What Is a Solid Flow Meter?

The solid flow meter is suitable for the measurement of solid mass flow in a wide range of metal-enclosed pipelines from kg/h to t/h. The system is suitable for online monitoring of the flow of solids such as powder, dust, pellets, granules, etc., which are pneumatically conveyed or in free fall (1nm-20mm). Solid flow meters are also called solid powder flow meters, intelligent electrostatic powder flow meters, solid dust flow meters, coal powder flow meters, mineral powder flow meters, lime flow meters, cement flow meters, flour flow meters, petroleum coke powder flow meters.

Sino-Inst supplies GTL/C powder flow meter. The intelligent electrostatic powder flow meter continuously measures bulk solid materials in a process. The ring sensor is used. It is suitable for the measurement of solid mass flow in a wide range of metal-enclosed pipelines from kgh to th. The system is suitable for online monitoring of solid flow such as powder and dust conveyed by pipeline pneumatic conveying. Also known as pipeline solid flowmeter, solid powder flowmeter, intelligent electrostatic powder flowmeter, solid dust flowmeter, microwave solid flowmeter, etc. Applicable to: coal powder, mineral powder, lime, cement, flour, petroleum coke powder, etc.

Solid Flow Meter Parameters

| Pipeline gas pressure | -0.1Mpa~2 Mpa |

| Pipeline gas flow rate | 1m/s~30 m/s |

| Pipeline gas temperature | -50℃~260℃ (450℃ high temperature customized) |

| Outer diameter of pipe | 10mm~600mm (Standard 5, 10, 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, etc., special specifications can be customized) |

| Accuracy class | ±5% of full scale |

| Measuring range | 0-20/100/500/2000Kg/h (10kg measuring range customized) |

| Dust size | 0.1uM~200 uM |

| Sensor structure | Unobstructed pipeline |

| Operating environment electromagnetic field | High value at 50 Hz = 60A/m |

| Operating environment humidity | No condensation 90% |

| temperature | PTFE lining: -20+120℃ High temperature type PTFE lining -20-+260℃C |

| Operating environment vibration | High continuous oscillation, any direction, any frequency: root mean square value 2g (20m/s2) |

| Operational environmental protection | Protection grade: IP66/NEMA4 aluminum alloy shell |

| Transmitter power supply | 24V (available in the range of 15V~32V) |

| Transmitter output | 4~20mA isolated output |

| Response time | 1 second |

| Power consumption | Big 3W |

| Zero drift | Less than 1% |

| Full scale drift | Less than 1% |

Extended reading: Radar level sensor for solids – Dust solid level measurement

Solid Flow Meter Working Principle

The Solid Flow Meter is based on the theory of contact electrification of solid materials.

The powder will accumulate a certain degree of electric charge during the pneumatic conveying process. This phenomenon is caused by the continuous collision, friction, and separation process between the powder particles and the particles, and between the particles and the tube wall.

The sensor part of the Solid Flow Meter is composed of a short stainless steel tube, a ring electrode, and an insulating layer. The two ends of the short tube are connected to the pipeline through a flange. The grounded metal tube wall plays an electromagnetic shielding role.

When the charged particles pass through the measuring pipe section, based on electrostatic induction, the sensor senses the charge number of the charged particles. The front-end circuit is connected to the sensor and the signal is amplified. Then it is calculated and processed by a converter with a high-speed central processing unit core. The flow rate is calculated and processed. The signal is converted into a standard current signal linearly related to the powder flow rate. It is used for flow control and adjustment.

Extended reading: Stainless steel flow meters|304-316 optional

Solid Flow Meter Features

- Suitable for the conveying process of pneumatic conveying device;

- Intelligent design, can measure almost all solid materials;

- Integrated design, sensor, transmitter and display are integrated;

- No throttling parts, no pressure loss during measurement;

- Non-contact measurement, not affected by temperature, pressure, and vibration.

Solid Flow Meter Advantages

- Advanced toroidal charge sensor has the advantages of fast response, high sensitivity and accurate measurement;

- The measurement speed is very fast and the static repeatability is good;

- Static particles such as sediments have no effect on the work of the product;

- The stainless steel shell is firm and durable, and the PTFE lining is resistant to high temperature and pressure;

- Easy installation and maintenance-free.

Solid Flow Meter Application

- Power plant boiler coal injection, pulverized coal quality, concentration, flow measurement;

- Activated carbon flow detection of waste incineration power generation in power plants;

- Limestone powder flow measurement during pneumatic conveying;

- Sodium phosphate flow monitoring;

- Blast furnace coal injection flow detection.

Application industry:

Chemical, chemical fiber, glass manufacturing plants, food, papermaking, mining and metallurgy, environmental protection, steel, power stations, petroleum, cement manufacturing, and other industrial fields.

It is used to measure the volumetric flow of various small particles such as coal powder, mineral powder, lime, cement, flour, petroleum coke powder. etc.

Read More about Chemical Flow Meter Guide

How Do You Measure the Flow of Solids?

The Solid Flow Meter is based on the theory of contact electrification of solid materials. The powder material will accumulate a certain degree of electric charge during the process of pneumatic conveying or free fall.

Solid Flow Meter uses today’s advanced ring sensor. It can effectively capture every charged powder particle signal that passes through the ring sensor. It is amplified, shaped, and filtered by an amplifier circuit, and then processed by a high-speed processor. The final output is linear with the powder flow The standard current signal of the relationship.

The GTL/C powder flow meter is suitable for the measurement of solid mass flow in metal-enclosed pipelines with a wide range from kg/h to t/h. The system is suitable for online monitoring of the flow of solids such as powder and dust conveyed by pneumatic conveying. It can be widely used in electric power, metallurgy, cement, pharmaceutical, chemical, food manufacturing, and other industries.

Solid Flow Meter Selection Guide

When looking for a solid flow meter suitable for your process, Sino-Inst recommends that you make the best choice based on the following conditions:

- Maximum flow

- Material particle size

- Material temperature

- Bulk density/bulk density

After finding a solid flow meter suitable for your process according to the application conditions and material characteristics, you should also consider the following influencing factors:

- Wear: Wear will affect the life of the measuring piece. It is worth noting that changes in material flow will also cause significant wear.

- Adhesion: Materials should not adhere or accumulate on the surface of the measuring piece, as this will cause calibration deviations due to the buffering effect of adhered or accumulated materials.

- Corrosive: Corrosive materials will damage the flowmeter components. Corrosive gases are also worth noting.

- Airflow: Unstable and unpredictable airflow will affect the accuracy of airflow.

- Unsteady material flow: For uneven material flow, please choose a displacement sensor type solid flowmeter. Because the displacement sensor type solid flowmeter has the characteristics of mechanical hydraulic buffering.

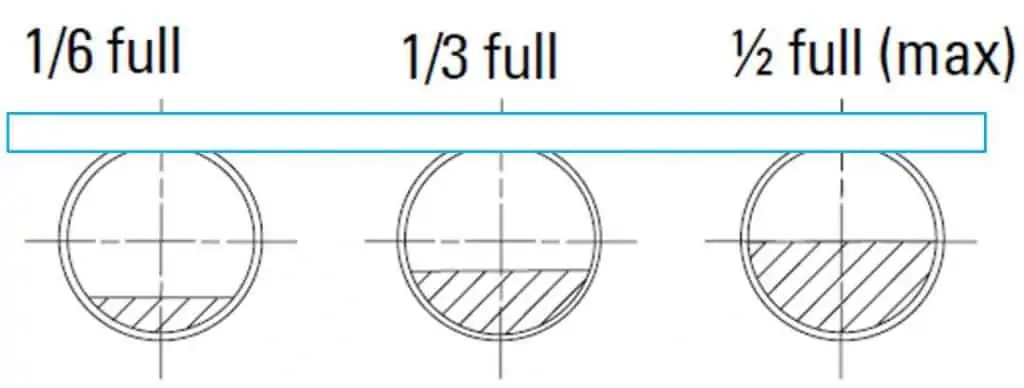

Selection of the capacity of solid flowmeter draft tube:

Extended reading: GWR Solid Level Sensor-for Cement silo-Ash powder measure

Impact Plate Solid Flow Meter

Impact Plate Solid Flow Meter is used for metering equipment for powdery and granular materials with strong fluidity. Mainly suitable for closed material flow. Installation is restricted. Other occasions where similar products cannot be adapted. It is widely used in building materials, cement, chemical industry, coal, mining, ceramics, glass, metallurgy, grain, fertilizer, feed, port, electric power, coking, environmental protection and other industries.

Flow Meter Selection Guide 101: Find the Perfect Fit for Your Application

Microwave Solid Flowmeter-Gas Powder Explosion-Proof

The microwave solid flow meter uses the latest microwave technology. It is suitable for the measurement of solids in metal pipes.

Online flow measurement. All powder, dust, crumbs, and particulate matter can be measured repeatedly. The measurement range is as small as kilograms per hour and as large as tons per hour.

A microwave solid flowmeter is suitable for online measurement during pneumatic conveying or free fall. Therefore, it is an alternative product of a cost-effective weighing system.

MONITOR level monitor and display can be used on various occasions to detect the flow/non-flow state of powder and solid particles. Choose SFD-2 solid level monitor or SFI solid level display. Mainly based on the output type (relay or analog Quantity) requirements.

More Featured Flow Meters:

You may like:

Sino-Inst offers over 50 flow meter for flow measurement. About 50% of these are differential pressure flow meters, 40% is the liquid flow sensor, and 20% are Ultrasonic Level Transmitter and mass flow meter.

A wide variety of flow meters options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of flow measurement instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.