection List

Oxygen Cleaning Pressure Sensor – No Oil, No Corrosion, No Impurities

Coriolis mass flowmeter is a kind of instrument that is commonly used at present and has relatively high stability and reliability of measurement accuracy. Coriolis mass flow meters are not only capable of measuring mass flow meters from Micro Motion, but also of media density.

When the Coriolis Density Meter measures density, its measuring tube vibrates continuously at a certain resonant frequency. Because the resonance frequency is a function of the fluid density. When fluids of different densities fill the vibrating tube, its vibration frequency will also change. Therefore, measuring the frequency change of the vibrating tube completes the density measurement. The linear relationship between the density and the vibration frequency of the vibrating tube.

This method is accurate and reliable in measurement, and is suitable for a wide measurement range of various fluid densities. The pressure loss of Coriolis Density Meter is very small, and it has inherent advantages in measuring the density of viscous fluids such as mud.

There are more and more requirements for density measurement in the current production process, and the accuracy of density measurement directly affects the quality of production process.

We Sino-Inst manufacture and supply many kinds of Coriolis Density Meters-Concentration Meters. Our Coriolis Density Meters are exported to various countries like USA, UK, Germany, Nigeria, Saudi Arabia, Singapore, etc. If you need to measure density, please feel free to contact our sales engineers.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.