When you need to measure oil flow, do you also encounter a problem: Turbine Flow meter Vs Gear Flow meter? How to choose?

Turbine flow meters and gear flow meters are commonly used flow meters. Although there is only one word difference literally, there are still different essential differences between the two.

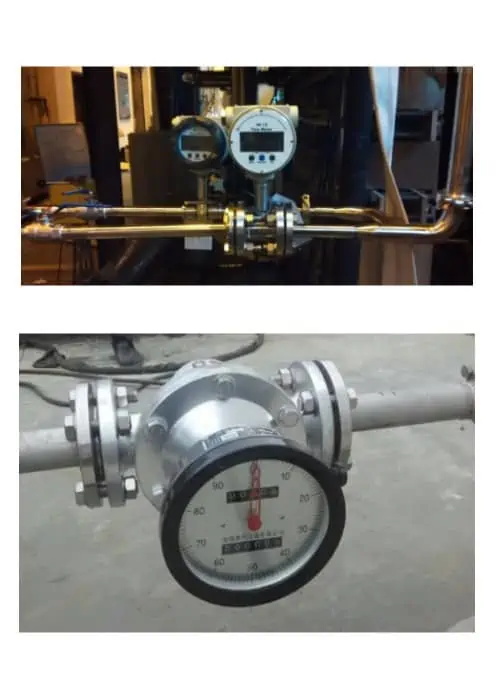

Turbine Flow meter

Turbine flow meters are velocity flow meters, also called impeller flow meters. Can be used to measure the instantaneous flow and cumulative flow of liquids and gases.

Turbine flowmeters are widely used in flow measurement: petroleum, organic liquids, inorganic liquids, liquefied gas, natural gas, coal gas and cryogenic fluids. Turbine flowmeter signals can be divided into pulse signals or current signals (4-20mA). It is suitable for use with secondary display, PLC, DCS and other computer control systems.

Know more about: Turbine type Flow Meter for Liquid & Gas technology

Gear Flow meter

Oval gear flowmeter is a precision instrument used to measure liquid flow. It is a direct reading cumulative meter. It is a positive displacement flow meter that measures the sum of the liquid flow through the pipeline.

The oval gear flowmeter can choose two counting mechanisms: mechanical display meter and electronic display meter. The display meter has the functions of displaying cumulative flow, instantaneous flow, and zero return. It can realize on-site display and remote control.

For different measuring media (acid, alkali, organic liquid, oil, food, etc.), the flowmeter can be made of different materials (cast steel, stainless steel, and 316). It is suitable for flow measurement in chemical, petroleum, pharmaceutical, electric power, metallurgy, and food industries. Extended reading: Cylinder Gear flow meter for micro flow measurement.

Read more about Everything You Need To Know About Electronic Flow Meters

Let’s sort it out for everyone:

Turbine Flow meter Vs Gear Flow meter

1. Different measurement principles:

The liquid turbine flowmeter is a velocity flowmeter. The accuracy is 0.5%, which can be improved to 0.2%. The material of the watch body is generally stainless steel. According to site requirements, explosion-proof products can be made.

Oval gear flowmeter is a positive displacement flowmeter. The accuracy is 0.5%. Oval gear flowmeter is a purely mechanical mechanism. When the rotor of the flowmeter rotates, it drives the rotation of the counter to generate a cumulative total. Oval gear flowmeters are especially popular on occasions where explosion-proof requirements are relatively high.

2. Requirements of the working pressure:

The working pressure of the oval gear flowmeter is generally not large, 1.6Mpa. Using cast steel material, it can reach 2.5Mpa.

In contrast, turbine flowmeters are easier to make into high-pressure products. The maximum pressure of the high-pressure turbine flowmeter can reach over 25Mpa.

Requirements for low working pressure:

Turbine flowmeter does not have much requirement for the low working pressure in the pipeline, basically, it can be measured when the medium flows through it.

However, oval gear flow meters have higher requirements for small working pressures. Because of the different calibers, the pressure required to push the flowmeter rotor to work is different. The small working pressure required from small diameter to large diameter is between 0.3~0.8Mpa.

Extended reading: Positive displacement flow meter working principle

3. The influence of working temperature:

The maximum working temperature of the turbine flowmeter is 120°C. The maximum working temperature of the oval gear flowmeter is 160℃.

4. The difference of applicable media:

Water, solvents, light oils, etc. can be well suited for liquid turbine flow meters, but media with too high viscosity are not suitable.

The elliptical gear flowmeter is generally suitable for oily media. The viscosity of the applicable medium is higher than that of the turbine flowmeter. The greater the viscosity of the medium, the higher the accuracy.

For some corrosive media, both types of flowmeters can partially measure.

But the stainless steel oval gear flowmeter is not cost-effective. And for water and some electrolyte solutions, oval gear flow meters cannot be used. Because the internal mechanical parts are easily damaged by water.

Extended reading: Turbine flow meter Applications

Turbine Flow Meter Application Case: Demineralized Water.

5. Requirements on the installation site:

As a positive displacement flowmeter, the elliptical gear flowmeter has relatively low requirements for the straight pipe sections before and after and basically has no requirements for straight pipe sections.

The turbine flowmeter, as a velocity flowmeter, has higher requirements for the front and rear straight pipe sections. Especially for some small diameter turbine flowmeters, a corresponding straight pipe section must be matched.

Extended reading: Turbine Insertion Flow Meter for Large Diameter Pipeline

6. The difference between display and signal output:

The mechanical meter head of the oval gear flowmeter displays the cumulative amount. To display the instantaneous flow, you need to output a signal, and the matching secondary instrument displays the instantaneous flow value.

Turbine flowmeter can display instantaneous flow and accumulated flow on-site, and can also output with the remote signal.

7. The problem of maintaining accuracy:

The accuracy of turbine flow meters and oval gear flow meters cannot be maintained for a long time. In order to maintain the accuracy of the flowmeter, it must be calibrated regularly.

You may need to measure the flow of lubricating oil, diesel, fuel, hydraulic oil, etc.

Combine the above points and your requirements. You should be able to decide which flow meter to choose. If you still have technical questions, please contact our sales engineers in time.

Extended reading:

What is the K-factor in a flow meter?

Cryogenic Flow Meters|Liquid Nitrogen-Liquid Oxygen-LNG fluids

Turbine Flow Meter Specification

| Product Name: | Liquid Turbine Flowmeter |

| Measuring medium: | water, oil, alcohol and other liquids (viscosity <5×10-6M2/S) |

| Diameter range: | DN4~DN200 (DN4~80 commonly used thread connection) |

| Accuracy class: | ±1%R; ±0.5%R; ±0.2%R (special customization) |

| Output signal: | square wave pulse (voltage type), 4-20MA, 0-5V (intelligent type) |

| Operating environment: | -20℃~+60℃; 5%~90%RH |

| Connection method: | external/internal thread, flange, clamp |

| Communication method: | RS485 communication MODBUS-RTU (intelligent type) |

| Body material: | stainless steel 1CR18NI9TI, 316L (hygienic type) |

| Protection class: | IP65 (ordinary type); IP68 (special custom) |

Turbine Flow meter Vs Gear Flow meter working principle

About the working principle of Turbine Flow meter Vs Gear Flow meter. I think the following video provides a good explanation. let’s look at it together:

Turbine Flow Meter Advantages and Disadvantages

Advantages:

- High precision. Generally up to ±1%R, ±0.5%R.

- Output pulse frequency signal. It is suitable for total measurement and connection with computer. No zero drift, strong anti-interference ability.

- The structure is compact and lightweight. Easy installation and maintenance. Great flow capacity.

- Good repeatability, short-term repeatability can reach 0.05~0.2%. It is because of good repeatability. Frequent calibration or in-line calibration results in extremely high accuracy.

- There are many types of special sensors. It can be specially designed according to user needs. Such as: low temperature type, bidirectional, downhole type, special type for sand mixing, etc.

- The pressure compensation can be performed under the stable pressure state of the measured gas.

- The range is wide, the medium and large diameters can reach 1:20, and the small diameters are 1:10.

Disadvantages:

- Regular calibration is required. There is no way to maintain accuracy for long periods of time. Cannot work continuously for a long time.

- Higher requirements for the cleanliness of the medium. But filters can be installed.

- The flowmeter is greatly affected by the flow velocity distribution of the incoming flow (a flow regulator can be installed).

- It is not suitable for places where the flow rate changes rapidly.

- Not suitable for testing corrosive media.

Turbine Type Flow Meter Installation Guidelines

In order to ensure the accurate measurement of the turbine flowmeter, the installation location and method must be selected correctly.

- Requirements for straight pipe sections:

- The flowmeter must be installed horizontally on the pipeline (the inclination of the pipeline is within 50), the axis of the flowmeter should be concentric with the axis of the pipeline during installation, and the flow direction should be consistent.

- The length of the upstream pipeline of the flowmeter should have an equal diameter straight pipe section of not less than 2D. If the installation site is allowed, it is recommended that the upstream straight pipe section is 20D and the downstream is 5D.

- Requirements for piping:

The inner diameter of the upstream and downstream piping at the installation point of the flowmeter is the same as the inner diameter of the flowmeter. - Requirements for bypass pipes:

In order to ensure that the normal use of the medium is not affected during the maintenance of the flowmeter, a cut-off valve (stop valve) should be installed on the front and rear pipelines of the flowmeter, and a bypass pipeline should be set at the same time. The flow control valve should be installed downstream of the flowmeter. When the flowmeter is used, the shut-off valve installed upstream must be fully opened to avoid unstable flow of the fluid in the upstream part. - Requirements for the external environment:

The turbine flowmeter is best installed indoors. When it must be installed outdoors, sun protection, rain protection and lightning protection measures must be adopted to avoid affecting the service life. - Requirements for impurities contained in the medium:

In order to ensure the service life of the flowmeter, a filter should be installed before the straight pipe section of the flowmeter. - Installation site:

The flowmeter should be installed in a place that is easy to maintain and free from strong electromagnetic interference and heat radiation - Requirements for installation and welding:

The user can configure a pair of standard flanges to be welded on the front and rear pipes. Welding with flow meter is not allowed!

Before installing the flowmeter, the welding slag and other dirt in the pipeline should be strictly removed. To ensure that the flowmeter is not damaged during use.

Frequently

Asked

Questions

More Flow Measurement Solutions

This article “Turbine Flow meter Vs Gear Flow meter”, Sino-Inst provides you. Please indicate the source!

Sino-Inst, Manufacturer for Turbine Flow meter & Gear Flowmeters, like gas turbine flow meter, liquid turbine flow meter, sanitary turbine flow meter, insertion turbine flow meter, steam turbine flow meter, and natural gas turbine flow meter.

Sino-Inst’s Turbine Flow meter & Gear Flow meter, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.