A sludge flow meter refers to a flow meter that can be used to measure the flow of sludge.

What kind of flowmeter can be used for sludge flow measurement?

According to the characteristics of the sludge medium, the flow rate of the sludge can be measured by using an electromagnetic flowmeter. The electrode material uses a tantalum electrode. The lining material uses a ceramic material or tetrafluoroethylene. This can solve the flow measurement condition of the sludge.

Sludge treatment (sludge treatment) refers to the reduction, stabilization, and harmless processing of sludge such as thickening, tempering, dewatering, stabilization, drying, or incineration. The higher the degree of sewage treatment, the more sludge residues that need to be treated.

Why use an electromagnetic flowmeter to measure the sludge flow rate?

The main reason for using an electromagnetic flowmeter to solve the flow of sludge is its low cost, high measurement accuracy, and good stability. Many flows measuring instruments can meet this requirement.

Featured Sludge Flow Meters

Read more about: Different Types of Flowmeters – Technical and Application Analysis

Return Activated Sludge

The wastewater treatment plant uses a secondary treatment process called activated sludge. This process converts non-sedimentable substances into biological flocs. This substance is produced in the aeration tank and settled in the final sedimentation tank.

Activated sludge is an aerobic process. It can promote the health of microorganisms and ensure effective treatment. The balance between food and oxygen and microorganisms must be maintained for optimal treatment. An element of maintaining biomass is to return a part of the sedimentation sludge from the final sedimentation tank to the aeration tank to maintain the balance of the biological system. This part of activated sludge is called RAS (Returned Activated Sludge).

The RAS is returned to the aeration tank via a variable-speed centrifugal pump. Accurate flow rate measurement is essential to ensure that the proper ratio of “food to microorganisms” is maintained. The RAS flow rate is determined by a microbiological health laboratory analysis, and the flow rate is adjusted accordingly.

Extended reading: Insertion Ultrasonic Water Flow Meter – Designed for Agricultural Irrigation, Garden Management

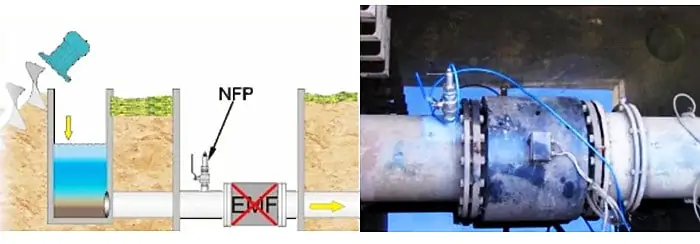

Sludge Flow Measurement of Return Activated Sludge Pipe

1 Project background

- DN 400mm stainless steel pipe;

- Full tube

- High pollution load, suspended solids content as high as 1%.

2 Measurement requirements

- Trouble-free and stable measurement of the horizontal conveying pipe of the return sludge conveyed by the screw pump lifting equipment;

- Due to high pollution load and gas load. The two existing measurements. Electromagnetic flowmeter + external clamp ultrasonic time difference method. Neither can work reliably or at all;

- The installation cost is low.

3 Solution

- Use NFP type cross-correlation flow measurement system;

- A hole was drilled upstream of the existing electromagnetic flowmeter. The NFP mounting piece was welded to the existing pipeline;

- Install a ball valve that can remove the sensor during operation, adjust and fix the cross-correlation sensor.

4 Advantages

- Simple and fast upgrade and transformation of existing facilities;

- The old flow measurement equipment does not necessarily need to be dismantled;

- Although the concentration of suspended solids in the water is high, the flow measurement is still reliable.

Read more about: Shop 101: Key Factors In Selecting A Pipe Flow Meter

Extended reading: Micro flow meters for low flow liquids

Advantages of electromagnetic flowmeter in sludge measurement

- The electromagnetic flowmeter has no mechanical inertia. Responsive. Can measure instantaneous pulsating flow. It can also measure the flow in both directions.

- The output of the electromagnetic flowmeter is only proportional to the average flow rate of the measured medium. It has nothing to do with the flow state (laminar or turbulent) under symmetrical distribution. Therefore, the electromagnetic flowmeter has a very wide range. The measurement range can reach 100:1, and some even reach the operable flow range of 1000:1.

- The sensor structure of the electromagnetic flowmeter is simple. There are no moving parts in the measuring tube, nor any throttling parts that hinder fluid flow. So when the fluid passes through the flow meter, it will not cause any additional pressure loss. It is one of the flow meters with low energy consumption in the flowmeter.

- The industrial electromagnetic flowmeter has a very wide caliber range. From a few millimeters to a few meters. Moreover, there are real-flow calibration equipment with a diameter of 3m in China. Laid a foundation for the application and development of electromagnetic flowmeters.

- The electromagnetic flowmeter is a volume flow measuring instrument. During the measurement process, it is not affected by the temperature, viscosity, density and conductivity (in a certain range) of the measured medium. Therefore, the electromagnetic flowmeter only needs to be calibrated by water. It can be used to measure the flow of other conductive liquids.

- It can measure the flow of dirty medium, corrosive medium and suspended liquid-solid two-phase flow. This is because there are no obstructing flow parts inside the meter measuring tube. The fluid to be measured is only in contact with the inner lining of the measuring tube and the electrode, and the material can be selected according to the nature of the fluid to be measured.

For example, use polytrifluoroethylene or polytetrafluoroethylene as the lining. It can measure various corrosive media such as acid, alkali and salt. The use of wear-resistant rubber as the inner lining is particularly suitable for measuring liquid-solid two-phase flows such as mineral slurry and cement slurry with solid particles and greater wear, as well as various suspended liquids such as fiber-containing liquids and pulps.

Extended reading: Orifice Plate Flow Meter

Can electromagnetic flowmeter measure sludge fluid with 85% moisture content?

Yes, there is no problem at all. I am the technology of the electromagnetic flowmeter manufacturer, and the measurement is no problem. It is only when the density of the sediment particles reaches a certain level. There will be peak fluctuations. However, the measurement is no problem.

Extended reading: ultrasonic sludge level meter

Which lining material electromagnetic flowmeter is used for sludge flow meter?

What kind of flowmeter can be used for sludge flow measurement. According to the characteristics of the sludge medium, the flow rate of the sludge can be measured by using an electromagnetic flowmeter. The electrode material uses tantalum electrode, and the lining material uses ceramic material or tetrafluoroethylene. In this way, the sludge flow measurement conditions can be solved.

More about:

Learn More about Sludge Treatment

Before sludge treatment, we must first understand the classification of sludge:

- Treatment of physicochemical sludge discharged from sedimentation tank or thickening tank of waterworks. It is a medium and fine-grained organic and inorganic mixed sludge. The compressibility and dehydration performance are average.

- The remaining activated sludge discharged from the secondary settling tank of the domestic sewage plant is hydrophilic, fine-grained organic sludge, with poor compressibility and poor dehydration performance.

- Treatment of physicochemical and biochemical mixed sludge discharged from the thickening tank produced by industrial wastewater treatment. It is a medium-fine-grained mixed sludge. The dewatering performance of the fiber-containing body is better. The other compressibility and dewatering performance are average.

- The physical and chemical fine-grained sludge produced by the physical method and chemical method discharged from the thickening tank from the industrial wastewater treatment. It belongs to the fine-grained inorganic sludge. The compressibility and dewatering performance are general.

- Physical and chemical precipitation of coarse-grained sludge produced by industrial wastewater treatment. It belongs to coarse-grained hydrophobic inorganic sludge. It has good compressibility and dewatering performance.

Extended reading: Stainless steel flow meters|304-316 optional

You may like:

Extended Reading: Special Magnetic Flowmeter Installation situation

Sino-Inst offers Sludge flow meter products. About 85% of these are Magnetic flow meters, 3% are Ultrasonic water meters. A wide variety of Sludge flow meter options are available to you, such as free samples, paid samples.

The top-selling countries or regions are China, India, and Israel, which supply 99%, 1%, and 1% of sewage flow meter respectively. Sludge flow meter products are most popular in Domestic Market, Mid East, and North America. You can ensure product safety by selecting from certified suppliers, with ISO9001, and Other certifications.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.