Holding tank level indicators can help us monitor and control liquid levels. Whether it is a fuel tank on a truck, a fire water storage tank, an underground sewage storage tank, or even a marine storage tank, etc. Replacing manual inspection with automated Level Monitoring System can be faster and more accurate.

Disassemble the system

Before setting up a Level Monitoring System for Industrial Holding Tanks, we need to first understand what should be included in the system.

Based on our many years of experience in level monitoring services at Sino-Inst, we have simplified the entire system from complexity. Simply put, the system can be divided into two parts: Level sensor + Tank level Monitor.

These two parts are both independent and interrelated. You can choose different types of level sensors and Tank level Monitors according to actual needs. Then use the connection key, which is our signal output (such as RS485, 4-20mA) to make them work synchronously.

Exploring Advanced Level Monitoring Technologies

Part 1: Level Sensor

We have analyzed the working principles, advantages and disadvantages of various level sensors in detail in our previous blog. You can learn more about it. Here, we briefly introduce a few commonly used ones:

- External ultrasonic level sensor: It can be simply pasted on the bottom of the tank for liquid level measurement. Suitable for tanks less than 2 meters. Like a truck fuel tank.

- Capacitive level sensor: suitable for liquid level measurement under various special conditions such as high pressure, high temperature, extremely low temperature, etc.

- Ultrasonic level sensor: low-cost non-contact measurement. You can choose anti-corrosion and explosion-proof materials.

- Radar level sensor: wider application range. High measurement accuracy. Can be applied to tanks with a measuring range of 30m.

- Magnetostrictive level sensor: the most accurate level sensor. Can be customized as an oil level interface sensor. It can also be customized to measure temperature at the same time.

- Hydrostatic pressure level sensor: enables low-cost, large-range measurement.

- Float level sensor: The measurement principle is the simplest.

Part 2: Monitor System

We generally configure paperless liquid level recorders for users to measure and record on-site liquid level signals. It can even perform alarm, signal output, printing and other functions according to user needs.

For example, some of our common models:

7620/7620R Series LCD Volume Display Regulator/ Recorder is specifically designed for industrial on-site regular and irregular canned liquid, volume and mass conversion.

The device has empowered by the surface mounting technology, featuring the design of multiple-layered protection and isolation, with a strong anti-interference capability and high reliability. It has used the embedded operating system with USB data dump function. The data storage time could reach up to 720 days. By using U disk and host computer analysis software, one could call and view the historic curve of process variants and relevant historic data from time to time. It also could match with various liquid sensors, such as ultrasonic liquid level meter. The device has sound anti-theft and anti-damage and other features.

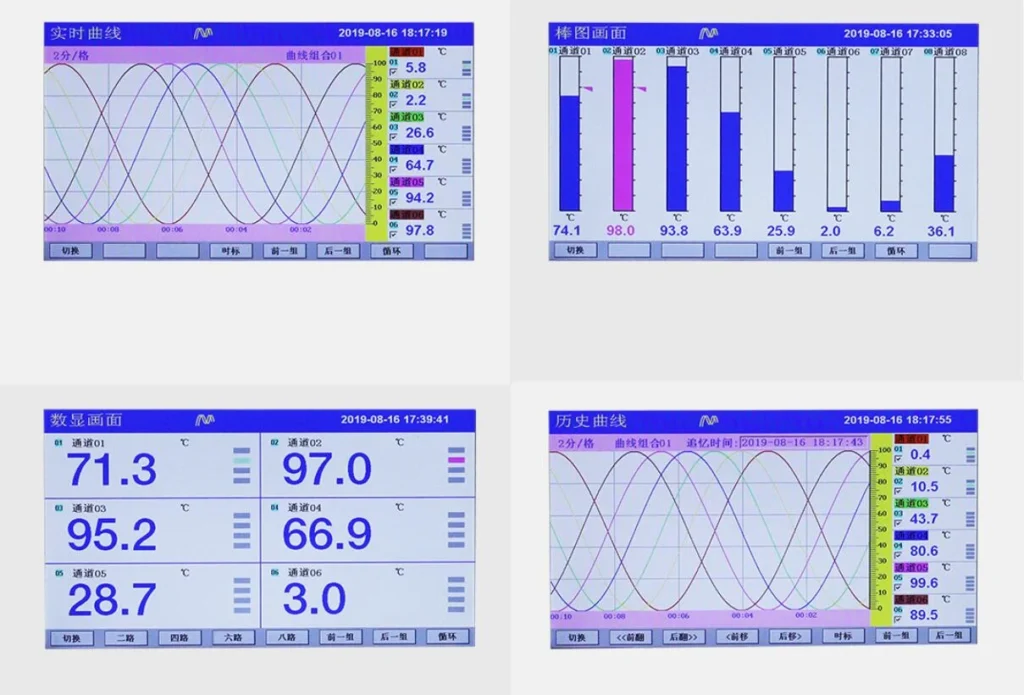

T710 series paperless recorder adopts the new large-scale integrated circuits to realize the reliable protection and robust anti-jamming for input, output, power supply and signals. The recorder can achieve eight-channel universal signal input (the configurable and optional inputs include standard voltage, standard current, thermocouple, thermal resistance and millivolt), four-channel alarm output and one feed output. It has the RS485 communication port, Ethernet port, micro-printer port, USB device port and SD card socket. The recorder enjoys a Powerful display function, which can achieve real-time graphic display, historical graphic recalling, bar graph display and alarm status display.

Universal input of NHR-8100/8700 series color paperless recorder (capable of inputting by means of configuration: standard voltage, standard current, thermocouple, thermal resistance, millivolt, etc.). It can be equipped with 18-channel alarm output or 12 -channel analog transmitting output, RS232/485 communication interface, Ethernet interface, mini-printer interface, USB interface and SD card socket; can provide sensor distribution; is equipped with powerful display function, real-time curve display, historical curve retrospection, bar graph display, alarm list display, etc. The meter is of high cost effectiveness due to its humanized design, perfect function, reliable hardware quality and exquisite craftsmanship.

Other requirements support customization.

Part 3: Featured Products

Steps to quickly build an industrial holding tank level indicator

Let’s say you only have the tank now. There is no liquid level sensor or system.

Understand the basic parameters of the tank. For example, the shape, height, width, wall thickness, pressure, and temperature of the tank. Is there stirring inside the tank?

If you already have a holding tank level sensor, just select the applicable level monitors based on the output signals supported by the level sensor.

More Level Measurement Solutions

- How to check Level in Underground Tanks? What Tank Level Indicators to Choose?

- Enhancing Marine Tank Monitoring with Advanced Marine Water Tank Level Sensors

- Shopping the Right High Temperature Level Sensor: 80℃~1000℃

- Cooling Tower Level Sensors for Water Level Monitoring and Water Level Control

- What Is the Ultrasonic CO2 Level Indicator? CO2 Bottle Level Measuring Device

- Ultrasonic Tank Level Sensors for Tank Level Monitoring

- Submersible Pressure Transducers 101: Guide to Precise Level Measurements

- Reliable Industrial Tank Level Monitoring System

- Ultrasonic Depth Sensor vs Ultrasonic Level Sensor

- How to Choose Explosion Proof Ultrasonic Level Sensor?

- How to Measure River Water Level?

- New Choice for Heating Oil Tank Level Sensor

- What Is Capacitive Level Sensor?

- Ship Ballast Tank Pressure-Liquid Level Measurement

- Cryogenic Level Sensor for Liquid Nitrogen Tank Level Indicator

- Liquid Volume Sensor? Monitors Liquid Volume Solutions

- Wastewater Level Sensor for Septic Tank-Sewage Holding Tank

- Water Level Monitoring Sensor/System for Sewage-Wastewater

- Water Tank Level Sensors for Level Monitoring & Control System

- Oil-water Interface Level Measurement Guide

- Use Differential Pressure Transmitter to Measure Liquid Level

- Guide to Ultrasonic Level Transmitters-for Continuous Non Contact Level Measurement of Liquid & Solids.

We at Sino-Inst are professional suppliers of holding tank level indicators. Our level sensors and level monitoring systems are widely used in various industries. For example, it can be used as sewage holding tank level indicator or marine holding tank level indicator.

In addition to supplying holding tank level indicators for tanks, we also provide pressure and temperature measurement solutions for various tanks. Including measurements under extreme conditions such as explosion-proof, anti-corrosion, high temperature, extremely low temperature, etc. There are also flow meters that can be used to monitor the flow of tank media filling pipes.

If you need to configure holding tank level indicators or other holding tank detection instruments, please feel free to contact our sales engineers!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.