In the chemical production, the medium often encounters problems such as impurities, crystal particles or agglomeration. It is easy to block the connecting pipeline. At this time, a flange-type differential pressure transmitter is required.

Silicone oil is filled in the closed system composed of the bellows, capillary tube and measuring chamber as the pressure transmission medium. The measured medium does not enter the capillary tube and the transmitter to avoid blockage.

Differential Pressure Level transmitters are divided into single flange type and double flange type according to their structure.

Only a flange between the container and the transmitter is called a single flange differential pressure transmitter.

As for the closed container whose upper end is isolated from the atmosphere, the upper space and atmospheric pressure are mostly different. Two flanges must be used to guide the liquid and gas phase pressure to the differential pressure transmitter. This is the double flange differential pressure transmitter.

Read more What is a diaphragm seal?

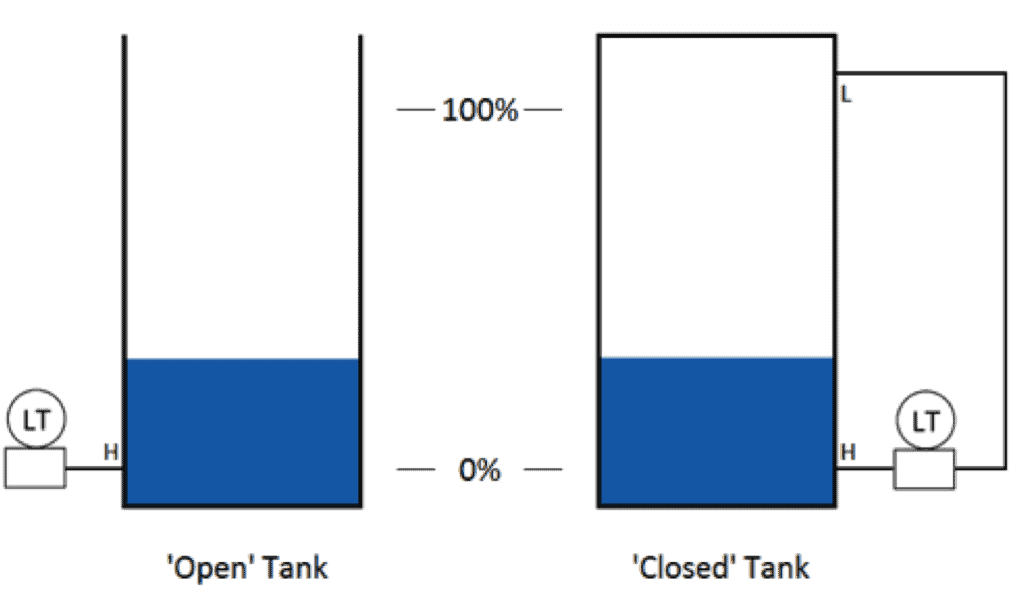

Differential Pressure Level transmitter for open containers

Open tank level measurement means that the tank is open to the atmosphere. Any change in atmospheric pressure will affect the process fluid pressure in the tank. In this liquid level measurement application, the low pressure side of the transmitter can measure the atmospheric pressure. This eliminates the influence of atmospheric pressure on the tank liquid level. The high-pressure side of the transmitter is connected to the tank. Therefore, the actual liquid level in the tank can be measured.

A single flange is used to measure the liquid level of an open tank.

Differential pressure range calculation method: Need to measure the height of the liquid level (unit: m) × acceleration of gravity (9.8) × measured medium density (unit: g/cm3) differential pressure range (unit: KPa).

The selection must know the measurement medium, measuring range, medium temperature, the size and pressure rating of the process connection flange, and the flange standard.

Extended Reading: Differential Pressure (DP) Flow Meters Technology

Differential Pressure Level transmitter for closed containers

For airtight containers, the inside is isolated from the atmosphere. When the process fluid fills or empties the tank, the pressure in the tank may change from positive pressure to vacuum. This change in tank pressure will directly affect the measured liquid level unless it is compensated for. This can be done by connecting the low-side pipe of the differential pressure transmitter to the top of the tank. Therefore, when measuring the liquid level of a closed tank, a differential pressure transmitter must be used.

Double flanges are used to measure the liquid level of a closed tank.

The calculation method of the differential pressure range: the height of the liquid level to be measured (unit: m) × acceleration of gravity (9.8) × (the density of the measured medium-the density of the capillary filling liquid) (unit: g/cm3) = differential pressure range (unit: KPa).

The selection must know the measurement medium, measuring range, medium temperature, pressure, capillary length, the size and pressure rating of the process connection flange and the flange standard

If you need to measure river water level, open channel level, etc. The Ultrasonic Liquid Level Sensor can be used for non-contact continuous level monitoring.

Read more about: 7 Level Senors for Tank Level Measurement

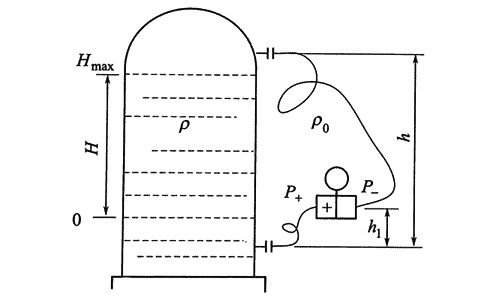

Differential pressure level transmitter working principle

When using Differential pressure (DP) level transmitter to measure the liquid level as shown in the figure below.

The measured liquid density in the figure is ρ.

The working medium density in the capillary of the double flange differential pressure transmitter is ρ0.

The measuring range of the measured liquid level is H.

The center distance of the sampling tube of the measured liquid level is h.

It can be seen from the figure that the maximum measurement range of the liquid level △ P = P + —P- = H × ρ × g-h × ρ0 × g.

It can be seen from the formula that the dual-flange differential pressure transmitter should perform negative migration. The migration amount S is h × ρ0 × g. And the installation position of the double flange differential pressure transmitter has no effect on the migration amount and the measurement result.

The dual-flange differential pressure transmitter requires negative migration.

When the measured liquid level is 0, the pressure difference between the positive and negative measurement chambers of the remote differential pressure transmitter is the largest. The output current of the double flange differential pressure transmitter is 4mA.

As the measured liquid level rises, the pressure difference between the positive and negative measurement chambers of the transmitter gradually decreases.

When the measured liquid level rises to the highest Hmax. The pressure difference between the positive and negative measurement chambers of the transmitter is the smallest. The output current of the double flange differential pressure transmitter is 20mA.

Extended Reading: Procurement Guide for Ultrasonic liquid level sensors

You may like:

- Flow Measurement Units-What Is GPM in Flow Meter?

- What Is a BTU Meter?

- Flow Rate and Pressure Relationship-How to Calculate?

- Pressure Transducers for Air Conditioning & Refrigeration

- Quickly Set Level Monitoring System for Industrial Holding Tanks

- Water Flow Measurement for Pipes and Open Channels

- Analog Pressure Transducers vs Digital Pressure Transducers | How to Choose?

- Vacuum Pressure Transducers | Product List and FAQs

- Industrial Helium Flow Meters

- How to check Level in Underground Tanks? What Tank Level Indicators to Choose?

- What Is Psi in Pressure Sensor?

- What Is a Hydraulic Pressure Transducer? and Product List

- Pressure Transmitter Installation Guide

- What Is Pressure Transducer Output Signal? and Types

- Enhancing Marine Tank Monitoring with Advanced Marine Water Tank Level Sensors

Sino-Inst offers overs 100 DP transmitters for liquid level, pressure, flow, temperature measurement. Differential pressure (dp) level transmitters suit to measeure water and other liquid level.

A wide variety of DP level transmitters are available to you. Such as SMT3151LT Differential pressure level transmitter.

You can also choose from liquid flow meter and pressure transmitters, not specified. We are differential pressure level transmitter suppliers, located in China. The top supplying country is China(Mainland), which supply 100% of DP transmiters respectively.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.