Venturi flow meter is also called classical venturi, and is used to call venturi meter, standard venturi. It is used to measure the flow of single-phase stable fluid in closed pipelines.

Venturi flow meter is a flow measurement method based on the principle of differential pressure. Commonly used to measure the flow of fluids such as air, natural gas, coal gas, and water. In the standard throttling device, the upstream and downstream straight pipe sections required by it are short. The lasting pressure loss is small, the performance is stable, and the maintenance is convenient.

Sino-Inst, Manufacturer for differential pressure flow meters. Including the Orifice plate, Venturi, Annubar, etc. Suitable for liquid, gas, and steam flow measurement. Please contact our sales engineers for technical support!

Features of Venturi flow meter

- Less head loss than an orifice or nozzle meter, due to the streamlined design

- Ideal for clear gas, liquid or steam applications

- Available in many materials and end arrangements

- Can be equipped with fittings to accept secondary instrumentation packages

The classic venturi tube is simple, durable and stable in performance.

Classic venturi pressure loss is small, saving the energy needed for fluid delivery.

Classic venturi tube in the range of 50 ~ 1200.

No real-flow calibration is required.

Beyond this range, you can refer to the design and manufacture.

When high precision is required, real-time calibration is possible.

The body is installed in long size, and it is not convenient for transportation and installation for large-diameter instruments.

What is a venturi flow meter?

Venturi flowmeter, also known as venturi tube flow meter. It is a commonly used device for measuring the flow of pressurized pipelines.

It is a differential pressure flowmeter, and is commonly used to measure the flow of air, natural gas, gas, water, and other fluids.

It consists of a “contraction section”, a “throat” and a “diffusion section”, which are installed on the pipe where the flow rate needs to be measured.

The classic venturi tube is designed and manufactured, according to China GB/T2624-93, and is verified according to the verification procedure JJG640-94.

In the standard throttling device, it requires the shortest upstream and downstream straight pipes, the lowest pressure loss, stable performance, and convenient maintenance.

Because of its accurate calculation and low energy consumption, it has been widely used in petroleum, chemical, electric power, and metallurgy industries.

Venturi flow meter parameters:

1. Nominal diameter: 50mm≤DN≤1200mm (more than this range needs to be calibrated)

Roughcasting shrinkage section: 100mm ≤ DN ≤800mm

Mechanical processing shrinkage section: 50mm ≤ DN ≤ 250mm

Shrinking section of rough welded iron plate: 200mm≤DN≤1200mm

2. Throttle aperture ratio β: 0.3 ≤ β ≤ 0.75

Roughcast shrinkage segment: 0.3 ≤ β ≤ 0.75

Machining shrinkage section: 0.4 ≤ β ≤ 0.75

Coarse section of rough welded iron plate: 0.4≤β≤0.7

3. Reynolds number range: 2 × 10 5 ≤ ReD ≤ 2 × 10 6

Rough cast shrinkage section: 2 × 10 5 ≤ ReD ≤ 2 × 10 6

Machining shrinkage section: 2 × 10 5 ≤ ReD ≤ 2 × 10 6

Shrinkage section of rough welded iron plate: 2×10 5≤ReD≤2×10 6

4. Accuracy level: 1

Venturi Flow Meter PDF

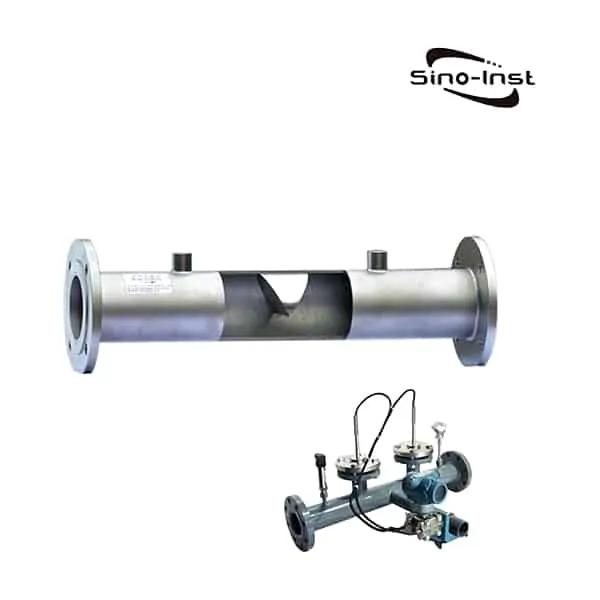

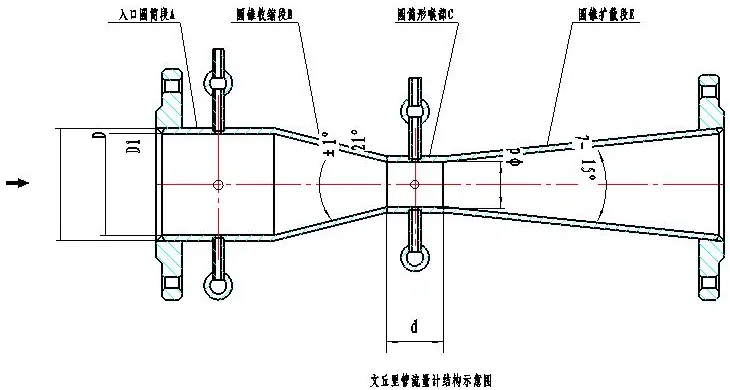

Classic venturi flowmeter structure

The axial section of the classic venturi is shown in the figure above.

It is composed of an inlet cylinder section A, a conical contraction section B, a cylindrical throat C, and a conical diffusion section E.

The diameter of the cylinder section A is D, the length is equal to D. The contraction section B is conical and has an angle of 21 ° ± 1 °. The throat C is a cylindrical shape of diameter d, the length of which is equal to d;

E is conical and has a diffusion angle of 7° to 15°.

The constricted section of the classic venturi is divided into three forms: a coarse cast shrinkage section, a machined shrinkage section, and a coarse welded iron plate shrinkage section.

The upper-pressure port and the throat pressure port of the classic venturi, are made into several (not less than four) separate tube wall pressure ports.

And several separate tube walls are pressure-connected by a pressure-equalizing ring.

When d≥33.3mm, the diameter of the throat pressure port is 4~10mm, the diameter of the upstream pressure port should be no more than 0.1D. When d≤33.3mm, the diameter of the throat pressure port is 0.1d~0.13d. The diameter of the upstream pressure tap is 0.1d to 0.1D.

Extended reading: How to realize the flow accumulation function in PLC?

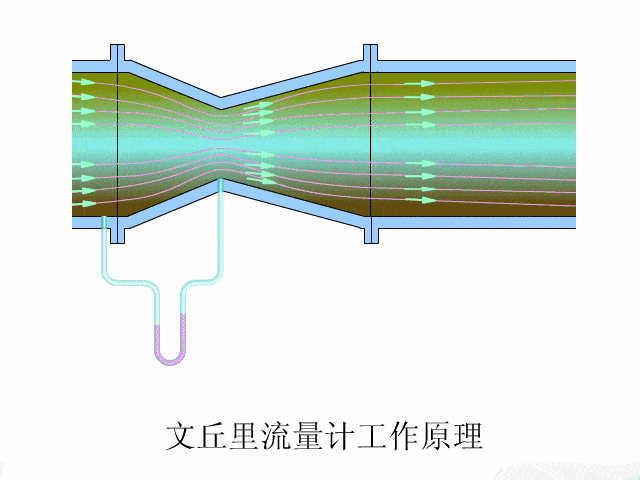

Venturi meter working principle

The Venturi flow meter produces a differential pressure, to calculate the flow rate through a pipe.

The meter works by measuring the pressure of fluid before and after it passes through a narrow tube; the pressure difference indicates the volumetric rate of flow.

The basic measurement principle of the new generation, of differential pressure flow measuring instruments, is the flow measurement method based on the law of conservation of energy – the primary effort equation and the flow continuity equation.

The inner venturi consists of a circular measuring tube, and a special core placed in the measuring tube and coaxial with the measuring tube.

The outer surface of the special core has a geometric profile, similar to the inner surface of a classic venturi. And forms a different diameter annular flow gap with the inner surface of the measuring tube.

How does a Venturi meter work?

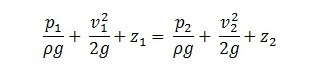

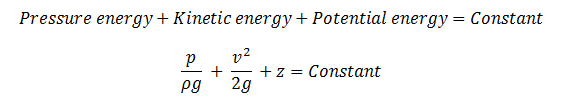

The working of venturi meter is based on the principle of Bernoulli’s equation.

Bernoulli’s Statement:

It states that in a steady, ideal flow of an incompressible fluid, the total energy at any point of the fluid is constant.

The total energy consists of pressure energy, kinetic energy, and potential energy or datum energy.

Mathematically:

Here all the energies are taken per unit weight of the fluid.

The Bernoulli’s equation for the fluid passing through the section 1 and 2 are given by

Flow tools:

Venturi Flow Meter Applications

Since its development, venturi products have been successfully applied to the measurement of high-humidity natural gas, low-pressure dirty biogas, coke oven gas, gas, steam, hot water, high-temperature hot kerosene, etc., And the practical application range is rapidly expanding.

Besides, the venturi tube has a unique measurement advantage, for measuring conditions such as long straight pipe installation conditions, special high temperature, high pressure, strong corrosive and dirty media, and non-single phase flow measurement.

Of course, in the sewage and wastewater treatment industry, in addition to venturi flowmeters, electromagnetic flowmeters are also the first consideration for many users.

For example, if you need to measure the flow of wastewater in a 2-inch pipe. Then you can refer to: Magnetic Flow Meters Guides.

Extended reading: Flow Nozzle for Steam Flow Measurement

Orifice meter vs Venturi meter

The orifice flow meter is a flowmeter with a variable cross-sectional pressure difference.

The velocity at the vein is the largest, the pressure of the fluid is minimized, the structure is simple, but the resistance loss is large.

The Venturi flow meter is also a flowmeter with a variable cross-section pressure difference.

On the basis of the orifice flowmeter, the orifice plate is replaced by a lengthy and gradually expanding short tube, and the structure is simple, the resistance loss is small, but the cost is high.

The orifice flowmeter is similar to the venturi flowmeter, in terms of working principle. But some of the main differences are that the orifice plate can be easily replaced. Adapting to a wide range of different flow rates, while the venturi’s throat diameter is fixed.

The measured flow rate range is limited by the actual pressure difference.

Due to the vortex on the downstream side of the orifice plate, the permanent loss of the orifice flowmeter is large. And the structural shape of the venturi flowmeter can avoid the formation of vortices.

Thus, permanent losses can be greatly reduced.

Venturi flowmeters consume much less energy in measuring flow than orifice flowmeters.

But because venturi flowmeters are more time consuming and expensive than orifice flowmeters, in manufacturing and processing.

Orifice flowmeters is the least troublesome when installing the pipeline and the lowest cost.

In fluid measurement, venturi flowmeters are typically used for the measurement of gas flow at low flow rates.

The orifice flow coefficient in orifice flowmeters is significantly affected by fluid disturbances, which are generated upstream of the orifice plate.

The influence of valves, elbows and other fittings.

The value of its flow coefficient is less affected by downstream disturbances.

Typically, such flow meters should be installed at 50 and 10 pipes diameters, from the upstream and downstream disturbance components, respectively.

It is obvious that the required distance is related to the nature of the disturbance.

Therefore, when measuring with an orifice flowmeter, the orifice flowmeter must be properly installed according to the disturbance of the fluid.

Through the specific analysis and comparison of the orifice flowmeter and the venturi flowmeter, the advantages and disadvantages between them can be seen. And the user is reminded to analyze and compare more when selecting the flowmeter.

In this way, you can choose the measurement tools you need.

Extended reading: [Working principle&Price]SI3051ANB Annubar Flow Meter

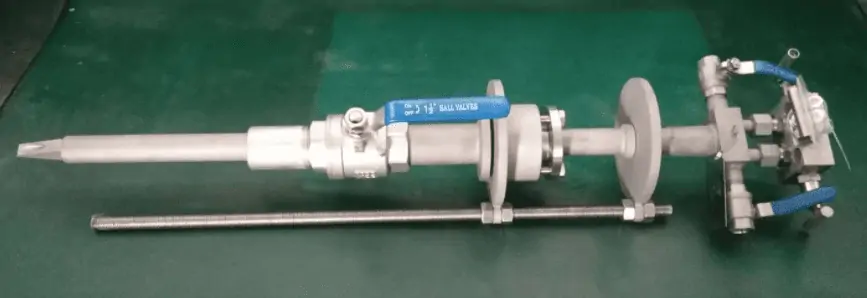

Pitot Tube vs Venturi Meter

Pitot tube flowmeter is a new type of advanced insertion type differential pressure flowmeter. It is designed and manufactured according to the standard of IS03966 “Measurement of Fluid Flow in Closed Pipeline – Velocity Area Method Using Pitot Tube Static Pressure Tube”.

To meet the different measurement requirements of different field conditions, Pitot tube flow sensors are divided into standard and functional structures.

The standard type is suitable for the measurement of pure gas, steam, liquid and various chemical materials and liquids. The function is suitable for the working conditions of easy blockage, adhesion, high impurity content, and solid-liquid mixed flow such as various coal gas in the metallurgical industry. Measurement of gas, steam and various liquids.

Smart Pitoba flowmeter is easy to scale and easy to install. Just make a hole in the pipeline. Insert the Smart Pitoba into the center of the pipeline. Connect it with the pipeline by welding or flange.

The difference between Pitot tube vs venturi meter, in simple terms:

- Pitto is taking advantage of the same point.

The only difference between the total pressure and the static pressure is the dynamic pressure V2/2g to obtain the speed and flow. - The Venturi nozzle is used to pass through two points of variable diameter.

The measured pressure difference is the dynamic pressure increase (or static pressure decrease).

List the continuity equation with the product of diameter and velocity.

Then find the speed and flow.

Frequently

Asked

Questions

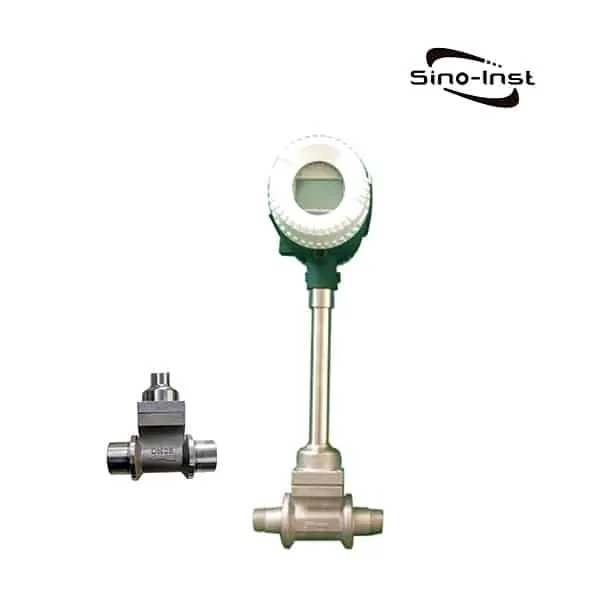

Related Products

Related Blogs

Sino-Inst, China, supplies all kinds of Flow Meters. Provide professional flow measurement solutions.

Sino-Inst offers over 50 flow meter products. About 50% of these are differential pressure flow meters (like the Orifice flowmeter), 40% are Magnetic Flow Meters, and 40% are Thermal mass flowmeters.

A wide variety of Annubar flow meter options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of flow measurement instrumentation, located in China.

The top supplying country is China (Mainland), which supply 100% of the turbine flow meter respectively. Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.