What does SCADA stand for?

SCADA is the abbreviation of Supervisory Control And Data Acquisition. Namely data acquisition and monitoring control system. SCADA system is also called monitoring configuration software, which is widely used in enterprise equipment management of equipment automatic operation.

What is a SCADA system?

SCADA is a data acquisition and monitoring control system. The scada system is a computer-based production process control and scheduling automation system. It can monitor and control the operating equipment on site. Because each application field has different requirements for scada, the development of scada system in different application fields is not exactly the same.

The scada system is the most widely used in the power system, and the technology development is also the most mature. It is one of the most important subsystems of the energy management system (EMS system). It has the advantages of complete information, improved efficiency, correct control of system operation status, accelerated decision-making, and can help quickly diagnose system fault status. Now it has become an indispensable power dispatcher. Missing tools.

The scada system plays an irreplaceable role in improving the reliability, safety and economic benefits of power grid operation, realizing the automation and modernization of power dispatching, and improving the efficiency and level of dispatching.

How does SCADA work?

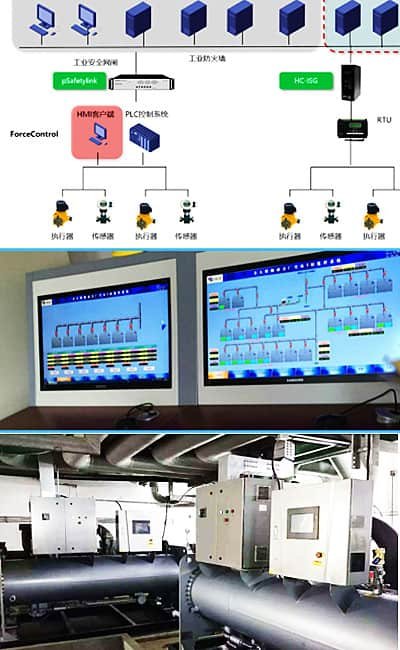

The SCADA system deploys multiple software and hardware elements, allowing industrial organizations to: monitor, collect and process data.

Connect and control machines and equipment such as valves, pumps, motors, etc. through HMI (Human Machine Interface) software.

Log the event to a log file.

In the basic SCADA architecture, sensor or manual input information is sent to PLC (Programmable Logic Controller) or RTU (Remote Terminal Unit), and then sent to a computer with SCADA software.

SCADA software analyzes and displays data to help operators and other workers reduce waste and improve the efficiency of the manufacturing process.

An effective SCADA system can greatly save time and money. Many case studies have been published, highlighting the benefits and savings of using modern SCADA software solutions such as ignition.

What is SCADA used for?

The SCADA system has a wide range of applications, and it can be used in the fields of data acquisition, monitoring and control and process control in electric power, metallurgy, petroleum, chemical, gas, railway and other industries. Its functions mainly focus on four aspects: real-time collection of production data, process monitoring of production equipment, abnormal alarms of production equipment, data analysis, data reports and dashboard display. Its characteristics mainly reflect the following aspects.

- It supports more than 5000 communication protocols and meets the communication requirements of 99.99% of controllers and instruments on the market. Get through the automated hardware system and the information transmission of the information software system.

- Isolate office network IP and industrial equipment IP in hardware to avoid IP conflicts.

- Intuitive display of production dynamics, direct or indirect control of on-site equipment, to meet the needs of visual management.

- Perform statistical analysis of data and display it through the dashboard.

The SCADA system is centered on the data collected in the production process. It is related to the distribution of people, machines, materials, methods, environments, testing, and R&D. It is based on the data generated during the operation of production equipment. It is also a big Most companies are most concerned about.

Secondly, the SCADA system is aimed at the application needs of the above-mentioned manufacturing enterprises. At the same time, it will give play to its own unique advantages to bring improvements and benefits to the enterprise.

- Help companies collect all kinds of data in the production process in real time. Instead of manual operations, it also avoids certain losses caused by personnel errors. Not only improves work efficiency, but also enables real-time monitoring of production All abnormal data in the process provides another layer of guarantee for the quality of the product.

- The SCADA system provides the production data of each device, which makes the production situation intuitive and clear, and facilitates the analysis of the production situation by the management personnel of the enterprise, and at the same time helps the enterprise optimize the production, making the production plan more scientific and reasonable.

- Realize the digital and intelligent improvement of the management process of products, production schedule, production efficiency, quality information, equipment operation, etc., and optimize the digital management and control capabilities of the production process.

- During the company’s external publicity and visit, the company’s image and professionalism will be improved by explaining the application and advantages of the system for the company.

Extended reading: PID Controller Working Principle

The difference between SCADA, DCS and PLC

SCADA and DCS are a concept, and PLC is a product, the three are not comparable:

- PLC is a product, which can form SCADA, DCS;

- DCS is developed from process control, and PLC is developed from relay-logic control system;

- PLC is equipment, DCS and SCADA are systems.

In a narrow sense, DCS is mainly used for process automation. PLC is mainly used for factory automation (production line). SCADA is mainly used for wide-area needs. Such as oil fields, which stretch for thousands of miles of pipelines.

If they are unified from the perspective of computers and networks, the main reason for the differences lies in the application requirements. DCS often requires advanced control algorithms.

For example, in the oil refining industry, PLC requires high processing speed. Because it is often used in interlocking, even fail-safe systems. SCADA also has some special requirements. Such as vibration monitoring, flow calculation, peak and valley adjustment, and so on.

Therefore, you can simply think:

- SCADA is the dispatch management layer

- DCS is the plant management

- PLC is the field device layer

Sino-Inst offers over controllers for Industrial data recording and analysis.

It is widely used in hydropower, tap water, petroleum, chemical, machinery, hydraulic and other industries to measure, display and control the pressure of fluid media on site.

A wide variety of controllers are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of controllers, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.