Ideally, we should be able to use a liquid volume sensor to directly measure the volume of the liquid in the container. Well, but in fact, there is no mature liquid volume sensor product on the market.

Because there are various shapes of liquid containers. Such as cylinders, spheres, rectangles, cylinders and squares with hemispherical ends.

So why are we talking about liquid volume sensor here? Don’t worry, we don’t have a mature liquid volume sensor. However, we have A dozen ways for liquid level measurement, with different level sensors. Combined with Sino-Inst’s volume recorder. It can collect, display and convert the liquid level of various regular and irregular tanks in the industrial field into the corresponding tank volume. It is suitable for monitoring, controlling and collecting various process parameters.

Featured Level Sensors

Level Measurement Technologies

Liquid Volume Sensor

So far there is no sensor that can measure the volume of liquid. Because there are various shapes of liquid containers, such as cylinders, spheres, rectangles, cylinders and squares with hemispherical ends.

The height of the liquid in these containers can be detected by a variety of sensors. According to the shape of the container, the volume and weight of the liquid in the container can be calculated.

Extended Reading: Advantages and disadvantages of laser level transmitter

For rectangles, cylinders or squares, the volume and weight of the liquid can be calculated directly by multiplying the floor area of the container by the height of the liquid. And the corresponding relationship is linear. The hemispherical cylinder and sphere at both ends can be calculated by definite integral. The law of curvature change is the volume formula of the function. Calculate the volume and weight of the liquid according to the height of the liquid.

Monitoring liquid volume solutions

Most of our liquid level sensors can output liquid level signals, such as 4-20mA signal, 0-10V signal, RS485 and so on.

However, the liquid level transmitter alone cannot calculate the liquid volume of tanks of different sizes. It’s too complicated. A separate recorder is required to calculate it.

Therefore, the digital display volume meter can collect, display and convert the liquid level of various regular and irregular tanks in the industrial field into the corresponding tank volume. It is suitable for monitoring, controlling and collecting various process parameters.

So, How to measure volume of liquid?

After the liquid level gauge is installed in your tank, Sino-Inst’s volume display controller/recorder can collect, display and convert the liquid level of various regular and irregular tanks on the industrial site into the volume of the corresponding tank . It is suitable for monitoring, controlling and collecting various process parameters.

The volume meter is equipped with volume download software as standard. Form a liquid level volume comparison table. Import volume meter, suitable for volume conversion of various regular or irregular tanks.

The meter is equipped with RS232 communication interface as standard. Connect with the host computer. Through the volume download software, data writing for regular and irregular tanks can be realized. 1000 sets of data can be downloaded.

Volume Recorder

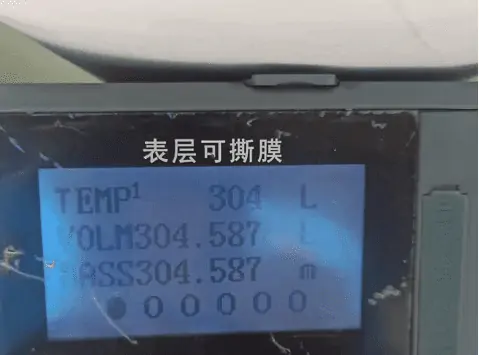

LCD Volume Display Regulator/ Recorder is specifically designed for industrial on-site regular and irregular canned liquid, volume and mass conversion.

It is based on a 32-bit ARM micro-processor and equipped with the secondary meter with high-speed AD and high-capacity storage unit.

The device has empowered by the surface mounting technology, featuring the design of multiple-layered protection and isolation, with a strong anti-interference capability and high reliability.

It has used the embedded operating system with USB data dump function.

The data storage time could reach up to 720 days.

By using U disk and host computer analysis software, one could call and view the historic curve of process variants and relevant historic data from time to time.

It also could match with various liquid sensors, such as ultrasonic liquid level meter. The device has sound anti-theft and anti-damage and other features.

| Measurement Input | ||

| Input Signal | Current: 0~20mA, 0~10mA, 4~20mA, 0~10mA rooting, 4~20mA rooting | |

| Input impedance: ≤ 100Ω | ||

| Maximum input current limit: ≤ 30mA | ||

| Voltage: 0~5V, 1~5V, 0~10V (customized), 0~5V rooting, 1~5V rooting, | ||

| Input impedance: ≥ 500KΩ | ||

| Output | ||

| Output Signal | Analog output: 4~20mA (load resistance ≤ 480Ω), 0~20mA (load resistance ≤ 480Ω), 0~10mA (load resistance ≤ 960Ω), 1~5V (load resistance ≥ 250KΩ), 0~5V (load resistance ≥250KΩ), 0~10 V (load resistance ≥4KΩ) (customized) | |

| Alarm output: relay control output – AC220V/2A, DC24V/2A (resistive load) | ||

| Feed output: DC24V±1, load current ≤ 50mA | ||

| Communication output: RS485/RS232 communication interface, configurable baud rate of 1200~9600bps, standard MODBUS RTU communication protocol, RS-485 communication distance of up to 1km, and RS-232 communication distance of up to 15m. | ||

| General Parameters | ||

| Measuring Accuracy | 0.2%FS±1d | |

| Setting Mode | Touch-panel-based key setting; password locking of parameter settings; permanent preservation of settings upon power failure. | |

| Display | Backlit 3.5-inch 128*64 high-resolution dot-matrix FSTN LCD | |

| Support the display of Chinese characters, figures, curves and bar graphs, as well as screen page turning, historical data search and timescale changes of curves etc. through the panel keys | ||

| Recording Interval | 1, 2, 4, 6, 15, 30, 60, 120, or 240 seconds, nine options available | |

| Storage Length | 3 days (with 1-sec interval) – 720 days (with 240-sec interval) | |

| Printing Control | RS-232C printer interface, supporting SP-A40SH series serial printers | |

| Operating Environment | Ambient temperature: 0~50℃; relative humidity: ≤ 85%RH; avoid strongly corrosive gas | |

| Working Power Supply | AC 100~240V (switching power supply), 50/60HZ; DC 20~29V (switching power supply) | |

| Power | ≤5W | |

| Structure | -Standard snap-in type | |

Frequently

Asked

Questions

Related liquid level monitoring solutions

Sino-Inst offers over 10 level transmitters for Liquid level measurement.

About 50% of these are liquid level meters, 40% is the tank level sensor.

A wide variety of level meters options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.