The target flow meter is also known as the drag force flow meter. Insert a target (drag element) into the flow field. Measure the drag force on the inserted target and convert it to the flow velocity.

The target flow meter is also called a drag force flowmeter. The target flow meter inserts a target (drag element) into the flow field. The target usually is a flat disc or a sphere with an extension rod. There will be a differential pressure. And then target flow meters measure the drag force on the inserted target and convert it to the flow rate. Sino-Inst manufactures target flow meters for liquid, gas, and steam measurement.

Sino-Inst, Manufacturer for differential pressure flow meters. Including the Orifice plate, Venturi, Annubar, etc. Suitable for liquid, gas, and steam flow measurement. Please contact our sales engineers for technical support!

Target Flow Meter Definition

Sino-Inst offers a Capacitive target flowmeter. A capacitive target flowmeter is a new type of capacitive force inductive flowmeter. Developed on the basis of traditional target flowmeter. And developed with new sensors and microelectronic technology. It has both orifice plate and vortex flowmeters.

The characteristics of no moving parts. High sensitivity, accuracy comparable to volumetric flow meters, and a wide range. The use of a chip-level capacitive force sensor and an efficient anti-overload structure design are the key cores for the new product to achieve high precision and high stability.

In addition, it has unique anti-interference and anti-impurity performance. Our capacitive target flow meters can replace the conventional flow measurement. It has good adaptability to difficult flow measurement conditions. Such as high viscosity, dirty media, easy to set and block, high temperature, low temperature, and strong corrosion.

It is widely used in petroleum, chemical industry, metallurgy, power. Pharmaceutical, environmental protection, food and other fields.

The target flow meters are applicable to the following ranges:

- Diameter ,Φ15~Φ2000mm or bigger.

- High and low temperature, -196°C~+450°C.

- High pressure : 0~42Mpa.

- Suitable for various media: gas, liquid (including high viscosity liquid, slurry), steam;

- It is suitable for low-velocity media, and its minimum measurable flow rate is 0.08m / s.

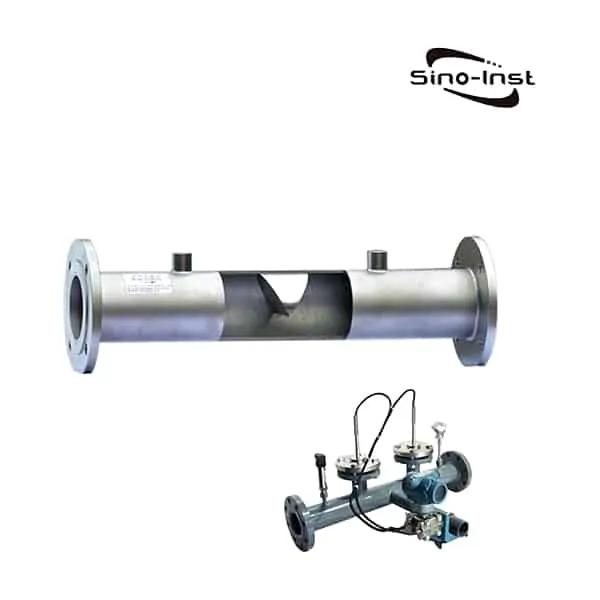

Target Flow Meter Construction

The capacitive target flowmeter is mainly composed of a measuring tube (housing), a new capacitor.

It consists of a force sensor, chokes, integrated display, and output.

Features of Target Flow Meters

- The whole instrument has a solid structure without moving parts, easy to disassemble.

- Can choose a variety of anti-corrosion. And high and low temperature resistant materials (such as Hastelloy, titanium, etc.);

- The whole machine can be made fully sealed without dead corners (welded form). Without any leakage points, and can withstand 42MPa high pressure;

- Small pressure loss, only about 1/2 △ P of standard orifice plate;

- Strong anti-interference and anti-impurity capabilities;

- The instrument has a self-checking program. And the failure phenomenon is clear at a glance;

- The sensor is not in contact with the measured medium, there is no component wear, and it is safe and reliable to use;

- Dry calibration method can be used in situ, that is, weight hanging method. One-button operation can complete the calibration;

- There are multiple installation methods to choose from. Such as online plug-in, low installation costs;

- With integrated temperature and pressure compensation, direct output quality or standard square;

- Optional small signal removal, non-linear correction, and filtering time can be selected;

- It can accurately measure the gas and liquid flow under various normal temperature. High temperature 500 degrees, and low temperature -200 degrees;

- Accurate measurement, accuracy can reach 0.2%;

- Good repeatability, generally 0.05% to 0.08%, fast measurement;

- Can change the range of resistance (target) according to actual needs;

- Low-power battery on-site display, can directly read the displayed value online. And the display can read the instantaneous and cumulative flow and percentage bar graph at the same time;

- Simple and convenient installation and extremely easy maintenance;

- Multiple output formats, which can transmit various parameters remotely;

- Strong vibration resistance, pulsating flow can be measured within a certain range.

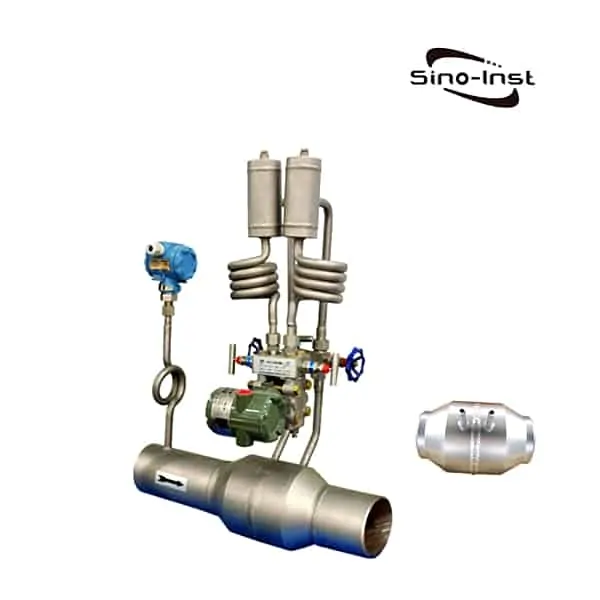

Target flow meters types

Plug-in target flowmeter Pipeline (flange) target flowmeter Wafer type target flowmeter Clamp type (sanitary) target type flowmeter Jacketed thermal target flowmeter Threaded target flowmeter

Technical Data of Target Flow Meter

| Item | Target flowmeter Performance, Parameters |

| Medium | Liquid, Gas, and Steam |

| Caliber | Pipe type 15~300mm Clamp type 15~600mm Plug type100~2000mm |

| Pressure | 0.6~10MPa 0.6~42MPa 0.6~42MPa |

| Accuracy | ± 0.2 ~ ± 1.5%FS |

| Medium Temperature | -196° C~+450° C ( Confirming the temperature range before purchase) |

| Media temperature | -20 ~ +70 (normal temperature type) -196 ~ +700 (high/low temperature type) |

| Precision | ± 0.2% ± 0.5% ± 1.0% ± 1.5% ± 2.5% |

| Range | 1: 3 1: 5 1: 10 1: 10 1: 10(Steam) |

| Compensation | Temperature compensation; Pressure compensation |

| Repeatability | 0.1%~0.08% |

| Power Supply | 3.6V lithium battery, 24V DC |

| Output | LCD display, and 4~20mA, 0~10V, impulse or RS485 (Optional) |

| Material of measure tube | Carbon Steel; 304; 316L; Being able to provide other according to user requests |

| Explosion- Prevent Symbol | ExiallCT4, ExiallBT4 |

| Protection Rank | IP65; IP67 |

| Features | * Installation is simple and convenient, easy to maintain * A variety of output forms, spread far and wide variety of parameters * Anti-vibration is strong, within a certain range can be measured pulsatile flow * Anti-jamming, anti-contamination ability to exceptionally strong |

Advantages of Target flow meters:

- They are useful for difficult measurements. Such as slurries, polymer bearing and sediment-bearing materials corrosive mixtures, etc.

- They provide good accuracy when calibrated for specific streams.

- They are good for relatively high temperatures and pressures.

- Low initial set up cost

- Can be used with a wide variety of fluids, even viscous fluids and slurries.

- Can be used in abrasive, contaminated, or corrosive fluid flow

- Can be made to measure flow velocity that is sporadic or multi-directional with sphere drag element designs

- Can be used for any type of liquid, gas, or steam cryogenics.

- There is no moving parts such as bearings, to wear out causing failures.

- High reliability where life tests have been made to 20,000,000 cycles.

- Can be used for any line size from 0.5 inches and up with any type of mounting.

- Range/fluid changes accomplished by simply changing targets.

- Turndowns aprox.15:1

- Several materials are available. Among them 303/304 SS, 316 SS, hastelloy and inconel.

Disadvantages of target flow meters:

- Calibration must be verified in the field.

- Pressure drop is inevitable due to the rod and the drag element

- In-line mounting required in these flowmeters.

- They have a limited calibration data.

- In case of target flowmeters no-flow conditions must exist for zeroing

Target Flow Meters Applications

Gas: gas, air, hydrogen, natural gas, nitrogen, liquefied petroleum gas, hydrogen peroxide, flue gas, methane, butane, chlorine, etc.

Liquid: heavy oil, paraffin, asphalt, sulfuric acid, cooking oil, residue oil, acetone, diesel, mine water, detergent, soy sauce, gasoline, silicone oil,

Syrup, solvent, perfume, seawater, aviation kerosene, soap ketone, glucose, canola acid, saltwater, paste, ink, coolant,

Glycol, mineral oil, liquid sugar, hydrochloric acid, automotive coatings, resin, butter, vegetable oil, liquid oxygen, shampoo, toothpaste, gel,

Fuel, milk, bleach, conditioner, soda, additives, cleaning agents, alkaline, ammonia, marine oil, chemical reagents, kerosene,

Glycerin, dye, water, nitric acid, high boiling point organic solution, lard, alcohol, oil, ethylene, polypropylene, methyl benzyl, etc.

Steam: Superheated steam, saturated steam.

Extended reading: Vortex Steam Flow Meter

Application Cautions for Target Flowmeters

- Be careful when operating target flowmeters low in their flow range. Because accuracy can be compromised at these flow rates.

- Avoid abrasive fluids. Because the target can be damaged and measure inaccurately.

- Fluids that coat the target can cause it to become heavy. Such that the force measurement can become inaccurate and unresponsive to flow changes.

- These flowmeters should not be applied to slurries and high viscosity liquids.

- Calibration is an important part of ensuring accurate operation of target flowmeters.

- Pressure effects, physical effects, and flowmeter orientation can affect the zero adjustment of target flowmeters.

- After calibrating the target flowmeter (typically with weights), be sure to zero target flowmeters after installation with a full pipe under no flow conditions. To ensure compensation for these effects in the final installation.

- This procedure also compensates for the calibration shift that can occur when the orientation of the flowmeter during calibration is different than its installed orientation.

- In general, in-situ zero adjustment should be performed after re-installing target flowmeters.

- Operating a target flowmeter above its maximum flow rate can cause the calibration to shift and potentially damage the suspension system of the flowmeter.

- Note also that operating target flowmeters continuously for extended periods of time can cause a mechanical shift to occur that can affect the zero. Because the target may not return to exactly the same position after being exposed to forces over time.

- Rapidly changing flow, such as slug flow conditions, two-phase flow, and start-up conditions (gas to liquid transitions). Can similarly affect the mechanics of the target flowmeter and hence its zero. Therefore, it is advisable to periodically verify the zero adjustment of target flowmeters.

Target Flow Meter Working

When the medium flows in the measuring tube, the pressure difference caused by its own kinetic energy passing through the blocking member (target). And has a force on the blocking member. The magnitude of the force is proportional to the square of the velocity of the medium.

The mathematical way is as follows:

F = CdAρ • V2 / 2

In the formula: F —— the force of the choke (kg)

Cd-object resistance coefficient

A ——Axial projection area of the choke on the measuring tube (mm2)

ρ ——Density of medium under working conditions (kg / m3)

v-average flow velocity of the medium in the measuring tube (m / s)

The force F received by the choke member (target) is transmitted to the capacitive force sensor via a rigidly connected transmission member (stem).

And the capacitive force sensor generates a voltage signal output:

V = KF

In the formula:

V——Voltage output by the capacitive force sensor (mV), K——Proportional constant, F——The acting force of the choke (target)

So, after the voltage signal is pre-amplified, AD converted. And processed by the computer. The corresponding instantaneous flow and cumulative total can be obtained.

How Target Flowmeters Work

Target flowmeters measure flow by measuring the amount of force exerted by the flowing fluid on a target suspended in the flow stream.

The force exerted on the target by the flow is proportional to the pressure drop across the target.

Like differential pressure flowmeters. Bernoulli’s equation states that the pressure drop across the target (and hence the force exerted on the target) is proportional to the square of the flow rate.

Using this relationship, 10 percent of full scale flow produces only 1 percent of the full scale force.

At 10 percent of full scale flow, the target flowmeter accuracy is dependent upon the transmitter being accurate over a 100:1 range of force.

Transmitter accuracy is typically degraded measuring low forces in its range, so flowmeter accuracy can be similarly degraded.

So, this non-linear relationship can have a detrimental effect on the accuracy and turndown of target flowmeters.

Remember that of interest is the accuracy of the flow measurement system — not the accuracy of the transmitter.

How to Use Target Flowmeters

- Target flowmeters inferentially measure the flow of liquids and gases. Such as water, air, industrial gases, and chemicals.

- Be careful using target flowmeters on fluids that can coat the target. Because the flowmeter accuracy can be degraded.

- This flowmeter can be applied to sanitary, cryogenic liquids, relatively clean, and corrosive liquids.

- Thematerials of construction of all wetted parts, including the flowmeter body and seals, should be considered.

- Inline target flowmeters are available up to approximately 6 inches in size.

- Insertion target flowmeters are available for larger line sizes.

- Applications requiring sanitary piping systems are often found in the pharmaceutical and chemical industries. Such as in the manufacture of drugs and vitamins.

- Sanitary applications are especially prevalent in the food and beverages industry where cleanliness is important.

- Applications for target flowmeters are found in the mining, mineral processing, pulp and paper, power, petroleum, chemical, and petrochemical industries.

- Common applications include the measurement of process and cooling water flows.

More Technical Support

How does a turbine flow meter work?

How does a vortex flowmeter work?

What does a Coriolis meter measure?

You may like:

Frequently

Asked

Questions

Sino-Inst offers over 10 target flow meters for flow measurement. About 50% of these are liquid flow meters, 40% is the gas flow sensor and 20% are steam flow meter.

A wide variety of flow meters options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Target flow measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.