The capacitive fuel level sensor refers to a capacitive liquid level transmitter used to measure the oil level. According to the principle of capacitance sensing, when the height of the measured electrode dips and changes, the capacitance of the measured electrode changes. It can convert the change of oil level into a standard current signal. It is remotely transmitted to the operation control room for the secondary instrument or computer device for centralized display, alarm, or automatic control.

What is a capacitive liquid level sensor?

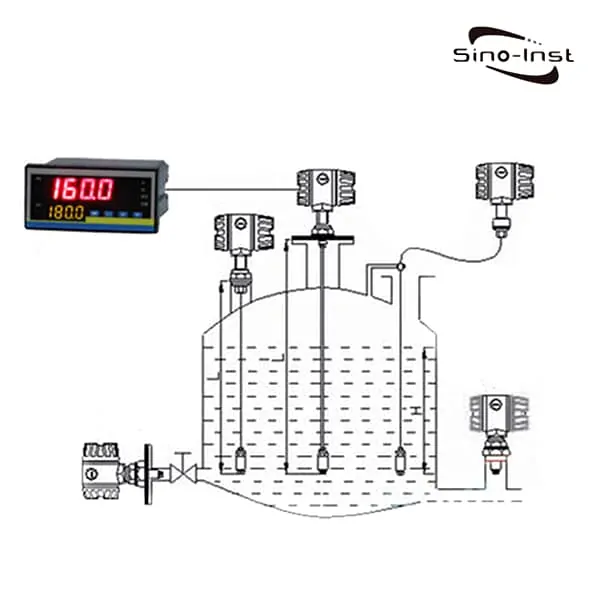

The Capacitive liquid level sensor is based on the principle of capacitance sensing. When the height of the measuring electrode changes by the measured medium, the capacitance changes. It can convert the changes of various material levels and the height of liquid level media into standard current signals, which are remotely transmitted to the operation control room for centralized display, alarm or automatic control by secondary instruments or computer devices. Its good structure and installation method can be applied to high temperature, high pressure, strong corrosion, easy crystallization, anti-blocking, anti-freezing, and solid powder and granular materials.

Capacitive liquid level gauges fundamentally deal with the influence of temperature, humidity, pressure, conductivity of materials and other factors on the measurement process. Therefore, it has extremely high anti-interference and reliability. It can measure strong corrosive liquids, such as acid, alkali, salt, sewage, etc. It can measure high temperature and high pressure medium; process temperature -40~600℃; process pressure -0.1~4.0MPa. A single intelligent integrated capacitive liquid level sensor has two common on-site calibration skills, which provides convenience for users to easily use the product.

Sino-Inst’s capacitive liquid level sensor can measure the liquid level of highly corrosive media and the liquid level of high-temperature media. Measuring the liquid level of a sealed container has nothing to do with the viscosity, density, and working pressure of the medium.

Extended reading: Capacitive water level sensor

Extended reading: Oil-water interface measurement-Magtech magnetic level indicator

Capacitive fuel level sensor working principle

Capacitive fuel level sensor is used to measure the change of capacitance to measure the level of the liquid level.

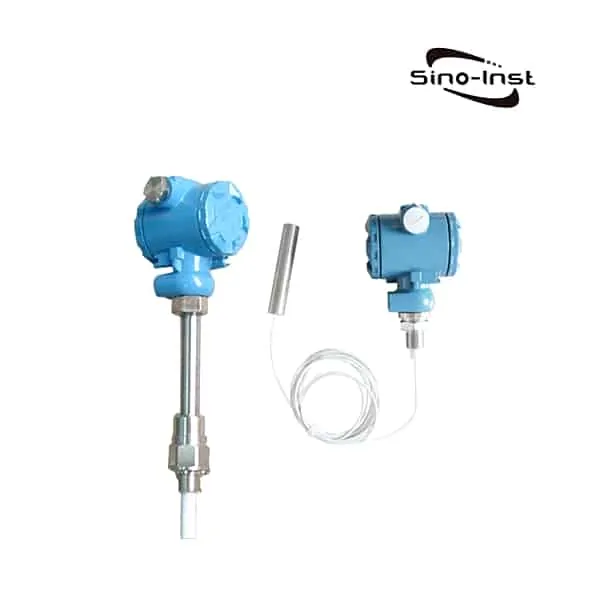

Capacitive fuel level sensor is used to measure the change of capacitance to measure the unevenness of the liquid level. It is a metal rod pierced into the liquid container. The metal rod serves as a pole of the capacitor. The container wall serves as the other pole of the capacitor. The medium between the two electrodes is the liquid and the gas above it.

Because the dielectric constant ε1 of the liquid is different from the dielectric constant ε2 on the liquid surface. For example: ε1>ε2.

Then when the liquid level rises, the total dielectric constant between the two electrodes of the capacitive liquid level gauge increases accordingly, so the capacitance increases.

Conversely, when the liquid level drops, the value of ε decreases, and the capacitance also decreases.

Therefore, the Capacitive fuel level sensor can measure the unevenness of the liquid level by changing the capacitance between the two electrodes.

The sensitivity of the Capacitive fuel level sensor mainly depends on the difference between the two dielectric constants. Moreover, as long as ε1 and ε2 are stable, the liquid level measurement is accurate. Because the measured medium has conductivity. Therefore, the metal rod electrode is covered by an insulating layer. Capacitive fuel level sensor is small in size, and it can easily complete remote transmission and dispatching. Suitable for liquid level measurement of corrosive and high-pressure media.

Extended reading: Oil Level Measurement Solutions for the Oil & Gas Industry

Capacitance level sensor advantages and disadvantages

- Simple structure. There are no movable elastic parts. Therefore, the reliability is relatively high and maintenance is minimal. Under normal circumstances, it is not necessary to carry out regular major, medium and minor repairs.

- Easy to install. The built-in structure especially shows this characteristic. One person, one wrench. It can be installed in ten minutes.

- Easy to adjust. The two potentiometers of zero position and range can perform zero shift or range compression or expansion at will within the effective range of liquid level detection.

- Liquid level detection is basically not affected by changes in process conditions. The buoyancy, differential pressure, and isotope level gauges are all related to the gravity of the medium in the detection. Severe changes in the gas-liquid phase medium will cause additional errors in the test results.

- Wide application range. Aiming at the specific characteristics of the detected object. Specially customized. It can be adapted to liquid level detection under a variety of harsh conditions.

- Low operating cost, no additional impact, no vulnerable, consumable parts, and no additional issues such as depreciation costs for radioactive sources, disposal costs for waste sources, and radiation protection compared with isotope level gauges.

- Lightweight. A high-pressure liquid level gauge that works at 32MPa at the same time weighs less than two kilograms. It is a few tenths of the weight of the high-pressure float level gauge.

Extended Reading: GWR Level Sensor for High Temperature & High Pressure

- This level is not suitable for the detection of highly viscous media, such as molten asphalt.

- The stainless steel process connection part at the lower part of the housing or junction box. It must be reliably connected to the outer wall of the container (grounded). Its contact resistance cannot be greater than 2.

- In normal operation, the probe line cannot have a large swing amplitude in the container. Otherwise, the signal will be unstable.

Extended reading: Diesel fuel tank level gauges & indicators

Capacitive fuel tank level sensor Applications

This series of level gauges have been successfully used in the following occasions:

- Chemical plant: detect the liquid level of chemical raw materials such as polyester, spandex, acid, alkali, etc.

- Environmental protection: detection of sewage level

- Boiler factory: detect the level of the medium in the pressure vessel

- Hydraulic machinery: detection of lubricating oil level

- Food department: check the level of edible oil

- Oilfield: Detect the level of refined oil

Learn more about Diesel fuel tank level gauges & Indicators

Cryogenic Level Sensor for Liquid Nitrogen Tank Level Indicator

The Cryogenic Level Sensor is a capacitance-based level transmitter for cryogenic liquid level measurement. Cryogenic Level Sensor is a customized product for liquid level measurement in low temperature environments such as liquid nitrogen, LNG, and liquid ammonia. Also called liquid nitrogen level sensor. This product has no moving parts and is not disturbed by the external environment. It has the advantages of long-term operation, high sensitivity, good linearity, low temperature resistance, etc. The cryogenic level sensor provides a variety of output signals. It is used in LNG liquid natural gas, petroleum, chemical industry, metallurgy, electric power, papermaking, pharmaceutical and other fields.

Extended reading: liquid nitrogen level measurement

More Featured Fuel Level Sensors

More liquid level measurement solutions

Extended reading: Radar Oil Tank Level Sensor

Sino-Inst is Manufacturer of Capacitive Fuel Level Sensors for oil/fuel/diesel Tank Level Indicator. We supply more than 10 kinds of fuel level measure instruments.

Capacitive Fuel Level Sensors are mainly used for level measurement of Industrial Oil Storage Tanks.

It can measure even for accurate measurement of oil level in car fuel tanks, tankers, oil depots, etc.

Capacitive Fuel Level Sensors enable stable level measurement. This greatly meets the measurement needs of many applications. Can be used from small to large tanks.

Extended reading: ultrasonic level sensor for diesel tank

Sino-Inst’s Capacitive Fuel Level Sensors, made in China, Having good Quality, With better price. Our level measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

The entire team at Sino-Inst’s has received excellent training, so we can ensure that every client’s needs are met. For assistance with your product requirements, whether it’s a Capacitive Fuel Level Sensors, flow sensor, or other device, give us a call.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.