Horn Antenna Radar Tank Level Sensor is a common non-contact tank level meter. Suitable for high temperature sealed storage tank. Support customized high temperature 500-1000℃.

Horn Antenna Radar Tank Level Sensor has good focusing characteristics and can be applied to most tanks. If the corresponding cooling measures are adopted, the temperature of the measured medium can reach 500-1000℃. The maximum measuring distance is 35 meters. It can be used for level measurement of storage tanks, intermediate buffer tanks or process vessels. But it is not suitable for measurement of corrosive media. Output 4~20mA superimposed HART signal.

Sino-Inst offers a variety of Horn Antenna Radar Tank Level Sensors for industrial level measurement. If you have any questions, please contact our sales engineers.

Features of SIRD-905 Horn Antenna Radar Tank Level Sensor

- Non-contact continuous liquid level measurement with larger range

- High-precision and precise transit time measurement brought by high-frequency pulse waves

- Sealed pressurized container will not affect performance

- Longer range than ultrasound

- If the corresponding cooling measures are adopted, the temperature of the measured medium can reach 1000°C.

Specifications of SIRD-905 Horn Antenna Radar Tank Level Sensor

| Application: | Solid particles, powder |

| Measuring Range: | Liquid 35 meters / solid block 20 meters / solid powder 15 meters |

| Process Connection: | Thread, flange |

| Process Temperature: | -40~130℃(standard type) / -40~250℃(high temperature type)/customized high temperature |

| Process Pressure: | -0.1~4.0 MPa (flat flange) -0.1~0.3 MPa (universal flange) |

| Accuracy: | ±15mm |

| Protection Grade: | IP67 |

| Frequency Range: | 26GHz |

| Supply: | Two-wire system (DC24V) / Four-wire system (DC24V/AC220V) |

| Signal Output: | Exia ⅡC T6 Ga / Exd IIC T6 Gb |

| Outer Covering: | Aluminum Single Chamber / Aluminum Dual Chamber / Plastic / Stainless Steel Single Chamber |

| Explosion-proof Grade: | 4…20mA/HART (two-wire/four-wire) / RS485 Mod bus |

| Antenna Material | Stainless steel 316L horn/PTFE vibrator, cone antenna |

Radar Tank Level Sensor Applications

- Power plants: coal piles, raw coal silos, fuel silos, reservoirs, waste gas purification tanks, silo pumps, ash storage, fuel tanks, etc.;

- Oilfield: crude oil or product oil storage tanks, three-phase separators, settling tanks, sewage tanks and oil-water interfaces, drilling mud tanks, etc.;

- Chemical industry: crude oil distillation tower, raw material and intermediate silo, reaction tank, ammonia tank, solid silo, separator, etc.;

- Metallurgy: ore silo, ore crusher, raw material silo, auxiliary silo, blast furnace, alumina powder silo, electrolytic cell buffer tank, etc.;

- Papermaking: raw material warehouse, storage tower, drying drum, chemical material storage warehouse, etc.;

- Cement: storage warehouse for stone, raw meal, cement, coal powder, slag, etc.;

- Water treatment: water storage, sewage, sedimentation, deep well, drinking water and other pools;

- Others: quarry, food, pharmaceutical, environmental protection, shipbuilding and other industries;

Extended reading: Radar level sensor for solids – Dust solid level measurement

Radar Tank Level Sensor Installation Notes

(1) The horn of the horn-type intelligent radar level gauge must exceed the inner surface of the mounting hole by a certain interval (at least greater than 10mm).

(2) The axis of the antenna of the intelligent radar level gauge should be perpendicular to the reflective surface of the liquid level.

In addition, when performing routine maintenance on the intelligent radar level gauge, users can remotely observe the reflected wave curve with a PC (equipped with MAT software). For interference waves that may be newly generated later, the level gauge can be used to identify false waves. Remove the influence of these interference reflection waves to ensure correct measurement.

(3) Objects such as the stirring valve in the tank, the adhesion of the tank wall and the path. If it is within the signal range of the intelligent radar level gauge, it will produce interfering reflected waves and affect the level measurement. When installing, choose a suitable installation location to avoid interference from these factors.

Extended reading: Radar Level Meter for Corrosive Liquids

Radar Tank Level Sensor Installation Guide:

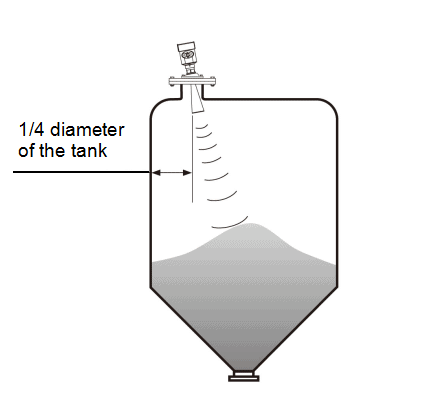

Be installed in the diameter of the 1/4 or 1/6.

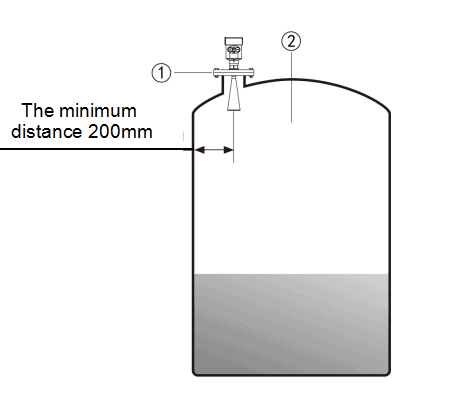

Note: The minimum distance from the tank wall should be 200mm.

Note: ① datum

②The container center or axis of symmetry

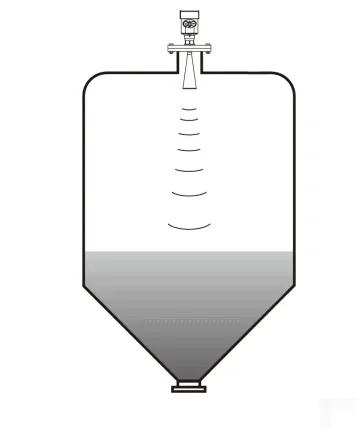

The top conical tank level, can be installed at the top of the tank is intermediate, can guarantee the measurement to the conical bottom. Extended Reading: Case: High Temperature Radar Level Transmitter for Melted Salt-Solar Photovoltaic Power Station

A feed antenna to the vertical alignment surface.

If the surface is rough, stack angle must be used to adjust the angle of universal flange of the antenna to the alignment surface.

(Due to the solid surface tilt will cause the echo attenuation, even Loss of signal.)

Extended reading: guided wave radar level sensor advantages and disadvantages

Radar Level Sensor Working Principle

Radar level transmitter antenna microwave pulse is narrow, the downward transmission antenna.

Microwave exposure to the medium surface is reflected back again by the antenna system receives, sends the signal to the electronic circuit automatically converted into level signals.

Because the microwave propagation speed, electromagnetic wave to reach the target and the reflected back to the receiver this time is almost instantaneous.

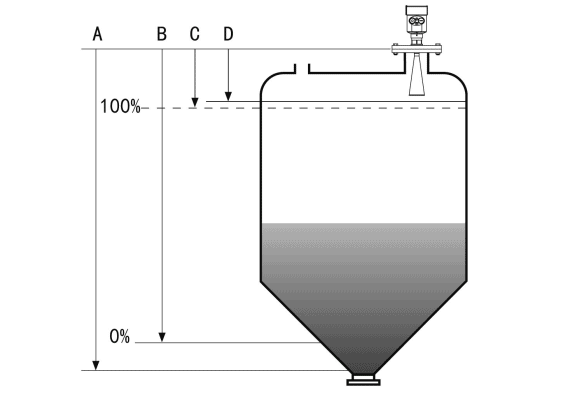

A Range set

B Low adjustment

C High

D Blind area

Datum measurement: Screw thread bottom or the sealing surface of the flange.

Note: Make sure the radar level meter the highest level cannot enter the measuring blind area (Figure D shown below).

Extended reading: GWR Solid Level Sensor-Cement silo-Ash powder measure

Featured Tank Level Sensors

FAQ

What is the difference between radar and ultrasonic level transmitter?

In actual application, there are two methods for radar level sensors, namely, frequency modulated continuous wave type and pulse wave type. The liquid level sensor using FM continuous wave technology has high power consumption, must adopt a four-wire system, and the electronic circuit is complicated. The liquid level sensor using radar pulse wave technology has low power consumption and can be powered by two-wire 24VDC, which is easy to achieve intrinsic safety and has a wider application range.

Ultrasonic sensors use sound waves, and radar uses electromagnetic waves. This is the biggest difference.

Moreover, the penetrating ability and directivity of ultrasonic waves are much stronger than electromagnetic waves, which is why ultrasonic detection is more popular now.

The difference between the main applications:

1. Ultrasonic accuracy is not as good as radar.

2. The relative price of radar is relatively high.

3. When using radar, consider the dielectric constant of the medium.

4. Ultrasound cannot be applied to working conditions such as vacuum, high steam content or foam on the liquid surface.

5. The radar measurement range is much larger than that of ultrasonic.

6. The radar has a horn type, a rod type, and a cable type. Compared with ultrasonic, it can be applied to more complicated conditions.

Read more: Guide: Non-contact Ultrasonic Level Sensing transmitters

What are the different types of level sensors?

Types of Level Transmitters:

Level measurement transmitters are of seven types. Each type of transmitter works in a different way, and makes it useful for different types of processes.

Capacitance Level Transmitters

Hydrostatic Level Transmitters

Magnetic Level Transmitters

Radar Fill Level Transmitters

MUltrasonic Level Transmitter

Guided Microwave Level Transmitters

Hydrostatic level transmitters

Extended reading: GWR Solid Level Sensor-for Cement silo-Ash powder measure

Sino-Inst offers over 10 Horn Antenna Radar Tank Level Sensors for level measurement. About 50% of these are Radar level meters, 40% is the tank level sensor.

A wide variety of Radar level Sensor for level measurement options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of radar level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.