Handheld ultrasonic flow meter realizes the non-contact measurement of liquid flow. Also often referred to as Portable Clamp-On Ultrasonic Flow Meter for Liquids.

Handheld Ultrasonic Flow Meter ( Model:2000H) has been successfully applied to measurement work in various industries. The measuring range is 20-6000mm (0.5-20 inches). A non-contact measurement method is adopted. Flexible operation and easy to carry. Conductive or non-conductive, corrosive or non-corrosive liquids can be measured. Various fluids: water, pure water, sewage, sea water, chemical fluids, river water, fuel Oil etc. can be measured.

Handheld Ultrasonic Flow Meter Reference price: USD 470.00/pc

Sino-Inst offers a variety of Ultrasonic flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Features of Handheld Ultrasonic Flow Meter

- High precision measurement

- Measurement accuracy is better than ±1%, linearity is 0.5%, repeatability is 0.2%

- Small size and light weight

- Volume: 210 × 90 × 30mm, the host weight is only 0.5kg

- Non-contact measurement

- The magnetic flow ultrasonic sensor is adsorbed on the outer wall of the pipe to complete the flow measurement.

- Large measuring range

- Measurement of pipe flow from DN20 to DN2000 with different types of sensors

- Charger

- Built-in large-capacity nickel-metal hydride rechargeable battery to support continuous operation of the flowmeter for more than 12 hoursLarge screen

- LCD display

- It can display cumulative flow, instantaneous flow, flow rate, working status, etc. at the same time.

- Built-in data logger

- Built-in data logger with a space of 24K bytes and can store 2000 lines of measurement data.

Specifications of Handheld Ultrasonic Flow Meter

| Items | Performance and Parameter | |

| Main Unit | Principle | transit-time ultrasonic flowmeter |

| Accuracy |

Accuracy :over 1%-2%; Repeatability: over 0.2% |

|

| Display | 4 line x 16 character LCD with backlight | |

| Dimension |

200*93*33cm: 390g |

|

| Operation |

Support 16 key light touch keyboard and the Simulation keyboard software |

|

| Data interface |

Insulate RS232 serial interface, upgrade the flew meter software by computer, support the MODBUS, etc. |

|

| Signal Output | 1 way OCT output | |

| Special Cable |

Twisted-pair cable ; Select the RS232 communication.; |

|

|

Generally, the standard is 5m*2, optional 10m*2 |

||

| Pipe Condition | Pipe Material |

Steel, Stainless steel, Cast iron, Copper, Cement pipe, PVC, Aluminum, Glass, steel product, liner is allowed. |

| Pipe Diameter | DN 15—6000mm | |

| Straight length pipe |

Transducer installation should be satisfied: upstream10D, downstream 5D, 30D from the pump. |

|

| Measuring Medium | Type of Liquid |

Water ; Ultra-pure liquids; Solvents and other liquids |

| Temperature |

Standard Transducer: -30–90℃; High-temperature transducer: -40–160℃ |

|

| Turbidity | under 10000ppm and less bubble | |

| Flow rate | 0–±10m/s | |

| Flow Direction |

Measuring two (plus-minis) direction of flow rate |

|

| Working Environment | Temperature |

Main Unit: -20–60℃ Flow transducer: -40–160℃; Temperature transducer: according to the customer’s demands. |

| Humidity | Main Unit: 85% RH | |

| Power Supply | AC 110V-240V | |

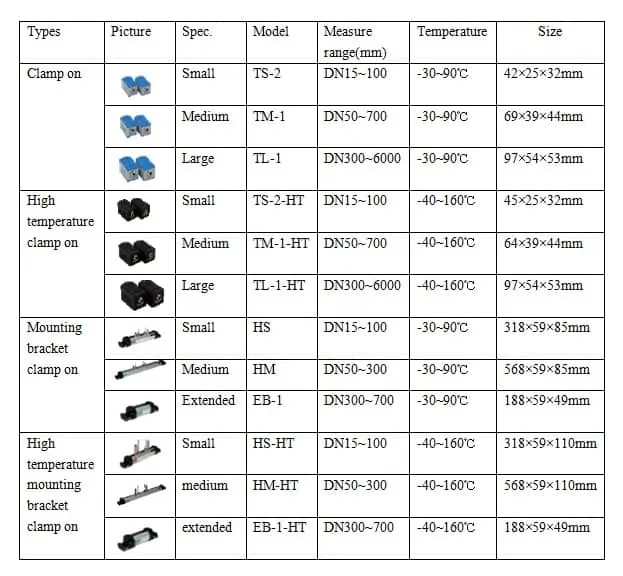

Optional Transducer

Guess You’ll Like: Ultrasonic flow meters types & technical guide

Featured Clamp-on ultrasonic flow meters

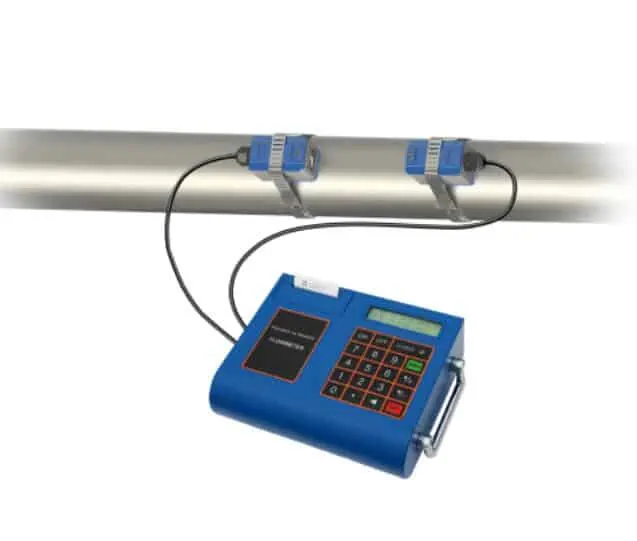

Handheld Ultrasonic Flow Meter is a commonly used clamp-on ultrasonic flow meter.

Clamp-on ultrasonic flow meter mainly refers to the installation form of the ultrasonic sensor. The sensor clamp is fixed outside the pipe.

Clamp-on ultrasonic flow meters can be handheld, wall-mounted, and portable with printing functions depending on the host. You can select different hosts according to your measurement needs.

Typical Applications of Handheld Ultrasonic Flow Meter

The handheld ultrasonic flow meter is mainly used for flow measurement of industrial pipeline fluids, and is widely used in environmental protection, petrochemical, metallurgy, paper-making, food, pharmaceutical and other industries.

The SI-2000H ultrasonic flow meter is ideal for flow testing during test and balance.

It is also useful for temporary flow monitoring, in existing systems to establish baseline demand data.

- Water (hot water, cooling water, potable water, seawater, etc.)

- Petroleum products

- Chemicals, including alcohol, acids, etc

- Beverage, food, and pharmaceutical processors

- Secondary sewage, waste treatment, etc.

- Power plants, Metallurgy, and miming applications

- Pipeline leak detection, inspection, tracking, and collection

Of course, if you are allowed to install a pipe segment flowmeter in your measurement pipeline, you may consider the use of an electromagnetic flowmeter. Electromagnetic flowmeters will provide more accurate measurements.

For example, if you need to measure the wastewater flow of a 2-inch pipe, then you can refer to: Magnetic Flow Meters Guides.

Handheld Ultrasonic Flow Meter Installation

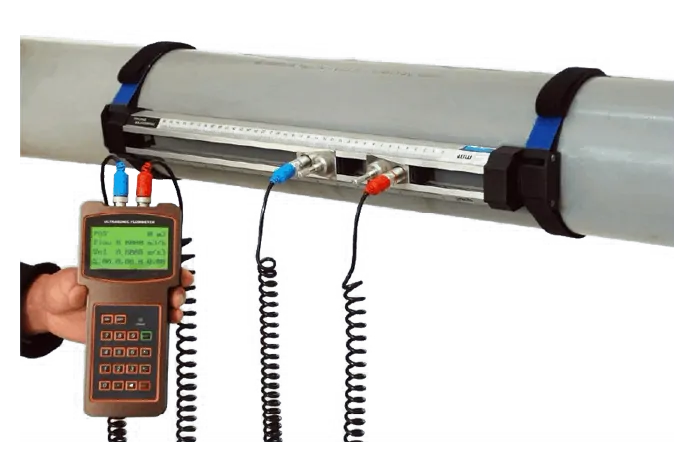

Handheld Clamp on Transducers

- Install the clamp on transducer (with magnet) on the pipe, can finish the flow measurement. No pressure drop, no need cut off pipe.

- Several types transducers for selection, measuring pipe size from DN25-DN6000mm.

- Several types transducers for selection.

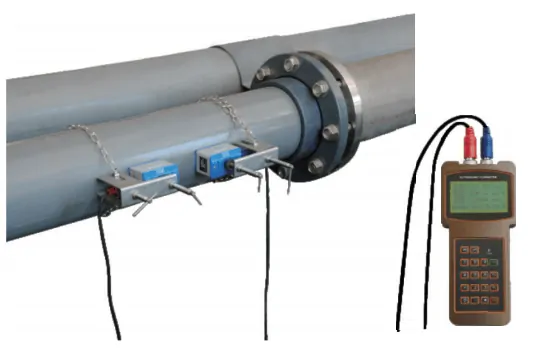

Clamp on Mounting Bracket Transducers

- Bracket transdcuer can simplify the ultrasonic flow meter installation process. Shorten installation time and improve installation accuracy.

- Install the clamp on bracket transducer (with magnet) on the pipe. Can finish the flow measurement. No pressure drop, no need cut off pipe.

- Several types bracket transducers for selection, measuring pipe sizing from DN25-DN700mm.

- Several types bracket transducers for selection, measuring temperature range -30℃ to 160℃.

Check more Choosing The Right 1 Inch Flow Meter.

Portable ultrasonic flow meter for water

Ultrasonic flowmeter is especially suitable for measuring large-diameter liquid pipelines because of its measuring principle. It has a large number of applications in urban water supply and sewage treatment industries. And the measurement results are very good.

Water is often used as circulating water in industrial production. That is, the water that can be recycled as the carrier of heat in the production process of the enterprise. The beginning is a circulating pool with a cooling system, and the end is the heat exchange equipment of the production workshop.

There are many types and quantities of heat exchange equipment in biochemical companies, so the circulating water pipelines are complicated. If a flow meter is installed on each circulating water pipeline, it will be a considerable expense.

Therefore, most production companies do not install flow meters for circulating water pipes in the initial stage of design to reduce investment costs. However, in order to grasp the operating efficiency of all heat exchange equipment in the production process, it is necessary to detect the flow rate of the circulation in the pipeline. .

An ultrasonic flowmeter can be used as a standard meter to transmit the value. It not only protects water resources rationally and scientifically, but also quantifies the paid use of water resources to a great extent. At the same time, it also protects the interests of both parties who use the water and reduces the cost of enterprise inspection. This makes periodic verification of large-caliber water flow meters a reality.

Handheld ultrasonic flow meter manual:

More Featured Liquid Flow Meters

Frequently

Asked

Questions

Related Blogs

Sino-Inst, Manufacuturer for Handheld Ultrasonic Flow Meters. It can measure a single sound-conducting liquid medium of DN 15—6000mm. It can measure even liquids such as water, sea water, oil, and slurry.

Sino-Inst’s Handheld Ultrasonic Flow Meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

Handheld ultrasonic flow meter|Clamp on-Portable|Sino-Inst

Handheld ultrasonic flow meter realizes the non-contact measurement of liquid flow. Also often referred to as Portable Clamp-On Ultrasonic Flow Meter for Liquids.

Product SKU: Handheld Ultrasonic Flow Meter

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 420

Price Valid Until: 2029-07-10

Product In-Stock: InStock

5