Electronic Pressure Switches are pressure switches with digital display.

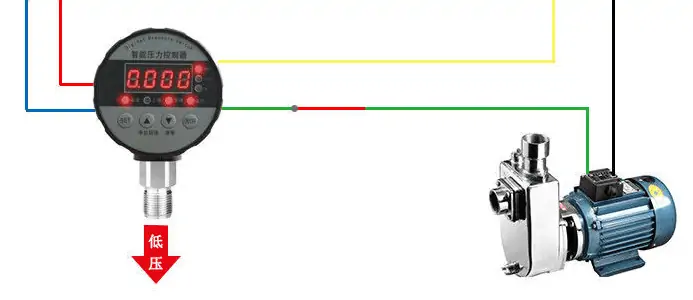

Electronic pressure switches have electronic pressure sensors instead of mechanical pressure sensors. Electronic pressure switch integrates pressure measurement, display, output and control. The non-electricity is directly converted into voltage or current through the pressure sensor. The sensor signal is processed. Finally, it is input to the microcontroller to drive the rear circuit or control the electrical switch. The user can determine the pressure value for the action of the pressure switch.

Sino-Inst offers a variety of Pressure Switches for pressure control. If you have any questions, please contact our sales engineers.

Features of Electronic Pressure Switch YX-18

- Multi-channel switch (with load capacity 1.2A), analog signal 4~20mA optional;

- The pressure control switch point adjustment has no dead zone and can be set arbitrarily within the range;

- Delay switching output time can be set by yourself;

- Key-press adjustment and on-site setting of various parameters, easy to operate and more flexible.

Specifications of Electronic Pressure Switch YX-18

| Working parameters | Model | ||

| YX18-X | YX18-B | YX18-F | |

| Connection method | G1/4(Can be customized) | M20*1.5(Can be customized) | M20*1.5(Can be customized) |

| Output function | Two switches + one analog | Two switches + one analog | Four switching + one analog |

| voltage | External power supply: 24VDC±15% | External power supply: 24VDC±15%, ripple ≤±5%; 220VAC±15% (optional) | |

| Contact rating | DC 24V—1.2A (resistive) | DC 24V—1A (resistive); AC 250V—3A (resistive) | |

| control precision | ≤±0.5%FS | ||

| Control range | -0.1~0~0.003~60MPa | ||

| Overload capacity | 150% | ||

| Switch times | 1×107 | ||

| Protection level | IP65 | ||

| Conditions of Use |

Medium temperature: -30℃~85℃; Ambient temperature: -20℃~70℃; Relative humidity: 5~85%; storage temperature: -40℃~85℃ |

||

Electronic Pressure Switch Applications

From gas mechanics to hydraulic field, precision control field, pressure automatic control field. Electronic pressure switches can replace most of mechanical pressure switches, liquid level switches, pressure relays, electric contact pressure gauges and are used in some places.

Electronic Pressure Switch for Air Compressor

Pressure switches are often used in paper machines, air compressors or pump sets. In this type of equipment, we rely on pressure switches as safety devices, alarms or control elements in the system.

Take an air compressor (referred to as “air compressor”) as an example:

An ordinary air compressor consists of three main parts: a motor, a V-type air pump and an air storage tank. The air compressor is equipped with a pressure switch, which can adjust the start and stop of the motor. By adjusting the pressure in the oil tank, the air compressor can rest .

The air compressor factory can set a certain start and stop pressure according to the requirements of different customers during the debugging process. For example, when the compressor starts, air is pumped inside.

When the pressure reaches the set value, the pressure switch will contact the contacts to stop the motor. When the pressure is lower than the set value, the air compressor starts again. Keep the pressure in the oil tank within the pressure range.

Advantages of Electronic Pressure Switch

- Display accuracy

Intelligent pressure switch: 0.3%FS, 0.5%FS, 1%FS, 1.5%FS

Mechanical pressure switch: panel display - Repeatability error

Intelligent pressure switch: less than or equal to 0.5%FS

Mechanical pressure switch: less than or equal to 1%FS, less than or equal to 1.5%FS - Shock resistance

Intelligent pressure switch: good shock resistance

Mechanical pressure switch: relatively poor shock resistance because it is filled with oil - Setting operation

Intelligent pressure switch: power on, the zero pressure state can be operated by pressing the button, the setting range is the full range

Mechanical pressure switch: need to be pressurized to the specified pressure, set with a screwdriver, setting range: 20%-80%FS - Contact type

Intelligent pressure switch: PNP, NPN/solid state relay; this type of contact will not produce arcing, contact carbon deposits, etc.

Mechanical pressure switch: micro switch, will oxidize

Extended reading: Miniature Pressure Switch

Disadvantages of Electronic Pressure Switch

The advantages of the intelligent pressure switch are mentioned above, and the disadvantages of the smart pressure switch are mainly complicated in wiring. 4 or more, need power supply to use. There may be interference when encountering strong electricity.

More Featured Pressure Switches

You may like:

- SMART HART Pressure Transmitter

- Pressure Transducers for Air Conditioning & Refrigeration

- Analog Pressure Transducers vs Digital Pressure Transducers | How to Choose?

- Vacuum Pressure Transducers | Product List and FAQs

- What Is Psi in Pressure Sensor?

- What Is a Hydraulic Pressure Transducer? and Product List

- Pressure Transmitter Installation Guide

- What Is Pressure Transducer Output Signal? and Types

- Optimize Filtration Monitoring with Differential Pressure Sensors

- Low Cost Differential Pressure Sensor – Solve Big Problems!

- Oxygen Cleaning Pressure Sensor – No Oil, No Corrosion, No Impurities

Sino-Inst offers over 10 Electronic Pressure Switches for pressure measurement. About 50% of these are liquid pressure swithces, 40% is gas pressure switches.

It is widely used in hydropower, tap water, petroleum, chemical, machinery, hydraulic and other industries to measure, display and control the pressure of fluid media on site.

A wide variety of Electronic Pressure Switches options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Electronic Pressure Switch instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

Electronic Pressure Switch for Sale | Digital display

Electronic Pressure Switches are pressure switches with digital display.

Product SKU: Electronic Pressure Switch YX-18

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 100

Price Valid Until: 2059-09-30

Product In-Stock: InStock

5