Vortex flow meter also called Vortex shedding flow meter. Vortex Flow Meter is suitable for flow measurement of steam and various liquids and gases.

What is Vortex Flow Meter?

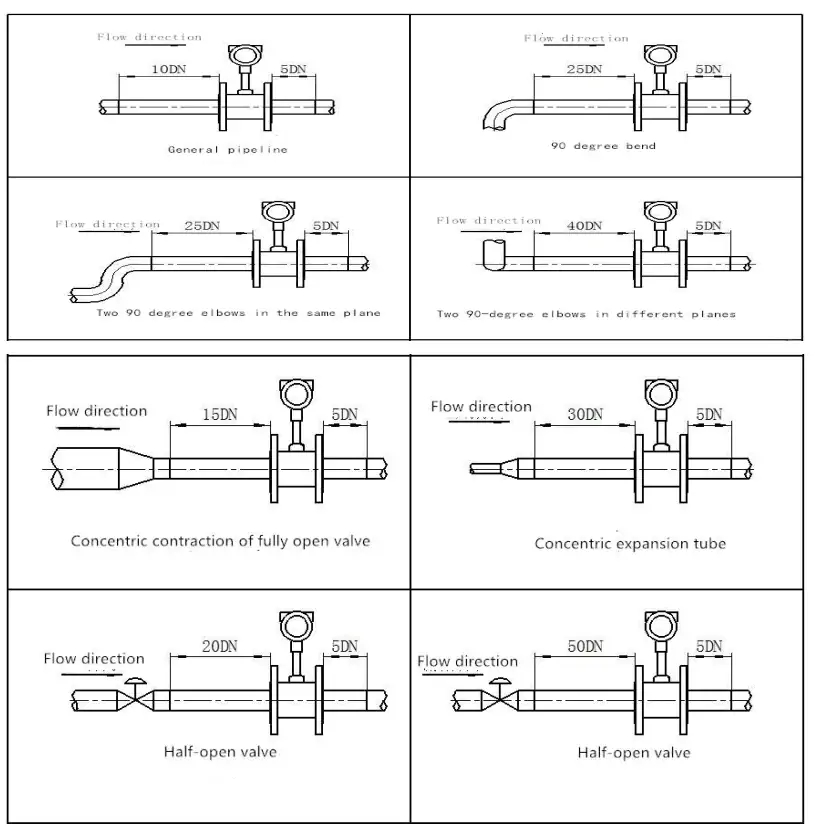

The vortex flowmeter is a volume flow meter that measures the volume flow of gas, steam, or liquid, the volume flow of standard conditions, or the mass flow of gas, steam, or liquid-based on the Karman vortex principle. When the fluid flows through the dust collector rod of the vortex flowmeter, a vortex is formed. The frequency of vortex shedding is proportional to the fluid velocity. Temperature and pressure compensation can be configured.

Sino-Inst offers a variety of Vortex flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Featured Vortex Flow Meters

Vortex Flow Meter Applications

The vortex flowmeter is mainly used in the flow measurement of industrial pipeline medium fluid. The medium can be gas, liquid, steam, etc.

Read more: Vortex flow meter for Steam Flow Measurement

The main scope of action includes:

- During industrial production, such as metallurgy, coal, electric power, chemical, pharmaceutical, environmental protection and other manufacturing;

- Energy measurement. Including the scientific measurement of primary and secondary energy. Such as coal, petroleum gas, natural gas, etc., to achieve energy saving and reduce consumption;

- Environmental protection engineering. Including flow measurement of flue gas, sewage, etc.;

- Transportation. Including pipeline transportation for control, distribution and scheduling, and better economic accounting through measurement results.

- Turbine flowmeter: Measuring oil, liquid

- Sewage flow meter: Measuring acid, sewage

- Electromagnetic flowmeter: Measuring acid, alkali, sewage

- Steam flow meter: Measure gas, steam

- Orifice flowmeter: Measuring steam, gas, liquid

- Insertion vortex flowmeter: Gas, steam, liquid

Extended reading: High Pressure Rotameter for Liquids/gas-Upto 25 Mpa

Vortex Flow Meter Working Principle

Vortex flowmeter is a speed-type flowmeter produced according to karman’s vortex principle,

which can be used for the measurement and measurement of conventional gas, steam and

liquid.

Vortex flow sensor has high precision and wide range ratio, no moving parts in use, which can

improve mechanical stability and reduce maintenance.Vortex flowmeter is almost not affected by the temperature, pressure and composition of medium when measuring the volume of working condition.

Therefore, it is convenient to calibrate the instrument, so vortex street flow sensor is widely used in production and life.

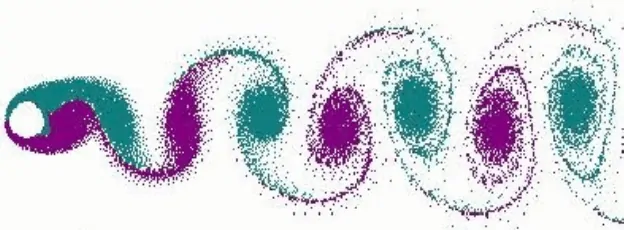

When a trigonal column vortex generator is set in the fluid, regular vortices are generated alternately on both sides of the vortex generator, which is called Carmen vortex.

The vortex columns are arranged asymmetrically downstream of the vortex generator. Vortex flowmeter is produced according to this principle.

Vortexes are generated by generating bodies and the number of vortexes is detected by high-sensitivity sensors. In a certain range, the number of vortexes generated is proportional to the flow rate.

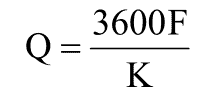

In vortex flowmeter, the relationship between flow rate and the number of vortexes generated

can be expressed by the following formula:

Q:Operating volume flow of the measured medium. The unit is m3/h。

F:Frequency of the number of vortices produced by the generating body. The unit is Hz.

K:Refers to the calculated or calibrated flow coefficient. It represents how many frequency signals per cube. the coefficient is usually obtained by calibration.

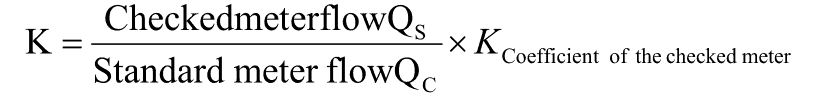

The formula of standard table method calibration coefficient K:

The formula can also be used for flow correction.

More about vortex flow meter working principle wikipedia.

Endress+Hauser has a great explanation video about vortex flow meter working principle. Let’s take a look!

What are vortex flow meters used for?

Vortex flowmeter is mainly used for industrial pipeline medium fluid flow measurement. Such as gas, liquid, vapor and other media. Here are some related applications.

Extended reading: Ultrasonic Flow Meters Types & Technical Guide

Vortex Flow Meter Price

Price is always a topic of concern. Different types of vortex flowmeters can be found online, and the prices of different vortex flowmeter manufacturers are not consistent. The final quotation is still subject to the actual working conditions on site.

Vortex flow meters have different prices due to different calibers, different materials, different media, and different functions! The price list of vortex flowmeter is attached below for reference.

This is a reference price only. Not the price of the order transaction. Please contact our sales engineers. According to the measurement conditions, choose the appropriate model to confirm the price.

| Full-tube piezoelectric vortex flow sensor (Including special flanges, bolts, and nuts) | DN15 | 515 | 559 |

| DN20 | 326 | 312 | 415 |

| DN32 | 357 | 312 | 415 |

| DN65 | 349 | 363 | 488 |

| DN80 | 378 | 407 | 488 |

| DN125 | 459 | 503 | 606 |

| DN250 | 518 | 569 | 509 |

| DN300 | 500 | 544 | 662 |

| DN600 | 544 | 588 | 662 |

Extended Reading: Types Of Crude Oil Flow Meters

Related Products:

Extended reading: Flow Totalizer F3000X for Data collection and calculation

Sino-Inst, Manufacturer for Vortex Flow Meters, like gas vortex flow meter, liquid vortex flow meter, sanitary vortex flow meter, insertion vortex flow meter, steam vortex flow meter, and natural gas vortex flow meter.

Sino-Inst’s vortex Flow Meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.