How to install the pressure transmitter? This question may be something you need to consider before starting to purchase a pressure transmitter. A clear understanding of the installation requirements and installation methods of pressure transmitters will help in the design and construction of our process systems. And it can better ensure the measurement accuracy of our pressure transmitter.

We, Sino-Inst, are a manufacturer of pressure transmitters. We have provided pressure transmitters and pressure transmitter installation suggestions for process measurement and control in various industries for many years. The installation guide below is a summary of our many years of experience. Hope this can provide you with some help.

Preparation before installation

- The situation of measuring medium: Is the medium that needs to be measured gas, steam or liquid? High temperature or extremely low temperature? Whether there is corrosion, etc.

- Check the equipment: Because the equipment and design suppliers and models are different. Therefore, it is necessary to determine the transmitter corresponding to each tag number based on the measuring range, design and installation method, and the material required by the process medium.

- Determine the installation location: Is it installed on the tank? On the pipeline? Or on the pressure tube?

Various series of pressure transmitters adopt waterproof and dustproof structures and can be installed in any place.

However, it should be considered from the aspects of facilitating daily operation and maintenance, extending service life, and ensuring reliability. The installation location has the following requirements:

- There is sufficient working space around, and the distance from adjacent objects (in any direction) is greater than 0.5m;

- There is no serious corrosive gas around;

- Not subject to surrounding thermal radiation and direct sunlight;

- To prevent interference with the output due to vibration of the transmitter and pressure-guiding tube (capillary tube), the transmitter should be installed in a vibration-free place.

Selection of Pressure Transmitter Installation location

The installation location is also our pressure measuring point.

- The selected pressure measuring point can reflect the actual situation of the measured pressure.

- It should be selected in the pipe section where the measured medium flows in a straight line, and not in the pipeline bends, bifurcations, dead corners or other places where vortices are easy to form.

- When measuring the pressure of a flowing medium, the pressure point should be perpendicular to the flow direction.

- When measuring gas, the pressure point should be above the pipe so that there is no liquid in the pressure pipe.

- When measuring liquid pressure, the pressure point should be at the lower part of the pipe so that there is no gas in the pressure pipe.

- When the transmitter is installed lower than the pressure pipe, the liquid column pressure between the pressure gauge and the pressure pipe should be subtracted.

- When measuring steam pressure, a condensate pipe should be installed to prevent high-temperature steam from directly contacting the pressure measuring element.

Precautions for installing pressure transmitter

- The pressure transmitter should be installed in a place where it is easy to observe and inspect.

- The installation location should be protected from vibration and high temperature.

- Avoid installation in corrosive environments.

- When the measured medium is prone to condensation or freezing, insulation and heating pipelines must be added.

- A stop valve should be installed between the pressure tapping port and the transmitter, and should be close to the pressure tapping port.

- Sealing gaskets and polytetrafluoro tape should be installed at the connection of the pressure transmitter. Generally, asbestos paper or aluminum sheets are used when the temperature is lower than 80℃ and 2Mpa. When the temperature and pressure (50MPa) are higher, annealed copper pads or lead pads are used.

How to install the pressure transmitter

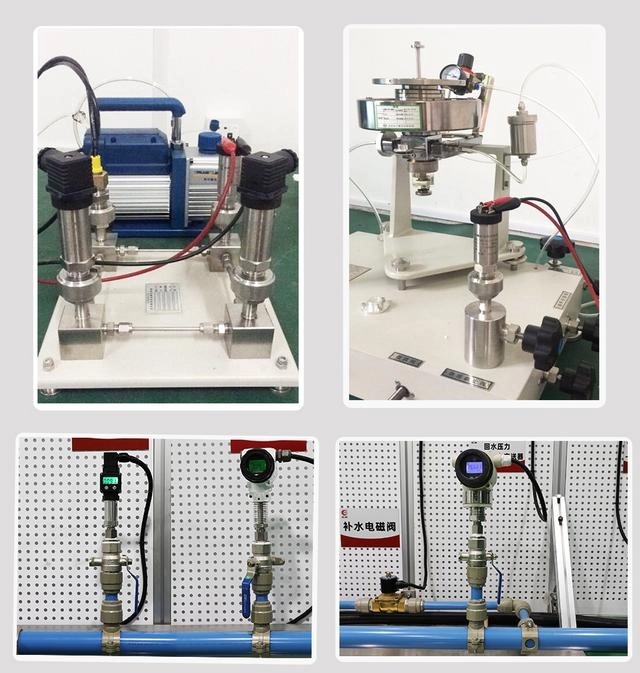

There are many ways to install a pressure transmitter, and the following three are currently commonly used.

⑴Pressure transmitter installation on pipe, this installation method is simple and uses less material.

If it is a high-temperature pipe, you can add 1 or 2 circles of conduit to reduce the temperature.

An isolation valve can also be added to facilitate the later disassembly and replacement of the pressure transmitter.

⑵Flange installation, mainly used for liquid level measurement, using the static pressure of the liquid to measure the liquid level.

⑶ Bracket installation (pipe-mounted flat bracket). Most of them adopt this installation method, which is convenient for installation and maintenance. If it is in an open-air location, an instrument box can be used to protect the pressure transmitter from dust and rain. Of course, our pressure transmitter is well protected, with a protection level of IP65. The working environment temperature is -40~+75℃. Resistant to vibration, dust and rain. Maintenance-free for 5 years.

In addition to the above three, there is also an installation method using a pressure tube, which is also very common.

About pressure transmitter tapping point with impulse tubing

A pressure tap generally refers to taking a small portion of fluid (which may be a gas or liquid) from a process and introducing it to a pressure transmitter to measure the pressure of that fluid. This is a way of directing fluid from a real work process to a measuring device so that it can be monitored or analyzed.

In actual operation, in order to ensure the accuracy of measurement and avoid damage to the pressure transmitter due to fluid characteristics (such as high temperature, corrosiveness, etc.), a specific impulse tubing device or isolation mechanism may be used. These devices cool, filter or otherwise treat the fluid to ensure it is suitable for being measured and to ensure the safety and accuracy of the measuring equipment.

The impulse tube is also a commonly used accessory in the installation of differential pressure transmitters.

Pressure transformer installation with impulse tubing

The pressure transmitter is not installed directly on the pipe, but is connected to the connection joint of the pressure transmitter through an impulse tube with a diameter of 14 mm. The pressure transmitter body is installed next to the device.

When welding this pipe with the impulse tube device (actually a 50-75mm metal pipe) installed on the pipe, the welding angle ends up being about 45°. This will not easily cause dust accumulation. In addition, there is a pipe thread on the head of the metal pipe, which can be tightened with a plug to prevent air leakage. It is easy to open when inspecting the air pipe and check whether there is dust accumulation in the air pipe. The instrument air intake pipe is welded to the upper part of the air intake pipe, which will not easily cause dust accumulation.

The impulse tube of the pressure transmitter should be equipped with 4 instrument valves. If the measured pressure is an air pipe with low pressure, the instrument valve on the upper part of the air pipe can be omitted. This valve is generally called a primary valve, but this valve cannot be omitted when measuring high-pressure gas and water. When the pressure transmitter is working, open the valve at the upper part of the gas intake pipe and the valve at the upper part of the tee, which is generally called the secondary door. Close the lowermost valve, generally called the exhaust valve. Slowly open the valve connected to the pressure transmitter to allow the pressure transmitter to pressurize.

Pressure transmitter wiring

At present, pressure transmitters are more commonly used in DCS control systems. The pressure transmitters installed on site are equipped with 4-20mA output and digital communication functions. Connect to the input of the on-site power room via shielded cable.

For wiring instructions of the pressure transmitter, please refer to: Pressure Transducer Wiring Diagram Guide: 2 Wire-3 Wire-4 Wire

More Pressure Measurement Solutions

What Is Pressure Transducer Output Signal? and Types

Optimize Filtration Monitoring with Differential Pressure Sensors

Low Cost Differential Pressure Sensor – Solve Big Problems!

Oxygen Cleaning Pressure Sensor – No Oil, No Corrosion, No Impurities

Voltage Pressure Transducer Comparison

What Is a Differential Pressure Sensor?

No matter what type of pressure transmitter you plan to purchase or have purchased, you need to consider the Pressure Transmitter Installation. Compact pressure sensor, explosion-proof pressure transmitter, flange-mounted pressure transmitter, or capacitive pressure transmitter, etc.

We at Sino-Inst are professional pressure transmitter manufacturers. If you plan to install a pressure transmitter or are ready to purchase a pressure transmitter and have any questions about the Pressure Transmitter Installation, please feel free to contact our sales engineers!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.