Cable Float Level Sensor (Float level switch) for water/level switch control.

Cable Float Level Sensor (Float level switch) is a high performance level control switch. It can control the work of the liquid pump, adjusting the liquid level. And it can also be installed in the submersible pump to control and protect the motor. High sealing performance is guaranteed by polypropylene injection. It is a switch that can adjust the liquid level in a bucket, tank or well. Cable Float Level Sensor is self-adjusting, easy to operate, easy to install and maintenance-free. It has a resistance to sewage. It is used in mines, oil, irrigation containers, etc.

Please feel free to contact us for Techinical Support, or Request a quote for float level sensors (customization available).

The Cable Float Level Switch is designed using the principles of gravity and buoyancy. Cable Float Level Sensor has a simple and reasonable structure. Including: A floating body. A large-capacity miniature switch set in the floating body.

A driving mechanism capable of turning the switch on and off. And a three-core cable connected to the switch. The outstanding feature of this product is its stable and reliable performance. Cable Float Level Sensor has no malfunction caused by the fluctuation of the liquid surface.

At the same time, it has the characteristics of convenient installation, low price and long service life. This product can be used with various liquid pumps, and automatic control of water levels in water supply, drainage and rotten liquids.

Features of SI-U05 Cable Float Level Sensor

Cable Float Level Sensor can be matched with various liquid pumps. And is widely used for automatic control of water levels in water supply, drainage and corrosive liquids.

- Simple construction.

- Reliable performance. The product can send switch control signals under normal conditions. Strong reliability.

- Durable and long life.

- Easy installation method. Convenient adjustment method. Adjustable water level control range.

- Simple circuit. Economical and practical operating voltage 220v. Current 10A. Simple circuit and low cost.

- Resistant to corrosion.

Specifications of SI-U05 Cable Float Level Sensor

| Float Materia: | PP, SUS304 |

| Contact Capacitance: | 10A/250VAC(PP),2A/250VAC(SUS304) |

| Contact type: | 1A,1B or 1AB(PP),SPDT(SUS304) |

| Cable specification: | Rubber cable and PVC(PP),Silicone:0.75mm2×3C(SUS304) |

| Suitable temperature: | Rubber cable: -10℃~80℃,PVC cable:0℃~60℃,Silicone: 0~170℃ |

| Gravity: | >0.6g/cm3(PP),>0.5g/cm3(SUS304) |

| Lead length: | 2m 3m 4m 5m 10m, etc. Other lengths can be customized |

| Applicable medium: | Clean water, sewage, oils and acid-base liquids below medium concentration |

Applicaitons of Cable Float Level Sensor & Swtich

- Water level monitoring

- Tank level control

- High or low level alarm

- Municipal water control

- Industrial water control

- Filling or draining reservoirs and tanks

- Pump automation

- General pump control

- Pump control in wastewater

- Suitable for low specific gravity materials

- Can handle high operating temperatures

- Clean fluids with small process connections

- Water and wastewater

- Petrochemical

- Chemical

Extended reading: Ultrasonic Level Switch-External Mounted

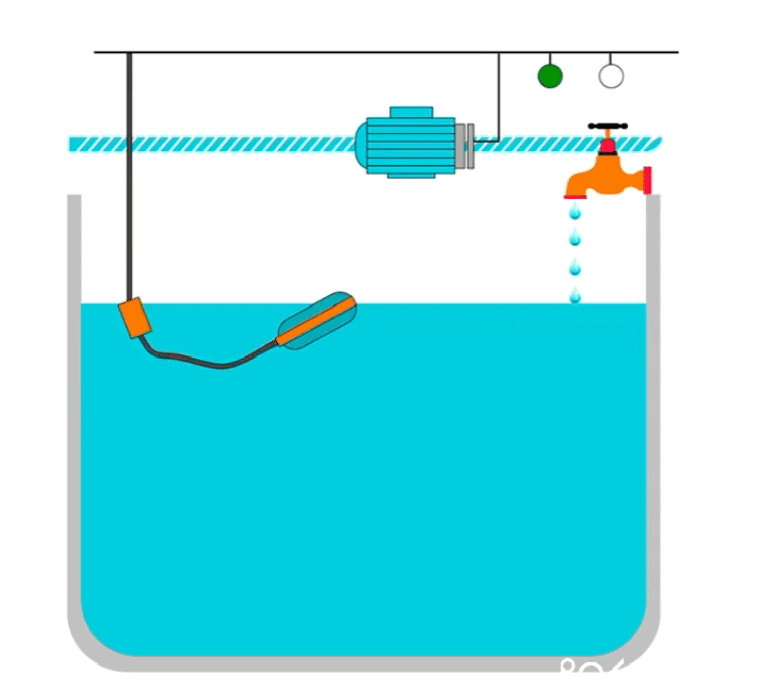

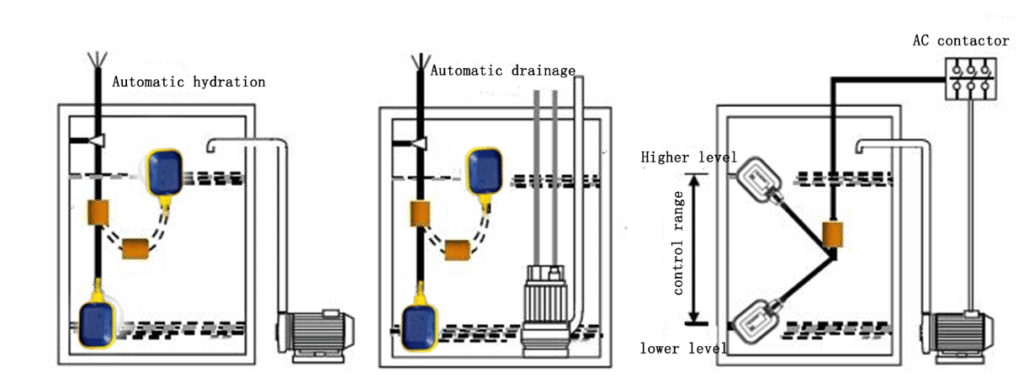

Working Principle of Float Level Sensor

The Cable Float Level Switch is with simple structure of using micro switch or proximity switch or reed switch to control the contact. And it is user friendly design for level measurement. The switches will send out ON or OFF contact signal output. The floating angle is larger than a certain degree. Then the state of the iron ball and reed switch will be changed for actuation. For wastewater and applications at different temperatures, the material of the float can be selected from plastic to stainless steel. Cable float level switch controls long distance and multi-point contact detection. Cable float level switch can be used for transparent liquid and granular liquid industries.

Float Level Sensor Installation

- Pass the wire of the float switch from the concave circle of the center of the weight. Push the weight gently to make the plastic ring embedded above the round hole fall off due to the thrust of the wire head. You can also use a screwdriver to remove this plastic ring. Then put the dropped plastic ring on the cable to set the water level by the weight you want.

- Gently push the weight to pull out the cable until the center of the weight holds the plastic ring. As long as the heavy hammer is lightly buckled in the plastic ring, it will not slip. If the plastic ring is damaged or lost, it can be replaced with a light bare copper wire into the cable.

- Please pull the cable directly to the control box. Avoid using the intermediate connector as much as possible. If there is a connector as a last resort, never immerse the cable connector in the water.

Other types of Float Level Switches

Liquid level float switch is a commonly used liquid level controller. For water Tank & Pump alarm and level control. Can be divided into Continuous Float Level Sensor and Point Level Float Switch. Read more about Guide for Liquid level float switches.

Q&A

The float level switch is based on the principle of buoyancy. The float ball moves a distance with the liquid surface, and this movement plays a limit role. A magnetic floating ball is used to generate a switching action with a reed switch, output a switching signal, and then control the liquid level through wiring.

The float level switch only needs to re-calibrate the water level line before we install it. The switch itself cannot be adjusted. At this time, use a multimeter to measure the switch state, and it will be turned on and off with the water level near the waterline, which means that there is no problem. Just make sure that the water level line of the thermal equipment is consistent during the installation. For example, the liquid level switch of SOR is generally attached to the water level line on the wall of the cylinder. We soak the switch in the water tank and slowly sink, so that the water surface gradually approaches the marking line. When it is closest, we will hear the micro switch action the sound of.

It should be noted that the working temperature of the high-level liquid level switch is high, and the water temperature inside is also high; the density of high-temperature water is less than that of room temperature water. Therefore, the action line of room temperature water is lower than the switch identification line.

Low level alarm is connected to normally closed (NC), high level is connected to normally open (NO). This type of switch is not difficult to install. The liquid level switch itself will have more than two pairs of micro-switches, which respectively output two pairs of normally open and two pairs of normally closed contacts, which are usually “on alarm” when applied.

The liquid level sensor converts the liquid level signal in the container into a switching signal or a voltage and current signal, and then through an external circuit, allows the surveyor to accurately know the liquid level in the container.

There are 7 main types of level transmitters that Sino-Instrument offers. Each type of transmitter works in a different way, and makes it useful for different types of processes.

Liquid level switch, also known as water level switch, liquid level sensor. The liquid level switch is a switch used to control the liquid level. It is mainly divided into contact type and non-contact type. Capacitive liquid level switches are commonly used in non-contact switches. And contact float type liquid level switches are most widely used. Electrode level switches, electronic level switches, and capacitive level switches can also be implemented using contact methods.

There are currently 6 medium level switches:

- Float level switch: The magnetic float of the float level switch rises or falls with the liquid level. So that the sensor detects the position of the reed switch chip in the tube, and sends a contact on / off switch signal. Because of its simple structure and economic benefits, it is widely used in the market, mainly for civilian use. But its stability is relatively poor compared to industrial-grade products.

- Capacitive liquid level switch: After the probe is wetted, it detects the change in capacitance value and outputs a contact signal, which has certain advantages in the measurement of slightly viscous media.

- Electrode type liquid level switch: The electrode type liquid level switch uses the conductivity of the liquid to detect the level of the liquid. Once the measured medium touches the pole, it will conduct electricity and detect the signal. After the signal of the controller is amplified, a contact signal is output to realize the control of the liquid level.

- The photoelectric liquid level switch: The photoelectric liquid level switch uses infrared detection, using the principle of refraction and reflection of light. The reflection or refraction of light at the interface between two different media. When the measured liquid is at a high level, the measured liquid forms a kind of interface with the photoelectric switch. When the measured liquid is at a low position, air and the photoelectric switch form another interface. These two interfaces make the intensity of the reflected light received by the light receiving crystal inside the photoelectric switch different. That is, correspond to two different switching states. Generally speaking, compared with other measuring instruments, the applicability of photoelectric switches is poor.

- Tuning Fork Liquid Level Switch: It outputs a switch signal by detecting the change in the frequency and amplitude of the fork’s vibration, which is highly versatile. For the viscous working conditions, please consult with the manufacturer to determine the working conditions that are easy to crystallize.

- Ultrasonic external liquid level switch: The instrument probe emits ultrasonic waves and detects its residual vibration signal in the container wall. When liquid passes through the probe, the amplitude of this aftershock signal becomes smaller. This change is detected by the meter and outputs a switching signal. It is a non-contact type and is often used in high-risk situations where it is difficult to open holes on the site, but the cost is relatively expensive.

Techinical Support

Sino-Inst is float level sensor manufacturer. On the premise of ensuring product quality, we offer you the best price.

Sino-Instrument offers over 10 level transmitters for level measurement.

About 50% of these are liquid level meters,

40% is the tank level sensor.

A wide variety of level meters options are available to you,

such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.