Nitrogen Flowmeters are a type of flow meter that can measure the flow of nitrogen or liquid nitrogen. The common nitrogen flow rates are nitrogen and liquefied nitrogen. Nitrogen is often referred to as an inert gas. Used in metal processing in some inert atmospheres. When it is liquid, it is a common reagent for cooling, cooling, and freezing. Optimize your nitrogen system and save costs. Therefore, it is very important to accurately measure the nitrogen flow rate.

Nitrogen flowmeters are important to different industries. Inline Flow Measurement of Nitrogen needs to purchase the correct flow meter.

Please follow the purchasing guide below. You will find your most suitable Nitrogen flowmeter!

First, let’s take a look at nitrogen.

Next comes the most important question:

Nitrogen(N2) Flow Meter Types

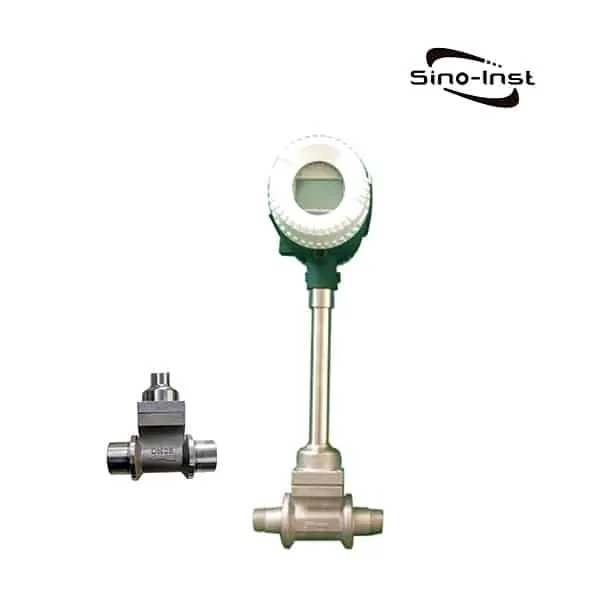

There are many types of Nitrogen gas flow meters. There are three types of flow meters commonly used to measure nitrogen. Precession vortex flowmeter, gas vortex flowmeter, thermal gas mass flowmeter. When selecting a model, it is necessary to select a suitable model and specification according to the parameters and cost that can be provided on-site.

There are 6 types of commonly used nitrogen flow meters:

Of course, which type of nitrogen flowmeter to use. Please make further confirmation according to your actual needs.

Guess you like: Gas Mass Flow Meter

Extended reading: Cryogenic Flow Meters | Liquid Nitrogen-Liquid Oxygen

Featured Nitrogen Gas Flowmeter

Cryogenic Liquid Nitrogen Flowmeters

Liquid nitrogen refers to liquid nitrogen. Liquid with extremely low temperature. In industrial production, liquid nitrogen can be used as a deep refrigerant. The low-temperature turbine flowmeter is used as a liquid nitrogen flowmeter, which can work at a low temperature of -196°C (-320.8 °F).

Liquid Nitrogen FlowMeter’s Turbine sensor structure at ultra-low temperature (-196℃) is made of special customized material, and it is equipped with a low-temperature resistant amplifier. Realize the instantaneous and cumulative flow monitoring of liquid nitrogen.

- Nominal diameter:

Common type (0.5~300) mm;

Anti-corrosion type (6~100) mm

Insertion type (80~600)mm - Medium temperature:

Ordinary type (-20~80)℃

High temperature type (-20~120)℃

Ultra-low temperature type (-196~80)℃ - Ambient temperature: (-20~55)℃;

- Accuracy: ±0.2%, ±0.5%, ±1%;

- Detector signal transmission line system: three-wire voltage pulse (three-core shielded cable);

- Power supply: voltage: 12V±0.144V, current: ≤10mA;

- Output voltage amplitude: high level ≥ 8V, low level ≤ 0.8V;

Gear flow meters are also a good choice for small-caliber liquid nitrogen measurement.

Gear flow transmitter is a type of positive displacement flow transmitter. It is a high-precision transmitter for measuring volume flow.

With the flow of the medium, the gears mesh and rotate. Under the action of the fluid flow, a pressure difference is formed at both ends of the instrument inlet and outlet. There is no need for a power supply. A pair of gears rotate freely. The cavity between the gears is filled with liquid. Discharge and measure the number of revolutions of the gear to know the flow of liquid and liquid flowing through the instrument.

- High pressure resistance (1.0-45MPa)

- High and low temperature resistance (-196℃-200℃)

- Can measure various viscous media

- High precision and repeatability

- Pulse output/analog output optional

- Wide range ratio (1:100)

- Wide measuring range

- Strong anti-corrosion and anti-fouling ability (acid and alkali)

Extended reading: liquid nitrogen level measurement

Case: Vortex flowmeter used for nitrogen gas flow measurement

The vortex flowmeter works according to the Karman vortex principle. Each pulse or certain current signal output by the meter represents a certain volume of the measured medium. The total number of pulses output during a period of time or the integral of the analog current quantity will represent the sum of the flow of the medium flowing in this period. That is, the instantaneous flow and cumulative flow we often say.

The vortex flowmeter measures a wide range of media, and it can measure gas, liquid and steam. It has a high working temperature and can withstand 350 degrees high temperature. No moving parts, safe and reliable measurement, no wear. The watch body is made of stainless steel, which is corrosion resistant and has a long service life.

Today we are mainly talking about the vortex flowmeter used for the measurement of nitrogen flow.

Give an example to illustrate:

A user measures nitrogen. The pipe diameter is 100mm. The usual flow rate is 950m3/h. Temperature and pressure.

The temperature and pressure of the site working conditions are not high. The flow rate is also within the measurable range of the vortex flowmeter.

It is understood that the user’s installation site environment is also better without major vibration or interference. Therefore, the user uses a nitrogen flowmeter, that is, a vortex flowmeter. The specific parameters are as follows:

- Measuring medium: nitrogen

- Medium temperature: normal temperature

- Working pressure: normal pressure

- Flow range: 120-1200m3/h

- Connection method: flange pipe type

- Installation direction: horizontal installation

- Body material: 304 stainless steel

- Sensor material: 304 stainless steel

- Resistance body material: 304 stainless steel

- Display mode: on-site LCD display

- Power supply mode: 24VDC

- Pressure rating: 1.0MPa

Vortex flowmeter functions:

- On-site LCD displays instantaneous flow and cumulative flow;

- Output 4-20mA signal output;

- The secondary instrument display can be selected, and it can be used in conjunction with PLC, DCS and other computer control systems;

- With temperature and pressure compensation, the accuracy is better;

- Can be connected to RS485 communication protocol;

- Optional battery power supply and power supply power supply;

- There are multiple connection options such as pipe type, plug-in type, threaded connection, and clamp type.

Features of vortex flowmeter:

- The nitrogen flowmeter has no moving parts, no wear, dirt resistance, no mechanical maintenance, and long service life;

- The overall structure design of the instrument is reasonable, the dynamic measurement range is wide, and the pressure loss is small;

- The measurement is not affected by temperature and pressure and is resistant to high temperatures. High pressure.

Vortex flowmeter installation conditions:

- There is a straight pipe section at 15-20D. Downstream straight pipe section 5-10D;

- Ensure that the medium is full of the pipeline;

- Try not to install it in a place with strong vibration or interference. If it must be installed in an environment with vibrations, shock absorption measures should be taken.

FAQ

You may like:

Sino-Inst is a well-known Exporter, Supplier, Trader, and Service Provider of Nitrogen flowmeters. Sino-Inst offers over 50 Nitrogen flowmeters for flow measurement. About 50% of these are differential pressure flow meters, 40% are the vortex flow sensor, and 20% are the gear flow meter and mass flow meter.

A wide variety of Nitrogen flowmeters options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of flow measurement instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.