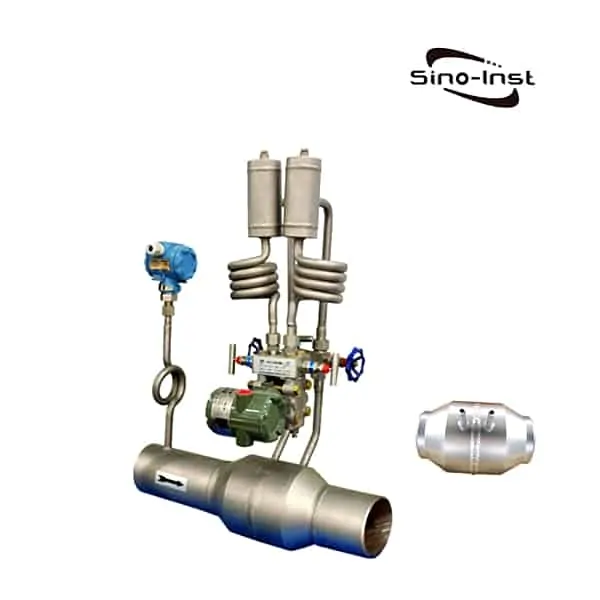

Annubar flow meter also known as flute-shaped constant velocity tube flow meter and Toba tube flow meter. Annubar flow meter is a differential pressure flow meter.

Annubar Flow Meter is a no-equal solution with a patented, averaging pitot tube that delivers superior measurement accuracy over a wide flow range. This flow meter can measure multiple variables and is engineered with an integrated thermowell for temperature measurement. Its patented T-shaped sensor is capable of obtaining measurements via a single pipe penetration while maintaining a small profile in the pipe to reduce permanent pressure loss and increase energy savings.

Sino-Inst, Manufacturer for differential pressure flow meters. Including the Orifice plate, Venturi, Annubar, etc. Suitable for liquid, gas, and steam flow measurement. Please contact our sales engineers for technical support!

Features of SI 3051ANB Annubar Flow Meter

- Honeycomb hexagonal stable structure,increasing the range ratio.

- Suitable for square or rectangular pipes.

- For the unavoidable clogging problem of similar products in measuring dirty media, achieve non-stop production maintenance.

- Average speed tube + three valve group + temperature pressure compensation + transmitter, form an integrated structure, easy to use.

- No flow coefficient drift, long-term stability.

- Exclusively provide intuitive resonance check to ensure long-term stable operation.

- Low pressure loss, low energy consumption, significant energy saving effect.

- Easy to install and save labor, low price and fast delivery (1 week)

Annubar Flow Meters’ technical parameters

- Suitable for measuring the flow of liquids, gases, and steam.

- The maximum working temperature of 1300 ° C (with appropriate materials and mounting parts).

- The highest working pressure up to 400Bar (40MPa)

- The highest viscosity is 500 cp

- The length of the upstream and downstream straight pipe sections is required to be short.

- Standard stainless steel grade.

- Long-term accuracy is not affected by wear and tear.

- Specifications: DN50-DN5000 (mm); insert: DN500-DN5000 (mm);

- Measurement accuracy: ±6.0%; repeatability: ±0.1%;

- Range:

- volume flow: 10:1;

- mass flow: 8:1;4,

- working pressure: the average speed tube does not propose a functional type: ≤ 20MPa;

- the average speed tube can be proposed type: ≤ 10MPa;

- Fluid temperature: ≤ 450 ° C; Medium viscosity: ≤ 30CP (equivalent to heavy oil);

- Material:

- Average speed tube, three valve group: various grades of stainless steel (optional);

- Main pipe, flange: stainless steel or carbon steel (optional);

Application of the Annubar flow meter

The output of the Annubar flowmeter is a differential pressure signal.

It can be used with instruments that measure differential pressure to accurately measure a variety of liquids, gases and vapors (superheated steam and saturated steam) in the He-shaped pipe and rectangular pipe.

The size of the pipe to be tested ranges from 20MM to 5000MM. Annubar has been successfully used in the chemical industry, (including the nuclear industry) chemical industry, petrochemical industry and metal smelting industry.

It is suitable for:

- Gas delivery and liquid delivery

- Energy research, steam boiler heat rate, pump efficiency.

- Gas compressor efficiency and fuel consumption

- Process control: input and output, ratio, balance; cooling water or air, steam heating.

- Feeding in the chemical industry

The Use and Characteristics of the Annubar flowmeter

The Annubar flowmeter is an ideal substitute for differential pressure fow measurement. Because of its simple installation, low-pressure loss, high strength, no wear and no leakage.

It can be widely used in industrial and mining enterprises to measure the flow of blast furnace gas, compressed air, steam and other liquids and gases.

1. The unique internal secondary average structure provides high precision (±1% reading), and high repeatability (±0.1%).

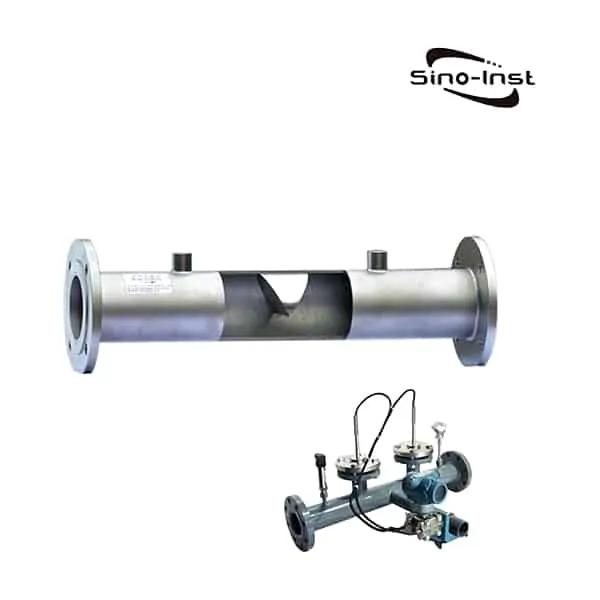

2. The outer impact tube of the Annubar flowmeter, is processed by a single piece of material without welding.

It has the highest strength, compared with similar products welded by the double-body structure. And it is also convenient to use high-temperature resistance and corrosion resistant material.

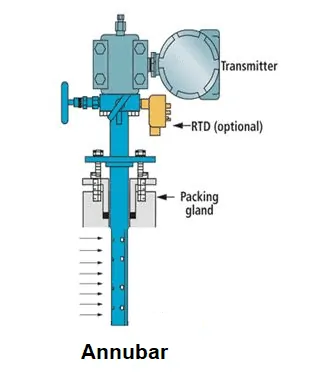

Working principle of Annubar flow meter

When the fluid flows through the probe, a high-pressure distribution zone is created at the front. And the pressure in the high-pressure distribution zone is slightly higher than the static pressure of the pipeline.

According to the Bernoulli equation, the velocity of the fluid flowing through the probe is increased. And a low pressure distribution zone is generated at the rear of the probe.

The pressure in the low-pressure distribution zone is slightly lower, than the static pressure of the pipeline.

The fluid flows from the probe and creates a partial vacuum, at the back of the probe with vortices on either side of the probe.

The cross-sectional shape of the constant velocity flow probe, the rough surface condition and the position of the low-pressure tapping orifice are key factors, in determining probe performance.

The stability and accuracy of the low voltage signal, is decisive for the accuracy and performance of the uniform velocity probe.

The Annubar average velocity probe detects the average differential pressure, produced by the average velocity of the fluid.

The Annubar average velocity probe has multiple pairs of pressure tapping holes, arranged in a certain standard in the high and low-pressure zones, making it possible to accurately measure the average flow rate.

Annubar Flow Meter Calculation

The flow calculation formula of the uniform velocity tube flowmeter is derived from the Bernoulli equation and the continuity equation:

Qv=α﹒ ε﹒ (π/4)﹒ D2﹒ (2P/ρ1)0.5

Qm=α﹒ ε﹒ (π/4)﹒ D2﹒ (2?P﹒ρ1)0.5

Among them: Qv: volume flow

Qm: mass flow

α: Sensor structure coefficient

△P: Differential pressure value

ε: fluid expansion coefficient

ρ: Density under fluid conditions

ε: fluid expansion coefficient

For incompressible fluid ε=1, for compressible body ε<1. If D, △P, and ρ1 in the formula all use SI units, the unit of QV is M3∕S. The unit of Qm is ㎏∕S.

How Averaging Pitot Tubes Work-Annubar Technology

Video source: https://www.youtube.com/embed/ofiQPZkGPJM?rel=0

Advantages and Disadvantages of the Annubar flowmeter:

Advantages:

- Can be inserted through a small opening.

- Can be used to sample the velocity at several points.

- Reasonable design, easy installation, and economy

- Low-pressure drop, minimal obstruction.

- High accuracy and good stability

Disadvantages:

- Single point measurement.

- The pitot tube is fragile

- DP signal is low.

Annubar flow meter calibration

The annubar flowmeter is a commonly used type of flowmeter. It is a new type of differential pressure flow detection component, developed based on the principle of pitot tube velocity measurement.

It has the advantages of stable performance, flexible use and high reliability.

1. Connect the signal cable and power cable;

2, open the import and export valves, the inlet and outlet valves must be consistent

3. Open the stainless steel three-valve balance valve, slowly open the high-low pressure end of the orifice plate, and close the stainless steel three-valve balance valve, after the fluid passes through the flowmeter.

Annubar flowmeter installation pipeline conditions:

(1) The straight pipe sections before and after the throttle piece must be straight, and must not be visible to the naked eye.

(2) The straight pipe section used for installing the throttle piece should be smooth. If it is not smooth, the flow coefficient should be multiplied by the roughness correction sparse.

(3) In order to ensure the flow of the fluid, a fully developed turbulent velocity distribution is formed in the 1D before the throttle. And the distribution is made into a uniform axisymmetric shape, so:

1). The straight pipe section must be round. And the roundness of the 2D range of the throttle is very strict and has a certain roundness index.

Specific measurement method:

(A) On the OD, D/2, D, 2D 4 vertical pipe sections of the throttle, measure the inner diameter of the four pipes, at least equal to each other with an equal angular distance, and take the average value D.

The difference between the measured value of internal diameter, and the average value shall not exceed ±0.3%.

(B) After the throttle element, 8 inner diameter single measured values are measured, by the above method at the OD and 2D positions. And any single measured value is compared with D. And the large deviation of zui must not exceed ±2%.

2). Before and after the throttle element, a straight pipe section of sufficient length is required.

The length of the straight pipe section which is long enough. And the form of the local resistance part. Before the throttle element are related to the diameter ratio β.

(4) The length of the straight pipe section between the upstream side of the throttle member, the resistance member and the second resistance member may be 1/2 of the listed value. According to the form of the second resistance member, and β = 0.7 (regardless of the actual β value)

(5) When the upstream side of the throttle member is an open space, or a large container with a diameter ≥ 2D, the open space or the straight pipe length, between the large container and the throttle member shall not be less than 30D (15D).

If there are other local resistance members, between the throttle member and the open space or the large container. The open space is from the open space to the length of the small straight pipe section 1 provided, between the throttle member and the local resistance member.

The total length of the straight pipe section between the throttle pieces shall not be less than 30D (15D).

You may like:

Frequently

Asked

Questions

Sino-Inst offers over 10 Annubar Flow Meter products. These are differential pressure flow meters, 40% are water meters (like the Insertion Turbine Flow Meter), and 40% are water treatment (like the Annubar flow meter ).

A wide variety of Annubar Flow Meter options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Annubar Flow Meter, located in China. The top supplying country is China (Mainland), which supply 100% of the Annubar Flow Meter respectively.

Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide. Annubar Flow Meter products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.