What is volumetric flow meter?

A volumetric flow meter is an instrument that can measure the volume of fluid passing through the measurement location within a set period of time.

A positive displacement flowmeter as a mechanical flow meter is a common type of Volumetric Flow Meter. It can measure the volume flow of high viscosity and corrosive fluids.

Sino-Inst offers a variety of Oval Gear Flow Meters for flow measurement. If you have any questions, please contact our sales engineers.

Featured Volumetric Flow Meters

Guess you like: What is Reynolds number?

Extended reading:

What is the K-factor in a flow meter?

Cryogenic Flow Meters|Liquid Nitrogen-Liquid Oxygen-LNG fluids

Volumetric flow meter working principle

The positive displacement flow meter is a flow meter that uses mechanical measuring elements to continuously divide the fluid into a single known volume, and repeatedly fill and discharge the volume of fluid to accumulate the total amount of fluid.

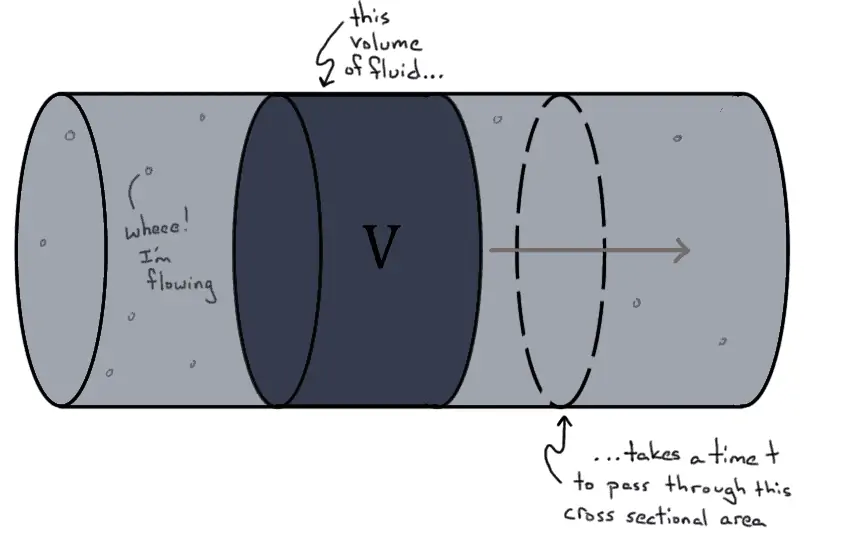

Volumetric flow measurement uses a fixed small volume to repeatedly measure the volume of fluid passing through the flowmeter.

Therefore, there must be a standard volume of space inside the positive displacement flowmeter, which is usually called the “metering space” or “metering chamber” of the positive displacement flowmeter.

This space is formed by the inner wall of the instrument case and the rotating parts of the flowmeter.

The working principle of a positive displacement flow meter is: fluid passing through the flow meter will produce a certain pressure difference between the inlet and outlet of the flow meter.

The rotating part of the flowmeter (referred to as the rotor) rotates under the action of this pressure difference, and discharges the fluid from the inlet to the outlet.

In this process, the fluid fills the “metering space” of the flowmeter again and again, and then is continuously sent to the outlet.

Under the conditions of a given flow meter, the volume of the metering space is determined. As long as the number of rotations of the rotor is measured, the cumulative value of the volume of fluid passing through the flow meter can be obtained. Flow rate of viscous fluids such as oils, condensate, resin and liquid food.

For the flow of high-viscosity media, other flowmeters are difficult to measure, but positive displacement flowmeters can accurately measure with an accuracy of ±0.2%.

Read more about: Large-diameter Oval Gear-Marine Fuel Flow Meter

Positive Displacement Flow meter Technology

How to convert Mass Flow Rate & Volumetric Flow Rate

- If the mass flow of the flow is known and needs to be converted into volume flow, the following formula can be used: qv=qm/ρ. In the formula, qv is volume flow, m3/s. qm is mass flow, kg/s. ρ is fluid Density, kg/m3.

- If the volume flow rate of the fluid is known, it needs to be converted into a mass flow rate, which can be done with the formula: qm=qv×ρ.

We provide you with some calculation tools for Mass Flow Rate & Volumetric Flow Rate conversion:

More: Mass Flow Rate vs Volumetric Flow Rate

More Featured Liquid and Gas Flow Meters

Frequently

Asked

Questions

Read more about: Flow Meter Selection Guide

Liquid and Gas Flow Measurement Solutions

Sino-Inst, Manufacuturer for Volumetric Flow Meters. For example: crude oil flowmeter, diesel flowmeter, gasoline flowmeter.

Sino-Inst’s Volumetric Flow Meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

What is Volumetric Flow Meter? How it works? Vs Mass Flow

A volumetric flow meter is an instrument that can measure the volume of fluid passing through the measurement location within a set period of time.

Product SKU: Volumetric Flow Meters

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 500

Price Valid Until: 2059-09-30

Product In-Stock: PreOrder

5