What is an Ultrasonic level transmitter?

Ultrasonic Level Transmitters & Ultrasonic Level Sensors are designed to provide accurate and reliable level sensing for difficult to monitor fluids, where contact with media is not desirable from the extremes of sending: ultrapure to corrosive or even dirty where coating or scaling is possible. Ultrasonic level transmitters have no moving parts, are easy to install and simple to use.

Ultrasonic level measurement provides continuous, non-contact and maintenance-free level measurement of fluids, pastes, sludges and powdery to coarse bulk materials. The measurement is unaffected by dielectric constant, density or humidity and also unaffected by build-up due to the self-cleaning effect of the sensors.

The basics of ultrasonic level transmitters – how they work and what they’re used for

Ultrasonic Level Transmitters working principle

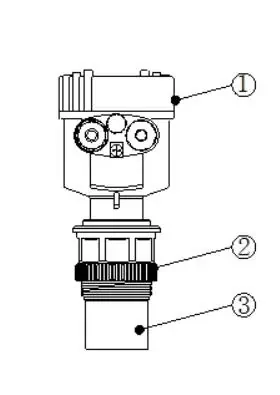

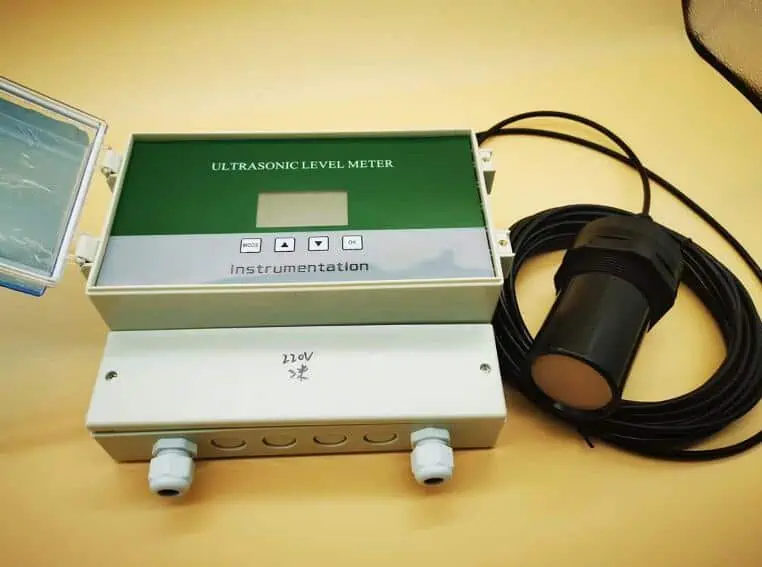

The Ultrasonic Level Transmitter consists of three parts: ultrasonic transducer (probe), drive circuit (module), and electronic display module.

The Ultrasonic Sensor is installed on the storage tank or process vessel. The sensor sends out a sound wave, which ricochets off the surface of the liquid and returns to the sensor. The time it takes for the sound wave to travel from the sensor to the liquid surface and return to the sensor is measured. This time delay is proportional to the level of the liquid.

The drive circuit processes the signal from the Ultrasonic Sensor, compensates for adverse conditions (temperature, pressure, etc) and converts it into a standard 4-20mA or 0-5/10 Vdc signal that can be read by a PLC, DCS or Display/Transmitter.

The Display/Transmitter converts the 4-20mA or 0-5/10 Vdc signal into a display reading in the unit of measure required (feet, inches, meters, centimeters, etc). Ultrasonic level transmitters can be outfitted with local displays and push button controls for easy configuration without the need of a laptop or other computer.

Applications

Ultrasonic level transmitters are used for inventory management and process automation in a wide range of industries. Applications include:

- Food & Beverage

- Water & Waste Water

- Chemical

- Petroleum

- Pharmaceutical

Read more about: Ultrasonic Level Sensor Applications

Featured Ultrasonic level transmitters

Ultrasonic level transmitter data sheet

Extended reading: liquid nitrogen level sensor

The benefits of using an ultrasonic level transmitter

– Ultrasonic level transmitters are easy to install and simple to use.

– Ultrasonic level measurement provides continuous, non-contact and maintenance-free level measurement of fluids, pastes, sludges and powdery to coarse bulk materials.

– Ultrasonic level transmitters are unaffected by dielectric constant, density or humidity and also unaffected by build-up due to the self-cleaning effect of the sensors.

Sino-Inst offers a wide range of Ultrasonic Level Transmitters that can be used in various industries for inventory management and process automation. If you have any questions about which Ultrasonic Level Transmitter is right for your application, please contact us and we will be happy to assist you.

Read more about 7 Level Senors for Tank Level Measurement

How to choose the right ultrasonic level transmitter for your needs

1. The ultrasonic level meter can only be used for the medium that can fully reflect sound waves and propagate sound waves. For the sound wave adsorption ability of the medium, it is not suitable to use ultrasonic level meter.

2. The ultrasonic level meter can not be applied to vacuum occasions, and not for negative pressure occasions. Because the propagation of ultrasonic waves need air medium. And the thin air environment is very unfavorable to ultrasonic propagation. Plus the sound attenuation will therefore increase. Ultimately, it will lead to serious errors in measurement or even can not be measured.

3. If the measured medium is a volatile liquid, or contains a large amount of water vapor, dust, bubbles, suspended particles and other media, the ultrasonic level meter should not be used.

This is due to the fact that when the sound waves from the probe of the ultrasonic level meter encounter the above medium, irregular reflection and scattering will occur. The probe will not be able to receive the normal signal. And these media will absorb the sound waves. This causes the attenuation of sound waves and affects the measurement results.

4. If there are obstacles or equipment that affect the propagation of sound waves inside the vessel. Then the ultrasonic level meter is not recommended.

5. Ultrasonic level meter can generally only be applied in the normal temperature and pressure range. If the pressure is too high, it will have a strong inhibiting effect on the sound speed of the acoustic wave. Eventually, it will affect the measurement accuracy, or even impossible to measure. And the temperature generally cannot exceed 100℃.

Tips for ultrasonic level transmitter installation

Before installing the ultrasonic level Transmitters, please read the instruction manual of the ultrasonic level Transmitters carefully. Work according to the instructions.

At the same time, it should be reconfirmed whether the model of the instrument matches the environmental requirements of the site such as process pressure, process temperature, and chemical properties of the medium. To ensure that the instrument can be used normally after installation.

To install the ultrasonic level meter, please observe the following operating rules:

- Try to avoid in-tank facilities such as ladders, heating equipment, limit switch brackets, etc. for installation.

- The ultrasonic beam must not intersect the feed stream. At the same time, pay attention to ensure that the highest material level does not enter the measurement blind area during installation. The ultrasonic level Transmitters must not be installed above the feed stream.

- When installing the ultrasonic level Transmitters, it should keep a certain distance from the tank wall. And keep the transducer perpendicular to the liquid surface as much as possible.

- When installed outdoors, the ultrasonic level Transmitters should take sunshade and rainproof measures. To avoid direct sunlight and reduce measurement errors caused by temperature changes. At the same time should also pay attention to moisture.

- The ultrasonic level Transmitters installed in the hazardous area must comply with the installation regulations of the national explosion-proof hazardous area. The intrinsically safe ultrasonic liquid level Transmitter is installed in the occasion with explosion-proof requirements, and the ultrasonic liquid level Transmitter must be grounded.

- When there is stirring in the container. The ultrasonic level Transmitters should be kept away from the agitator. In order to eliminate the false echo effect produced by the stirring blade. If foam or waves are created due to agitation, the still-pipe installation method should be used.

- When there is foam in the container. When feeding, stirring or doing other processing in the container, foam will be formed on the surface of some media, which will attenuate the signal of the ultrasonic level Transmitter. The sensor should be installed in a still-pipe or a guided-wave radar level Transmitters should be used. Guided wave radar level Transmitters measurements are not affected by foam and are ideal for this application.

- When there is airflow in the container. If there is a strong airflow or air vortex in the container, or if it is installed outdoors and in a very windy place. The sensor should be installed in a still-pipe or a guided-wave radar level Transmitters should be used.

Depending on the shape of the tank top of the container, the installation position of the ultrasonic level transmitter should be selected to avoid multiple reflection echoes between the liquid level and the top wall. In order to reduce interference, reduce noise signal and ensure the accuracy of detection.

Installation position of ultrasonic level transmitters

The reasonable installation position of the ultrasonic level transmitter should be determined according to the different top and internal structure shapes of the liquid container:

A. Grooved container:

- The support frame should be firm and reliable;

- The height of the intersection line of the beam emitted by the probe and the tank wall must be less than or equal to the minimum height of the liquid level to be measured;

- The installation height should be within the required range.

B. Arched container:

Meters cannot be installed on vaulted ceilings. It should be installed at 1/2 or 1/3 of the radius of the empowerment.

C. Conical container:

For conical containers with flat tops. The best place to install the meter is in the center of the top of the vessel. This ensures that you measure to the bottom of the container.

ultrasonic level sensor alternative products

More Level Measurement Solutions

Frequently

Asked

Questions

Sino-Ins offers 20 ultrasonic level transmitters products.

About 13% of these are ultrasonic level transducers, 4% are ultrasonic level indicators.

A wide variety of ultrasonic level transmitters options is available to you, such as free samples, paid samples.

Sino-Inst is an ultrasonic level transmitter supplier, located in China.

Ultrasonic level transmitter products are most popular in North America, Mid East, and Eastern Europe.

The United States, and India, which export 99%, 1%, and 1% of ultrasonic level transmitters respectively.

You can ensure product safety by selecting from a certified supplier, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.