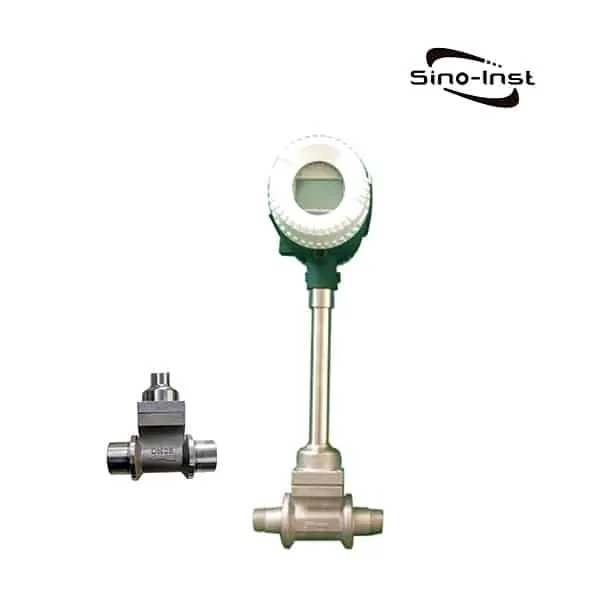

DP Flow Meter includes throttling parts (eg. orifice plates), differential pressure transmitters, three-way valves. Used for flow measurement of various liquids, gases and steam.

Integral DP Flow Meter installs the throttle, differential pressure transmitter, three-way valve and accessories on the short process pipe. It is supplied as a whole after calibration. Reduce installation errors. Shorten installation man-hours. There is no need to connect additional pressure measuring points and temperature measuring points to make the output signal. Automatically realize temperature and pressure compensation to improve measurement accuracy.

Sino-Inst, Manufacturer for differential pressure flow meters. Including the Orifice plate, Venturi, Annubar, etc. Suitable for liquid, gas, and steam flow measurement. Please contact our sales engineers for technical support!

Features of Integral DP Flow Meter

a. Measurement accuracy:

Because the integrated differential pressure flowmeter does not require a pressure pipe, the phenomenon of differential pressure distortion is reduced. It has higher accuracy than the split differential pressure flowmeter. For differential pressure flow meters that require real flow calibration. Because it is the flow calibration of the whole device. So the system accuracy can be improved by 0.3%.

b. Simple installation

The integrated differential pressure flowmeter only needs to be flanged or directly welded to the phenomenon pipeline. And directly lead to the current signal of the differential pressure transmitter. There is no need to lay additional pressure pipelines and install differential pressure transmitters.

Used to measure the flow of gas or steam. Due to the optional multi-parameter differential pressure transmitter. It can automatically monitor temperature and pressure changes and automatically trim the output signal. So there is no need to install additional temperature and pressure measuring elements. Greatly improve the installation progress.

c. Wide range ratio

The integrated differential pressure flowmeter with multi-parameter differential pressure transmitter is equipped with dynamic algorithm compensation. So the turndown ratio is greatly improved. The large range can reach 8:1.

d. Low purchase, installation and operating costs

The integrated differential pressure flowmeter does not need to lay additional pressure pipeline. And there is no need to heat the impulse pipeline. Therefore, the installation cost is greatly saved. Adapt to the severe cold area in winter or occasions requiring heat preservation.

For the integrated differential pressure flowmeter with multi-parameter differential pressure transmitter, it integrates temperature and pressure compensation. Therefore, the purchase cost of pressure and temperature transmitters is eliminated. Greatly reduce the cost of purchasing and installation.

e. Variety of forms

Because the primary element can use different forms of throttling devices. Therefore, as long as the appropriate integrated differential flowmeter is selected for various operating conditions. It can realize the accurate flow of any kind of complicated working conditions.

Extended reading: [Working principle&Price]SI3051ANB Annubar Flow Meter

Integral DP Flow Meter Specification

| Pipe diameter (mm) | DN50-DN1000 optional |

| Measured medium | Single-phase fluid such as liquid, gas, steam (or can be considered as single-phase fluid) |

| temperature range | -40℃~450℃ |

| Pressure range | 2.5MPa (4.0MPa) |

| Throttle | Preferred fixed-value ISA1932 nozzles (the preferred serial number β20 for fixed-value aperture is 0.52 and 0.72), fixed-value orifice plate (the preferred serial number β20 for fixed-value aperture is 0.34, 0.52 and 0.72) |

| Pressure method | Angle joint pressure or flange pressure |

| Differential pressure transmitter | PMD230, 1151, 3051CD, 3095CD, EJA110A |

| Range | 3:1, 6:1, 10:1, 10:1 or more |

| System uncertainty | ±1.0%, ±1.5%, ±2.0%, ±2.5% (The accuracy of the system is affected by many factors. Our company can provide you with relevant consulting services) |

| Throttle material | 1Cr18Ni9Ti, SUS316, others |

| Material of clamp | 1Cr18Ni9Ti, SUS316, 20# steel, others |

| Power supply | Transmitter part 24VDC (20mA) Flow display equipment: 220VAC, 50Hz 24VDC |

| Explosion proof | iaⅡcCT2-T5 intrinsically safe explosion-proof |

| Transmitter output signal | 4-20mA (communication connection requires a minimum load resistance of 250W) |

| Protection level | IP65 |

| Allow vibration acceleration | £1.0g |

| Ambient temperature | -20℃~55℃ (please declare if it exceeds this range) |

| environment humidity | 45%~85% |

| Atmospheric pressure | 86~106kPa |

DP Flow Meter Working Principle

The fluid filled with the pipe flows through the throttling device in the pipe, and the stream will form a local contraction at the throttling part. As a result, the flow velocity will increase and the static pressure will decrease. So a static pressure difference (or differential pressure) is generated before and after the throttling part.

The greater the flow rate of the fluid, the greater the differential pressure generated before and after the throttle. Therefore, the flow can be measured by measuring the differential pressure.

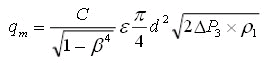

Knowing the relevant parameters. According to the principle of flow continuity and Bernoulli equation, the relationship between the differential pressure and the flow rate can be derived1 to obtain the flow rate. The basic formula is as follows:

c——outflow coefficient dimensionless

d——The diameter of the orifice or throat of the throttle under working conditions m

D——Inner diameter of upstream pipe under working conditions m

qm——mass flow kg/s

qv——Volume flow m3/s

β-diameter ratio d/D dimensionless

ρ——The density of the fluid kg/m3

ε——Expansibility coefficient dimensionless

Extended Reading: Differential Pressure (DP) Flow Meters Technology

The Engineers Guide to DP Flow Measurement

What is DP Flow Meter?

The differential pressure flowmeter is an instrument for measuring flow. It uses the principle that there is a certain relationship between the pressure difference and the flow rate generated when the fluid flows through the throttling device. The flow rate is measured by measuring the pressure difference.

The throttling device is a local constriction element installed in the pipeline. The most commonly used are perforated plates, nozzles and venturi tubes.

How is DP flow calculated?

Flow calculation formula 1: The conversion of the relationship between the differential pressure and the flow rate of the differential pressure flowmeter

The differential pressure of a differential pressure flowmeter is proportional to the square of the flow rate. In other words, the flow rate is proportional to the square root of the differential pressure. It is expressed by the following formula:

The scale unit of the flow meter is the flow percentage. The lower limit of the differential pressure is 0 o’clock.

In the above formula:

△P is any differential pressure;

Q is any flow;

△Pmax is the upper limit of differential pressure;

Qmax is the upper limit of the flow rate;

n is any percentage of flow

Flow calculation formula 2: Conversion of volume flow in standard state and working state

The conversion formula of volume flow between standard state and working state is as follows:

In the formula, qv is the volumetric flow rate under working conditions, in m3/h;

qn is the volume flow under standard conditions, in m3/h;

P is the absolute pressure under working conditions, the unit is Pa;

Pn is the absolute pressure in the standard state, in Pa;

T is the thermodynamic temperature under working conditions, in K;

Tn is the thermodynamic temperature in the standard state, in K;

Z is the gas compression coefficient under working conditions;

Zn is the gas compressibility coefficient under standard conditions;

Flow calculation formula 3: Calculation of changing range from standard orifice plate

Sometimes it is encountered in the field that the measured flow exceeds the maximum range of the orifice plate. Or the flow rate is too small and can only be displayed below 30% of the maximum range. The emergency can be met by expanding or reducing the differential pressure range.

The basis for changing the range is the formula. The maximum differential pressure and maximum flow rate of the flowmeter in use are known. With these two parameters combined with the flow calculation formula, the calculation work for changing the range can be carried out.

Tools:

Difference between integrated DP flow meter and general DP flowmeter

A general differential pressure flow meter includes two parts: a throttle and a differential pressure transmitter. The installation requires a pressure pipe system to connect the two.

The integrated differential pressure flowmeter directly assembles the throttling piece, the pressure pipe system and the differential pressure transmitter. At the same time, the integrated differential pressure flowmeter depends on the product. It can have both pressure and temperature measurement functions, temperature-pressure compensation functions, etc., all integrated in one device.

DP Flow Meter Straight Run Requirement

The accuracy of flow measurement has a lot to do with whether the installation of the differential pressure flowmeter meets the requirements. The general requirements are as follows:

When installing, it must be ensured that the opening of the throttling piece is concentric with the pipe. The end face of the throttling piece is perpendicular to the axis of the pipe.

There must be a certain length of straight pipe section upstream and downstream of the throttle.

- Orifice flowmeter requires 10D front and 5D rear

- V-cone flowmeter requires 5D in the front and 1-3D in the back

- The elbow flowmeter is installed on the elbow.

What Is Integral Orifice Plate?

The main function of the orifice is to reduce the pressure of the fluid. But it does not mean that it can be mixed, and the orifice plate should be selected according to the specific medium.

The integrated orifice flowmeter is a high turndown differential pressure flow device composed of a standard orifice plate and a multi-parameter differential pressure transmitter (or differential pressure transmitter, temperature transmitter and pressure transmitter). It can measure the flow of gas, steam, liquid and natural gas. It is widely used in process control and measurement in the fields of petroleum, chemical industry, metallurgy, electric power, heating, water supply and so on.

The integrated orifice device is simpler. No pressure tube is required. It can be directly connected to differential pressure transmitter and pressure transmitter.

Extended reading: Vortex Steam Flow Meter

Orifice Plate Flow Meter

Orifice plate flow meter works together with an orifice plate, differential pressure transmitter, with Differential Pressure Measurement principle. Easy installation. Orifice plate flow meters can be used with gases, liquids, corrosive, and high temperature fluids. Orifice flow meters can measure steam, gas, liquids, and many industrial areas. Applications include steam flow, boiler feedwater, and fluid flow rates in building water lines. Read more about: Condensate Flow Meter-Steam Condensate Flow Meter|Types & Selection Guide

Frequently

Asked

Questions

More Featured Flow Meters

Sino-Inst offers Integral DP Flow Meters.

A wide variety of Integral DP Flow Meter options are available to you, such as brass, carbon steel. You can also choose from free samples.

Sino-Inst is Integral DP Flow Meter supplier.Integral DP Flow Meter products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, including 375 with ISO9001, ISO14001, and Other certification.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.