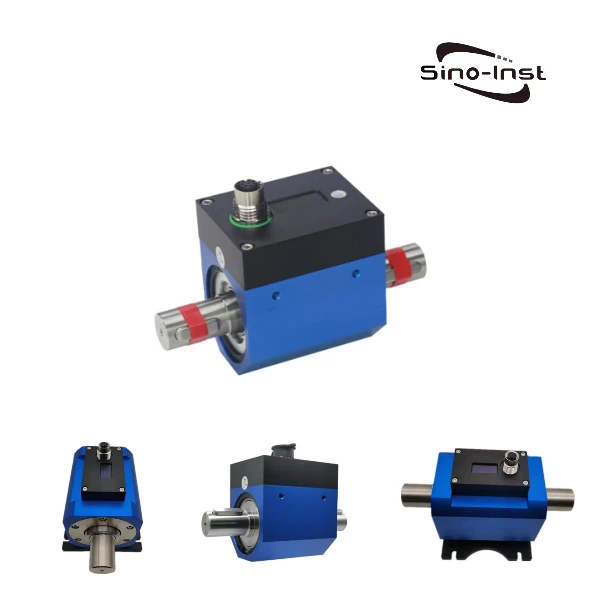

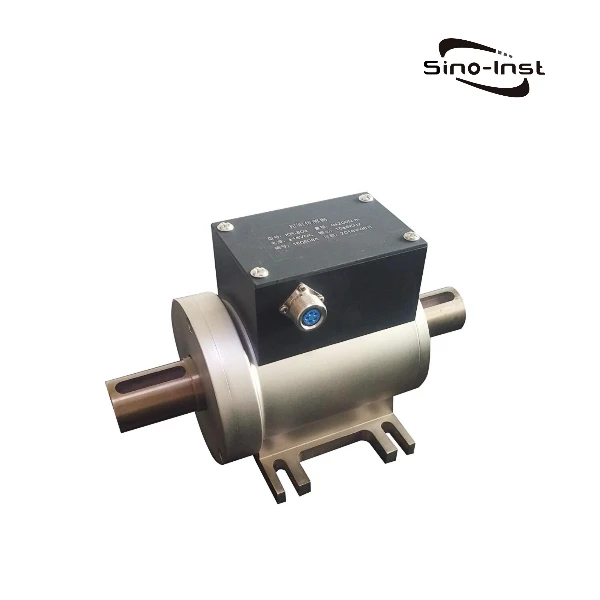

901 Inline Contactless Torque Sensor is a sensor specially developed to transmit torque parameters on the basis of standard torsional strain sensors. Can transmit static torque signal, rotating torque signal, dynamic torque signal, static torque signal. 5 N·m-300000 N·m range is optional.

Features of 901 Inline Contactless Torque Sensor

- It can transmit both static torque signal and rotating torque signal;

- It can transmit both static torque signal and dynamic torque signal;

- High precision and good stability;

- Small size, light weight, easy to install;

- The forward and reverse torque signals can be continuously transmitted without repeated zero adjustment;

- There are no wear parts such as collector rings, which can run at high speed for a long time;

- Strong anti-interference;

- It can be installed in any position and in any direction;

Technical Parameters

| Measuring range : | 0-20、50、100、200、500、1000、2000、5000、10K、20K、50K、100K、150K、200K、300KN.m |

| Output signal: | 0-12v square wave frequency; load current ≥20mA., input power consumption: 110-130mA zero torque: 10 KHZ; Forward full scale: 15 KHZ; Reverse full scale: 5 KHZ |

| Overall Accuracy: | ±0.5%F.S (Linear + Repeatability + Hysteresis) |

| Operating temperature: | 0~+60℃ |

| Temperature Compensation Range: | 20~+60℃ |

| Zero temperature effect: | ±0.1%F.S/10 ℃ |

| Excitation voltage: | 12 VDC |

| Response frequency: | 100μS |

| Insulation resistance: | 2000 MΩ/100VDC |

| Safe Overload: | 120%F.S |

| Material: | alloy steel |

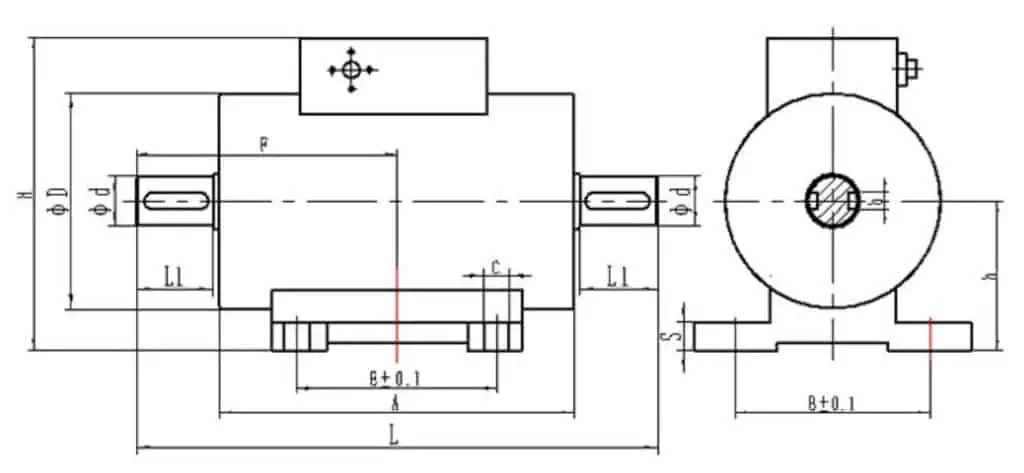

Dimensions

901-5-500N.m

| N.m | φD | φd | L | L1 | E | e | C | A | H | h | B | F | s | Rotational speed (r/min) | self-weight | Key (L*W*H) |

| 5-100 | 78 | 18 | 188 | 28 | 72 | 11 | M8 | 128 | 115 | 54 | 80 | 94 | 10 | 9000 | 3.9 | Single key 23*6*6 |

| 200 | 88 | 28 | 207 | 35 | 72 | 11 | M8 | 133 | 124 | 60 | 80 | 103.5 | 10 | 8000 | 5 | Single key 29*8*7 |

| 500 | 98 | 38 | 240 | 45 | 72 | 11 | M8 | 146 | 142 | 65 | 80 | 120 | 10 | 7000 | 6.1 | Double key 38*10*8 |

901-1000-300KN.m

| N.m | φD | φd | L | L1 | E | A | H | h | B | F | s | c | Rotational speed (r/min) | self-weight | Key (L*W*H) |

| 1000 | 108 | 48 | 275 | 60 | 69 | 149 | 152 | 70 | 90 | 137.5 | 15 | 11 | 6300 | 9.6 | Double key 50*14*9 |

| 2000 | 118 | 55 | 298 | 70 | 69 | 152 | 164 | 77 | 124 | 149 | 15 | 11 | 5600 | 13.7 | Double key 60*16*10 |

| 5000 | 143 | 75 | 356 | 100 | 68 | 150 | 188 | 90 | 146 | 178 | 15 | 13 | 4800 | 22 | Double key 93*20*12 |

| 10000(20000) | 158 | 98 | 388 | 118 | 80 | 146 | 215 | 109 | 170 | 194 | 15 | 13 | 4000 | 34 | Double key 109*28*16 |

| 50000 | 215 | 140 | 451 | 135 | 79 | 171 | 265 | 138 | 170 | 225.5 | 15 | 17 | 2800 | 55 | Double key 123*36*20 |

| 100000 | 247 | 180 | 572 | 180 | 90 | 156 | 305 | 162 | 250 | 261 | 25 | 17 | 2200 | 85 | Double key 166*45*25 |

| 150000 | 350 | 235 | 900 | 315 | 220 | 250 | 420 | 220 | 250 | 450 | 25 | 17 | 2000 | – | Double key 315*56*32 |

| 200000 | 360 | 255 | 900 | 320 | 220 | 210 | 446 | 240 | 250 | 450 | 25 | 17 | 1800 | – | Double key 320*56*32 |

| 300000 | 416 | 295 | 900 | 325 | 220 | 224 | 480 | 250 | 268 | 450 | 25 | 17 | 1800 | – | Double key 325*70*36 |

Learn More About The 901 Inline Contactless Torque Sensor

If you cannot find an answer to your question in our 901 Inline Contactless Torque Sensor, you can always contact us

and we will be with you shortly.

More Featured Torque Sensors For Sale

Sino-Inst is a manufacturer of 901 Inline Contactless Torque Sensor – 5 N·m-300000 N·m. We offer more than 20 types of Inline Contactless Torque Sensors. Inline Contactless Torque Sensors can measure a variety of different mechanical power, rotational speed and torque measuring devices.

Inline Contactless Torque Sensor is also called rotary torque sensor, torque transducer. Mainly used for torque measurement in dynamic situations. The Inline Contactless Torque Sensor is equipped with a speed measuring device, which can measure the rotational speed while measuring the torque. At this time, the Inline Contactless Torque Sensors can also be called a torque speed sensor.

Sino-Inst’s Inline Contactless Torque Sensors, made in China, have good quality, with better prices. Our Inline Contactless Torque Sensors are widely used in China, India, Pakistan, USA and other countries.

Sino-Inst’s entire team is well trained, so we can ensure that each customer’s needs are met. If you need any help with your product requirements, whether it is a Inline Contactless Torque Sensor, level sensors, or other equipment, please give us a call .

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

901 Inline Contactless Torque Sensor- 5 N·m-300000 N·m

901 Inline Contactless Torque Sensor is a sensor specially developed to transmit torque parameters on the basis of standard torsional strain sensors. Can transmit static torque signal, rotating torque signal, dynamic torque signal, static torque signal. 5 N·m-300000 N·m range is optional.

Product SKU: 901 Inline Contactless Torque Sensor - 5 N·m-300000 N·m

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 1500

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5