Pressure Transducers and Water Pipe Pressure Measurement

Water pressure transducers also called a water pressure sensor,

are pressure transmitters that can measure water pipe pressure.

For the water level/water depth measurement,

in the tank, or in the well, we can use electrical transmitters, stainless steel body, IP65-IP6, 4-20ma output.

Sino-Inst applies application expertise to design and manufacture pressure sensors and transducers for the water industry.

Various factors impact the selection and long term use of water pressure sensors and transducers, in residential, commercial, and irrigation systems.

Sino manufactures various products with design features, to offer excellent accuracy and long term stability.

Below is some basic information to review, before making a decision on the type of pressure sensor technology, as well as the electrical and mechanical features required.

Sino-Inst also offers pressure transmitters with 0-5V/0.5-4.5V, just contact us now.

Water Compatibility

A pressure sensing element will come in contact with varying pH levels, depending on the type of water, chemicals added, and the quality of the water purification process.

Sino packages pressure sensors using silicon strain gages, mounted onto a one-piece, 316L stainless steel sensing element.

316L SS offers excellent media compatibility for residential, and commercial water applications and is an NSF61 compliant material.

Environment

Rain, ice, dust, and pressure washers can cause water to seep into sensor housings, and cause the electronics to short.

Sino offers sealed gauge reference pressure sensors to protect the electronics from these conditions.

Electrical Isolation

Improper grounding and lightning strikes can cause electrical failures of pressure sensors, as a result of isolation failure.

Sino can include custom electronics and a sensing element to withstand 500VDC isolation to work in extreme electrical conditions.

The use of a 4-20mA output signal for transmission lengths greater than 15 feet in environments with electrical noise, will help prevent signal loss or noisy signal conditions.

Read more about: What is a pressure sensor and how it works?

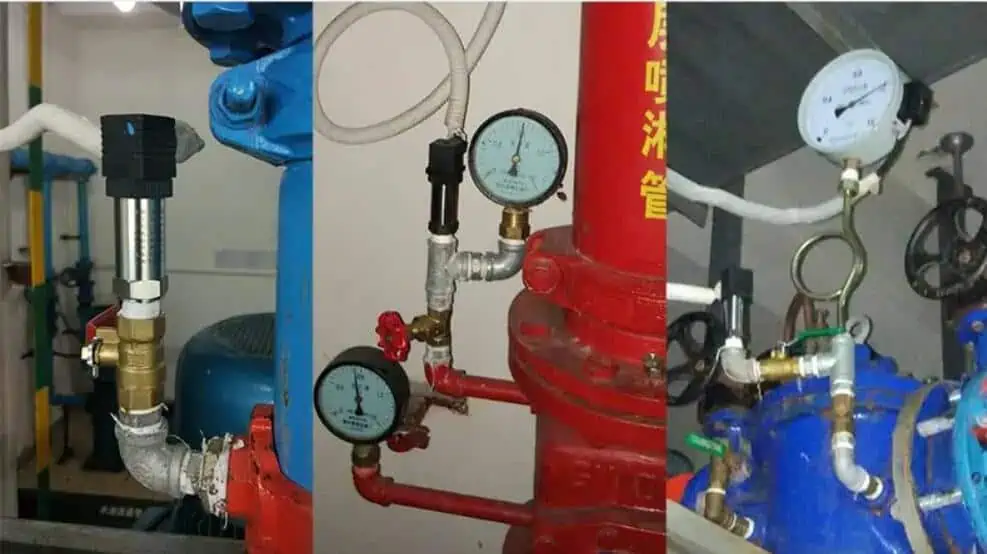

Using Pressure Transducers for Water Pipe Pressure Measurement at Water Distribution Utilities

Inlet and Outlet Water Pipe Pressure Measurement in Clean Water Systems

Clean water systems use lift stations and gravity feed reservoirs, to pump water between locations.

In some residential settings, lift stations and water towers alone cannot supply enough pressure, to provide users at higher elevations with clean water.

Also, water reservoirs and water towers, that experience sudden, large draws of water need replenishment.

Pressure-controlled variable frequency drive pumps (VFDs) are used with pressure transducers, for reliable electronic pressure measurement to determine when extra pressure and flow are required by users.

Pressure transducers are used to monitor water pressure, at elevation, in reservoirs, and the rate of change in each.

VFD pumps interpret the pressure inputs and output the necessary increase or decrease in pump output pressure and flow rate.

Of course, in the water supply or wastewater treatment industry, the measurement of water flow is also very important. For example, if you need to measure the flow of wastewater in a 2-inch pipe. Then you can refer to Magnetic Flow Meters Guides.

Electronic Pressure Transducer Applications for Water Pipe Pressure Measurement in Clean Water Systems

Pressure transducers are used for inlet and outlet water pipe pressure measurement, in clean water systems at public utilities.

An electronic pressure transducer is typically used in water distribution applications such as:

- Pump intake pressure measurement

- Pump output pressure measurement

- End location (reservoir, elevated piping, etc.) pressure measurement

An important part of pressure transmitter selection is ensuring that any electronic pressure transducer used is compatible with potable water.

Pressure transducers are responsible for monitoring the pressure, at various locations throughout clean water systems and often interface with VFD pumps to show, when increased pressure or flow rates are necessary.

The SI-200 and SI-390 electronic pressure transducers are designed for long lifetimes, in both inlet and outlet pipes of clean water systems.

They can usually be delivered within days in a wide variety of configurations.

In addition to measuring water pressure, you may also need to measure water depth. We also provide Portable Ultrasonic Water Depth Gauge.

How to select a water pressure transducer for water pressure?

- Absolute or gauge pressure measurement

- Cable or flying lead pressure transmitter wiring

- Media compatibility for pressure transmitters

- Moisture resistance in pressure transmitters

- Pressure transmitter accuracy and errors

- Radiofrequency (RFI) and electromagnetic interference (EMI) in pressure transmitters

- Standard or flush diaphragm pressure transmitters

- Vibration resistance in pressure transmitters

Read more about: What is industrial pressure transmitter?

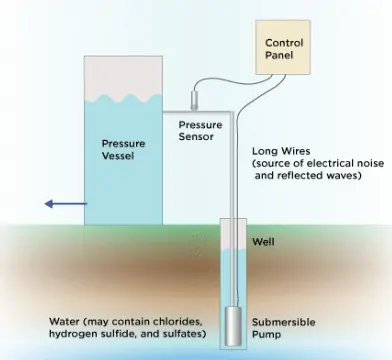

Submersible water pressure sensor

Submersible pressure transducer with 4-20mA output is Hydrostatic Level Sensor for level measurement. Submersible pressure transducer is based on the measured liquid static pressure proportional to the height of the liquid Principle. Convert static pressure into electrical signal. After temperature compensation and linear correction. Convert into standard electrical signal. Generally 4 ~ 20mA / 1 ~ 5VDC. It can also be called “static pressure liquid level gauge, liquid level transmission Device, liquid level sensor, water level sensor “. Bullet, cage, and flush tip models are available. Applications include pumps, downhole, oil tanks, lime slurry, and water tanks. There is a miniature submersible transmitter that is low power voltage.

Extended reading: What is a pressure sensor?

Liquid pressure sensor for water pipe

Hydrostatic Level Sensor (Best Price), also called Hydrostatic level transmitter. Continuous level measurement in liquid applications with pressure sensors.

Liquid pressure sensor is widely used for pressure measurement of various liquids. Like water or oils. IP68 waterproof.

Hydrostatic level transmitter is also called hydrostatic level gauge. The rod-type Hydrostatic level transmitter 4-20mADC standard signal output. Flange or threaded installation. Can withstand high temperatures up to 450 ℃.

Well water level sensor is to apply Hydrostatic Level Sensor to deep well. Well water level sensor submerged in deep well work together with submersible water pump. Range 300m ~ 1000m.

Submersible Level Transmitter is made of Anti-corrosive all-tetrafluoroethylene(PTFE) material. It has high temperature resistance, corrosion resistance and anti-clogging.

What are the different types of pressure sensors?

There 4 main types of pressure sensors based on this:

- Strain Gauge Pressure Transducers

- Capacitance Pressure Transducers

- Potentiometric Pressure Transducers

- Resonant Wire Pressure Transducers

More about Industrial Pressure Sensors

FAQ

How does a pressure transducer work?

The installation of the pressure transducer measurement system,

consists of three parts, namely the laying of the pressure guiding tube,

the laying of the electrical signal cable and the installation of the differential pressure transmitter.

During the operation of the pressure transmitter, the pressure of the medium is transmitted to the central measuring diaphragm.

Through the isolating diaphragm and the silicone oil, and the pressure difference from the double-sided pressure guiding tube is received on the double-sided isolating diaphragm, where the membrane is measured.

The sheet functions as a resilient element and is deformed by the pressure difference.

There is a positive proportional relationship, between the displacement of the measuring diaphragm and the differential pressure.

And under the influence of the displacement of the diaphragm, the capacitance of the differential capacitor also changes.

And the measuring circuit converts it into a DC current signal of 4-20 mA.

Extended reading: Hydrostatic Pressure Transmitter

Where are pressure transducers used?

Pressure transducers are mainly used in the following areas:

Petroleum, petrochemical, chemical. Matching with throttling devices to provide accurate flow measurement and control. Measures pressure and level in pipes and tanks.

Electricity, city gas. And other companies and businesses require high stability and high precision measurement and other places.

Pulp and papermaking are used in places that require chemical-resistant liquids and corrosion-resistant liquids.

Steel, non-ferrous metals, and ceramics are used in furnace pressure measurement and other places that require high stability and high precision measurement. They are also used in places that require stable measurement under strict control (temperature, humidity, etc.).

Machinery and shipbuilding, used to strictly control the place where high precision is required for stable measurement.

Extended Reading: 4 wire pressure sensor wiring diagram

What is pressure sensor and how it works?

A pressure sensor is a device or device that can sense a pressure signal and convert the pressure signal into a usable output electrical signal according to a certain rule.

A pressure sensor usually consists of a pressure-sensitive element and a signal processing unit. According to different test pressure types, pressure sensors can be divided into gauge pressure sensors, differential pressure sensors and absolute pressure sensors. A pressure sensor is the core part of pressure transmitter. More.

Extended Reading: Wireless Water Meter

Read more about: How to Calculate Pressure Drop in a Pipe?

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.