What is a flow nozzle?

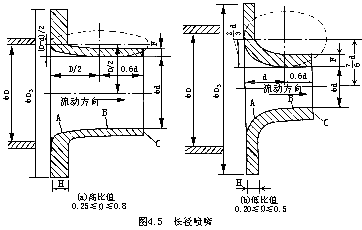

Flow nozzle is also called a standard nozzle flow meter, standard nozzle, ISA1932 nozzle. It is a differential pressure flow meter suitable for high temperature and high-pressure fluid measurement.

Flow nozzle, like standard orifice plate, venturi tube flowmeter, and venturi nozzle, belongs to the standard throttling device specified by national standards. The pressure loss of the nozzle flowmeter is small, so it saves energy, is more sturdy and durable, suitable for high temperature and high-pressure fluids, and is widely used in steam flow measurement in electric power, chemical, and other industries.

Features of Flow Nozzle

Compared with the orifice Flowmeter, the pressure loss of the nozzle Flowmeter is small, so it saves energy, is more durable, suitable for high temperature and high-pressure fluid, and is widely used in steam flow measurement in electric power, chemical industry, and so on.

Nozzle flowmeter produced by our company includes a standard nozzle (ISA1932 nozzle), long neck nozzle two. The design and manufacture are in accordance with international standard ISO5167 or national standard GB/T2624.

- Nozzle Flowmeter throttle structure is easy to copy, simple, firm, stable and reliable performance, long service life.

- Nozzle is less pressure loss than orifice plate, the length of straight pipe section is also short.

- Nozzle calculation adopts international standard and processing, check according to JJG640-94, no real flow check.

- Accuracy is high, repeatability is good, outflow coefficient is stable.

- Circular arc structure design can measure various liquids, gases, steam and various dirty media.

- Can withstand high temperature and high pressure, impact resistance.

Read more Chemical flow meters|Chemical resistance for Liquids and Gas

Working principle of nozzle flowmeter

The nozzle measurement is based on the throttling principle of fluid mechanics.

When the fluid-filled with the pipe flows through the nozzle in the pipe, the flow beam will form a local contraction at the nozzle, thus accelerating the flow rate and reducing the static pressure.

Then in the nozzle before and after the pressure drop or called pressure difference. The greater the flow rate of the medium, the greater the pressure difference before and after the nozzle.

According to the relationship between the square root of the pressure difference and the flow rate, the differential pressure meter is used to measure the pressure difference to determine the fluid flow rate.

Read more about Steam pressure transmitter-Pressure measure on steam pipeline

Nozzle Flow Meter Equation

Flow Nozzles Types

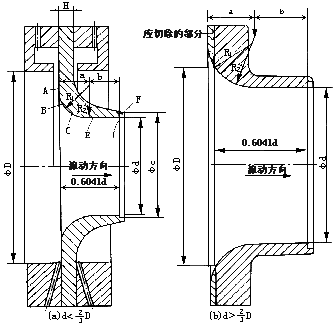

Standard nozzles (ISA1932 nozzles)

- Suitable medium; especially suitable for high temperature and high pressure steam and water, and also for various gases and liquids

- Nominal Caliber: DN50—500mm (DN >500 can also be designed, produced)

- Work stress :≦42 MPa

- Operating temperature :-50℃-650℃

- Pressure-taking mode: angular joint (single ring chamber, flange ring chamber or direct drilling) pressure-taking

- Nozzle installation: Flange (direct bore and presser), fastener holder

- Flange, ring chamber, fastener holder

- Grip (and press) welded

- Implementation criteria: IS05167;GB/T2624

- Accuracy: compliance :±1.0 per cent

- Material: Flange or gripper: Carbon steel, alloy steel, stainless steel, etc. optional according to medium temperature

- Nozzle: Stainless Steel 304,316, etc

Long radius nozzle

- Suitable medium; especially suitable for high temperature and high pressure steam and water, and also for various gases and liquids

- Nominal calibre: DN50—630mm

- Work stress :≦42 MPa

- Operating temperature :-50℃-650

- Pressure-taking mode: diameter distance (D-D/2) pressure-taking

- Installation of nozzle parts: with tape and welding of upper and lower pipe sections and then setting pressure holes according to diameter distance (D-D/2)•

- Implementation criteria: IS05167;GB/T2624

- Accuracy: compliance :±2.0 per cent

- Material: Carbon steel, alloy steel, stainless steel, etc. can be selected according to medium temperature.

- Nozzle: Stainless Steel 304,316, etc

Extended reading: Vortex Steam Flow Meter

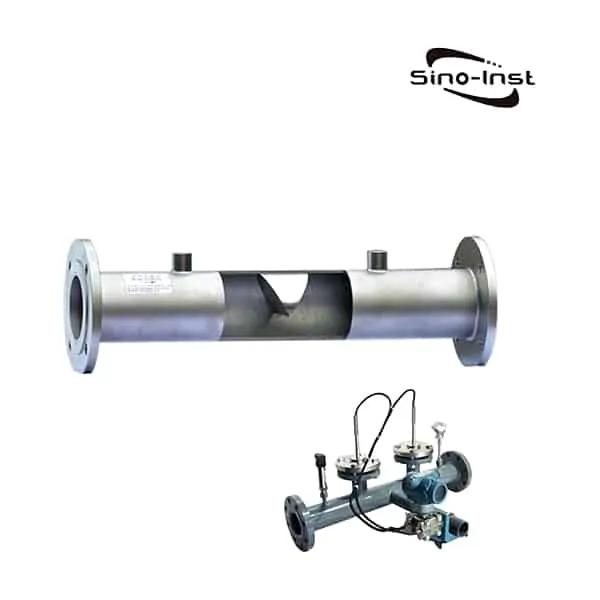

Flow Nozzle Construction

Nozzle Flow Meter Advantages and Disadvantages

Advantage:

- The standard nozzle has a long history and a large amount of various test data.

- The nozzle flowmeter has a simple and firm structure, no moving parts, and is stable and reliable for long-term use.

- Rich experience in design, manufacture and application, high standardization, no need for real-flow calibration.

- The standard nozzle has reliable experimental data and perfect international and national standards. The measurement data is true and credible and can be used as a meter for trade settlement.

Disadvantages:

- The production is more complicated and the unit price is higher.

- The flow rate of the nozzle flowmeter. When the pressure difference between the front and back of the nozzle is greater than a certain value, the flow rate through the nozzle is a fixed value, and the measurement accuracy level is high;

- Generally used as standard devices.

Extended reading: Integral DP Flow Meter|Gas, liquid, steam|Compact structure

Extended Reading: Advantages and disadvantages of differential pressure flow meter

Flow Nozzle for Steam Flow Measurement

Steam flow meters are widely used in petroleum, chemical, metallurgy, pharmaceutical, electric power, papermaking and other industries to measure steam flow.

The nozzle steam flowmeter has the characteristics of high temperature and high pressure resistance, impact resistance, long service life, large measurement range, high measurement accuracy, and small pressure loss. It can be used for trade settlement. The standard nozzle is designed and manufactured according to the national standard GB/T2624-2006, and it is verified according to the national standard JJG640-94. No need for real-flow calibration.

The inlet of the JT-BPZ standard nozzle steam flow meter is divided into ISA standard nozzle and long diameter nozzle according to the arc-shaped contour structure.

Common nozzle flowmeter types in the main steam pipeline

In the main steam pipeline of power station boilers, the flow meters we commonly see are mainly ISA1932 nozzle flowmeters and long-diameter nozzle flowmeters.

The ISA1932 nozzle flowmeter is mainly composed of a standard nozzle, two pressure pipes, and two ring-type short sections butt welded together.

The long-diameter nozzle flowmeter is mainly composed of a long-diameter nozzle, a positioning pin, a supporting ring, two pressure-taking pipes, and a measuring pipe.

Of course, there are many types of flow meters available for steam flow meters. How to choose and use it should be analyzed and selected according to the specific situation. You can refer to: How to choose a flowmeter for steam measurement.

Extended reading: V-Cone Flow Meter Applications

Flow nozzle vs Venturi

Venturi flow meter is a flow measurement method based on the principle of differential pressure. Commonly used to measure the flow of fluids such as air, natural gas, coal gas, and water. In the standard throttling device, the upstream and downstream straight pipe sections required by it are short. The lasting pressure loss is small, the performance is stable, and the maintenance is convenient.

Extended reading: What Is A Venturi Flow Meter?

FAQ

How does a flow nozzle work?

When a flow nozzle is placed in a pipe carrying whose rate of flow is to be measured, the flow nozzle causes a pressure drop which varies with the flow rate. This pressure drop is measured using a differential pressure sensor and when calibrated this pressure becomes a measure of flow rate.

Extended reading: High-Temperature Oval Gear Heating oil Flow Meter

You may like:

Sino-Inst, Manufacuturer for differential pressure flow meters. Including Flow Nozzle, Orifice plate, Venturi, Annubar, etc. Suitable for liquid, gas and steam flow measurement.

Sino-Inst’s differential pressure flow meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

Flow Nozzle |DP flow meter| Long radius- Corner tapping

Flow nozzle flow meter is a differential pressure flow meter suitable for high temperature and high pressure fluid measurement.

Product SKU: Flow Nozzle

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 990

Price Valid Until: 2059-09-30

Product In-Stock: InStock

5