Electronic flow meters are industrial digital flow meters for fluid flow rate measurement. In more cases, people will default that Electronic flow meters are electromagnetic flowmeters.

Electronic flow meters types like Magnetic, Vortex, and Ultrasonic flow meters. Electronic flow meters are suitable for Industrial liquid, water, natural gas, petrol, fuel, air, and more fluid flow. Electronic flow meters convert the monitored fluid flow into electronic signals. Including pulse signal, 4-20mA standard signal, etc.

Sino-Inst offers a variety of Electronic flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Sino-Inst, the manufacturer of Electronic flow meters. We will answer your various questions about Electronic flow meters.

What is electronic flow meter?

A flow meter is a device used to measure the volume or mass of a gas or liquid. Flow meters are referred to by many names, such as flow gauge, flow indicator, liquid meter, flow rate sensor, flow rate meter, etc. depending on the particular industry.

Electronic flow meters are industrial digital flow meters for fluid flow rate measurement. Electronic flowmeters types like Magnetic, Vortex, and Ultrasonic flow meters.

While magnetic, vortex, and ultrasonic–are neither exclusively nor exhaustively electronic in nature. They do represent a logical grouping of flow measurement technologies.

All electronic flow meters have no moving parts, are non-intrusive, and are made by electronics technology.

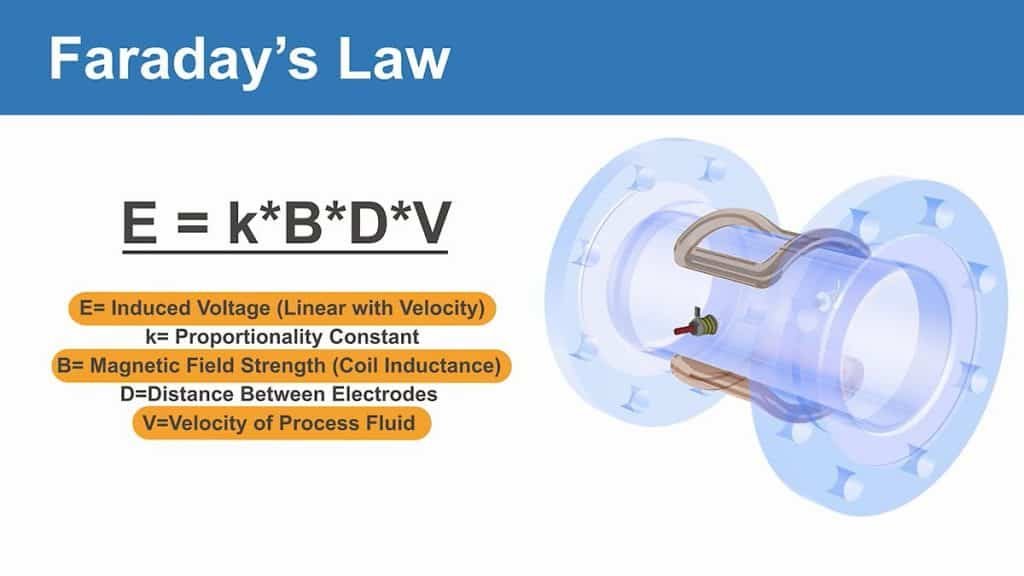

Magnetic flowmeters are the most directly electrical in nature, deriving their first principles of operation from Faraday’s law. Vortex meters depend on piezoelectric sensors to detect vortices shed from a stationary shedder bar. And today’s ultrasonic flowmeters owe their successful application to sophisticated digital signal processing.

Read more about: What is a Flow Meter? Types and how does it work?

Featured Electronic Flow Meters

Electronic flow meter working principle

Simply put, the working principle of Electronic Flow Meters is to convert the flow rate of the measured fluid into an electronic signal through the flow sensor component. And can carry out flow rate display and signal output. For example, display instantaneous flow rate, cumulative flow, etc.

As you can see. There are many types of Electronic Flow Meters. Therefore, their accurate measurement principles are different.

Perhaps you are not clear about the principle of Electronic Flow Meters. Don’t want to know more about it. Just want to find the applicable Electronic Flow Meters. Then you can start from your measuring medium.

Electronic flow meter for water

A Digital Water flow meter is a flow meter that can display the water flow rate, and have the output for the flow rate. Like 4-20mA output, HART, RS 485, and so on. Digital Water Flow Meter is also called Electronic Water Flow Meter. Digital Water Flow Meter is widely used in industrial water and household water measurement. Most of the Sino-Inst flow meters are digital water flow meters. Like the electromagnetic flowmeter, Portable ultrasonic flow meter, Turbine flow meter…..

Read more Digital Water Flow Meters

Electronic flow meter for air

Digital gas flow meters are flow meters used to monitor the gas flow rate or mass. Digital gas flow meters are designed to measure different types of gases. Like Air, N2, O2, CO2, and more.

Digital gas flow meters can measure the flow of a wide variety of gases. According to measurement principles, there can be positive displacement gas flow meters, velocity gas flow meters, and mass gas flow meters. How to choose the right Digital gas flow meters? We will discuss in detail next.

Read more Digital gas flow meters for Sale

Electronic flow meter for oil

Industrial oil flow meters measure the volume or mass of oil. Can realize the mutual conversion of volume and mass.

The main industrial oils are hydraulic oil. Gear Oil. Turbine oil. Compressor oil. Refrigeration oil. Transformer oil. Cylinder oil, heat treatment oil, heat transfer oil, etc. Of course, edible oil can also be produced in the industry. In addition, there are greases with lubricating oil as base oil and thickening agent.

Therefore, whether it is a company that uses, trades, or produces oil, it needs to accurately measure the oil flow.

There are many common oil flow meters, such as turbine flow meters, positive displacement flow meters, gear flow meters, mass flow meters, etc.

Then, we need to choose a suitable flow meter that meets the measurement and budget according to different working conditions.

Read more Industrial Oil Flow Meters

What are the different types of flow meters?

Flowmeter types: Generally speaking, we will classify flow meters according to their working principles.

Flow Metering Principals

- Differential Pressure Flowmeters

- Velocity Flowmeters

- Positive Displacement Flowmeters

- Mass Flowmeters

- For Open Channel Flowmeters – weirs, flumes, submerged orifices, current meters, acoustic flow meters and more

For different working principles, We offer different types of flow meters, like:

- Differential Pressure Flow Meters

- Orifice Plate

- Venturi Tube

- Flow Nozzles

- The Sonic Nozzle – Critical (Choked) Flow Nozzle

- Calorimetric Flowmeter

- Ultrasonic Doppler Flowmeter

- Positive Displacement Flowmeter

- Variable Area Flowmeter or Rotameter

- Velocity Flowmeters

- Pitot Tubes

- Electromagnetic Flowmeter

- Turbine Flowmeter

- Vortex Flow Meter

- Thermal Flowmeter

- Coriolis Flowmeter

- Mass Flowmeters

- Open Channel Flowmeters

Extended reading: Gas Rotameter Tips

How to choose your flowmeters?

Important factors when selecting flow metering devices are:

- Measured medium

- Accuracy

- Cost

- Flow rate range

- Pperating requirements

- Maintenance

- Lifetime

- Lead time

These factors are more or less related to each other. For example – the cost of flow meters increases with accuracy and lifetime quality. Read more about: What Is GPM In Flow Meter?

More about Electronic Flow Measurement Technology

- Flow Measurement Units-What Is GPM in Flow Meter?

- What Is a BTU Meter?

- Flow Rate and Pressure Relationship-How to Calculate?

- Water Flow Measurement for Pipes and Open Channels

- Industrial Helium Flow Meters

- 6″ Flow Meters List | 6 Inch- DN150 Connection

- What Is Vortex Flow Meter? and FAQs

- Guide to Pulse Flow Meters: Must Know Before Shopping!

- What Is Turbine Flow Meter? and FAQs

- What Is a Thermal Mass Flow Meter?

Sino-Inst offers over 50 Electronic flow meters for flow measurement. About 50% of these are differential pressure flow meters, 40% is the liquid flow sensor, and 20% are Ultrasonic Level Transmitter and mass flow meters.

A wide variety of Electronic flow meters options are available to you, such as free samples, paid samples. Sino-Inst is a globally recognized supplier and manufacturer of flow measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.