Ultrasonic Level Transducer, also called Ultrasonic level sensor, or ultrasonic level transmitter.

Ultrasonic level meter (measuring material level, liquid level) is a non-contact, highly reliable, cost-effective, and easy-to-install and maintain level measuring instrument. It can meet most of the level measurement requirements without contacting the medium.

Features of Ultrasonic Level Transducer

- The large measuring range can reach 40m, and the solid material level measurement can reach 25m.

- The small resolution is 1mm.

- Large LCD/LED display.

- Intelligent signal processing technology.

- All plastic anticorrosive shell: protection grade IP67.

- Transducer structure: There is no requirement for flange connection length when the small range level meter is flanged.

- Simple button setting parameters: no need to wait for the container to empty or fill up, no need for an additional remote control.

- Flexible installation methods: thread (flange), fixed hole (bracket).

- The probe can be extended: it is suitable for outdoor installation in a closed container in cold areas to prevent frost.

- Equipped with high and low double relays: the four-wire system provides this function.

- AC and DC power supply forms are optional: four-wire system and split machine mainframe provide this function.

Ultrasonic level gauge and other level gauge technologies

- Compared with laser ranging technology, it has the advantages of simplicity and economy;

- Ultrasound technology generally does not require moving parts, so installation and maintenance are relatively convenient;

- Ultrasonic level meter can not only fix point and continuous position measurement, but also can conveniently provide signals required for remote measurement or remote control;

- Compared with the radioactive location technology, the ultrasonic level meter does not require protection.

Technical characteristics

- Transducer with strong emission power. The surface can be self-cleaning. The use of updated transducer structure and manufacturing technology. The working performance of the transducer is significantly improved.

- Microprocessor program control and intelligent signal processing technology can realize a variety of typical working condition software processing modes. The level meter can adapt to complex working conditions such as solids, liquids, and dust.

- Infrared remote control programming adjustment, simple and reliable operation, and with LCD on-site display.

- Non-contact continuous measurement, reducing maintenance;

- It can be used to measure level, space and distance, and can also perform automatic level-volume conversion for standard or special switch tanks;

- The LCD with backlight can display according to standard engineering units.

Specifications of Ultrasonic Level Transducer

| Features | Integral type | Split type |

| Range | 5 meters, 10 meters, 15 meters, 20 meters, 30 meters, 40 meters, 50 meters, 60 meters | 5 meters, 10 meters, 15 meters, 20 meters, 30 meters, 40 meters, 50 meters, 60 meters, 70 meters, |

| measurement accuracy | 0.5%-1.0% | 0.5%-1.0% |

| Resolution | 3mm or 0.1% (whichever is greater) | 3mm or 0.1% (whichever is greater) |

| display | Chinese LCD | Chinese LCD |

| Analog output | 4-wire 4~20mA/510Q load; 2-wire 4~20mA/250Q load | 4~20mA/510Q load |

| Relay output | Optional 2 groups of AC250V/8A or DC; 30V/5A state programmable | (Optional) Single-channel is 2 groups, dual-channel is 4 groups AC250V/8A or DC30V/5A state programmable |

| powered by | Standard 24VDC; optional 220VAC+15%50Hz | Standard 220VAC+15%50Hz; optional 24VDC120mA; customized 12VDC or battery power supply |

| Ambient temperature | Display instrument -20~+60℃, probe -20~+80℃ | Display instrument -20~+60℃, probe -20~+80℃ |

| Communication | Optional 485,232 communication (manufacturer agreement) | Optional 485,232 communication (manufacturer agreement) |

| Protection level | Display instrument IP65, probe IP68 | Display instrument IP65, probe IP68 |

| Probe cable | no | Up to 100 meters, standard 10 meters |

| Probe installation | According to the range and probe selection | According to the range and probe selection |

Ultrasonic level meter application

Liquid level and material level measurement is a problem frequently encountered in the industry. Ultrasonic positioning technology has many advantages. It can not only fixed-point and continuous positioning. And it can conveniently provide signals required for telemetry or remote control.

Compared with radioactive location technology, ultrasound technology does not require protection.

Compared with laser-ranging technology, it has the advantages of simplicity and economy.

At the same time, ultrasound technology generally does not require moving parts. Therefore, it is relatively convenient to install and maintain.

Ultrasonic level gauges can be widely used in petroleum, mining, power plants, chemical plants, water treatment plants, sewage treatment stations, agricultural water, environmental monitoring, food (brine industry, beverage industry, additives, edible oil, dairy products), flood control Flood prevention, hydrological monitoring, open channels, spatial positioning, and many other industries.

Read more about: Application 1: Liquid Level Monitoring In The Food And Beverage Processing

Learn More: Sanitary ( hygienic ) Pressure Transmitter

What is ultrasonic level measurement?

Ultrasonic waves detect an object in the same way as Radar does it.

Ultrasonic uses sound waves, and Radar uses radio waves.

When the ultrasonic pulse signal is targeted towards an object, it is reflected by the object, and the echo returns to the sender.

The time traveled by the ultrasonic pulse is calculated, and the distance of the object is found.

Bats use a well-known method to measure the distance while traveling.

The ultrasonic level measurement principle is also used to find out fish positions in the ocean, locate submarines below water level, also the position of a scuba diver in the sea.

Level = Speed of sound in air x Time delay / 2

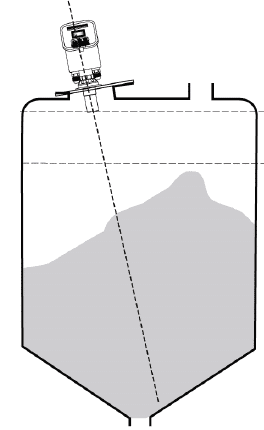

Ultrasonic level transducer working principle

During level measurement. The ultrasonic signal is sent out by the ultrasonic probe. Fold back after being reflected on the surface of a liquid or solid material. It is received by the same probe and measures the entire running time of the ultrasonic wave, so as to realize the level measurement. The relationship between sound wave transmission distance and sound speed and sound transmission time can be expressed by the formula:

The calculation formula of the ultrasonic level meter The calculation formula L of the ultrasonic level meter: the distance between the ultrasonic probe and the measured material surface. Unit: m;

v: Sound velocity value after temperature compensation. Unit: m/s;

t: The running time of the sound wave in the measuring range. Unit: s

Extended reading: The Secret of Ultrasonic Level Measurement

Introduction to the main indicators of Ultrasonic Level Transducer

- Range.

It represents the large range that the ultrasonic level meter can measure and reflects the sensitivity of the transducer.

The larger the range, the higher the sensitivity.

The ultrasonic level meter can be equipped with transducers of different ranges such as 4, 6, 8, 10, 20, 30m.

When the ultrasonic attenuation is fast and the interface reflection is poor. In order to avoid the ultrasonic signal received by the ultrasonic probe is too weak. If it cannot be distinguished from the noise signal, it is necessary to increase the transmitting power of the transducer. - Blind area.

It is also called the dead zone, which is a distance that cannot be measured by the ultrasonic level meter.

When the ultrasonic level meter transmits ultrasonic pulses, it cannot detect the reflected echo at the same time.

Because the transmitted ultrasonic pulse has a certain time width. At the same time, the sensor still has after-vibration after transmitting the ultrasonic. During this period, the reflected echo cannot be detected. Therefore, a small distance from the probe surface downward cannot be detected normally, and this distance is called a blind zone.

For products with the same measuring range, the smaller the blind zone, the better the design of the transducer. - Temperature.

The normal range is -10~60 degrees Celsius.

Although the limit working temperature of piezoelectric ceramics is generally 150 degrees Celsius. However, most of the materials in the manufacturing process of the ultrasonic level gauge cannot work for a long time at a temperature above 100 degrees Celsius. - Precision.

It is mainly affected by temperature changes to ensure measurement accuracy. Most ultrasonic level meters are equipped with temperature compensation.

In addition, changes in the gas composition will also affect the accuracy of the ultrasonic level gauge. For example, some volatile liquids. After volatilization, the air composition changes and the sound velocity of the gas changes, causing measurement errors. Most manufacturers can control the accuracy within 0.5% under normal temperature and pressure and without interference from the external environment. - Two-wire system and three-wire system.

The power supply (DC24v) and signal output (DC4-20mA) of the two-wire ultrasonic level meter share the same circuit. That is, only two wires are used. The disadvantage is that the transmit power is relatively weak.

The three-wire ultrasonic level meter is actually a four-wire system. Its power supply (DC24v) and signal output (DC4-20mA) loops are separated. Two wires are used for each. When their negative ends are connected to the common ground, three wires are usually used . Its advantage is that the transmit power is larger.

Extended reading: Applicaitons Of Magnetostrictive Level Transmitters

Ultrasonic Level Transducer measurement influencing factors

Various factors will affect its stable and reliable measurement when it is actually used in the field. Below we will combine the actual situation to describe the influence of various interferences on the selection, use and installation of ultrasonic level meters.

(1) The influence of medium and ambient temperature

When the ultrasonic wave is reflected from the surface of the material, its reflection frequency will be affected by the temperature of the material and change. In order to compensate for this change, a temperature sensor is installed in the ultrasonic probe. When the probe sends the reflected signal to the processor at the same time. The temperature signal is also sent to the microprocessor, and the processor will automatically compensate for the influence of temperature on the level measurement.

In addition, in order to ensure the reliable operation of the probe, it is required that the ambient temperature does not exceed 60°C.

(2) The influence of the agitator on the measurement of the level meter

If the material container is equipped with a stirrer, it will also reflect the ultrasonic signal, causing false reflection echo, which is transmitted to the microprocessor.

The microprocessor will process the true and false mask echoes based on statistical principles, so it is required that the echo reflected by the ultrasonic wave from the surface of the material should be at least 3 times the echo reflected from the stirrer arm.

Appropriately reduce the speed of the stirrer, or move the probe away from the stirring center. Both can effectively eliminate the influence of the false surface reflection produced by the agitator on the level measurement.

(3) Ultrasonic level meter measures the limit value of the material level

1) High material level

When an ultrasonic pulse is transmitted to the surface of the material, if it receives a reflected wave from the surface of the material, it will not be able to measure, and this distance is a blind zone. The material level shall not be higher than the blind zone.

2) Low material level

The di level is the distance from the sensor that the ultrasonic wave can reach. And the reflected echo can be received by the sensor. Due to the attenuation of ultrasonic waves in the propagation process and the absorption of sound waves on the surface of the material, this propagation distance is strongly dependent on the nature of the material.

In short, as long as the instrument is selected and installed properly, the application effect of the ultrasonic level gauge is quite satisfactory.

Extended reading: How to Choose the Right Diesel Fuel Level Sensor?

More Featured Products

Sino-Instrument offers 20 ultrasonic level transducers products.

About 13% of these are ultrasonic level transmitters, 4% are an ultrasonic level indicator.

A wide variety of ultrasonic level transducer options are available to you, such as free samples, paid samples.

Sino-Instrument is an ultrasonic level transmitter supplier, located in China.

Ultrasonic level transducer products are most popular in North America, Mid East, and Eastern Europe.

The United States, and India, which export 99%, 1%, and 1% of ultrasonic level transmitters respectively.

You can ensure product safety by selecting from a certified supplier, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.