0-10V pressure transducers with their 3 or 4 wire configurations, work tirelessly to monitor and control water pressure gauges, air pressure, vacuum pressure, and more.

Whether it’s a 10 bar absolute pressure or delicate differential pressure, these transducers can handle it all. As they convert psi into a voltage output signal, they bridge the gap between the tangible world and the realm of digital communication.

What is 0-10V signal output?

A 0-10V signal output is a method of electrical communication that utilizes voltage levels ranging from 0 volts to 10 volts to represent specific values within a given measurement scale. This standardized analog communication allows devices to convey information through varying voltage signals, facilitating seamless data exchange and interpretation in various applications.

What are 0-10V Pressure Transducers?

0-10V pressure transducers are devices that measure pressure changes in various environments, such as water, air, or vacuum. These transducers convert the pressure variations they detect into a 0-10V analog signal output, which corresponds to the measured pressure values. This standardized output allows for easy integration and communication with other devices, making 0-10V pressure transducers valuable tools in a wide range of applications.

Read more about:

How to convert a 4-20mA to 0-10V /1-5V signal?

Pressure Transducer Wiring: 2 Wire-3 Wire-4 Wire

Featured 0-10V Pressure Transducers Parameters

| Range: | 0 ~ 1KPa ~ 10KPa ~ 400KPa, -0.1 ~ 0 ~ 1 ~ 60 (MPa), 0 ~ 10KPa ~ 100MPa, High pressure 700MPa can be customized; |

| Comprehensive accuracy: | 0.25% FS, 0.5% FS |

| Output signal: | 4-20mA (2-wire system), 0-5 / 1-5 / 0-10V (3-wire system) |

| Power supply voltage: | 24DCV (9 ~ 36DCV) |

| Medium temperature: | -30 ℃ ~ 160-350 ℃, customized up to 800 ℃. |

| Ambient temperature: | Normal temperature (-20 ~ 85 ℃) |

| Load resistance: | Current output type: maximum 800Ω; voltage output type: greater than 50KΩ |

| Insulation resistance: | Greater than 2000MΩ (100VDC) |

| Long-term stability: | 0.1% FS / year |

| Vibration effect: | In the mechanical vibration frequency 20Hz ~ 1000Hz, the output change is less than 0.1% FS |

| Electrical interface: | Hessman connector (customizable) |

| Thread connection: | M20 × 1.5, etc. Other threads can be designed according to customer requirements |

| Dimensions: | M20 × Φ26.5 × 156 |

| Shell protection: | Plug type (IP65); cable type (IP67) |

| Safety explosion-proof: | Ex iaⅡ CT5 |

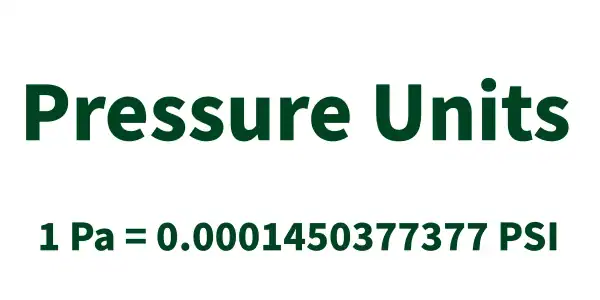

Read more about: Common Units Of Pressure

Checklist for 0-10v Pressure Transducers?

Use this comprehensive checklist to define your 0-10V output signal pressure transducer requirements, ensuring that you select the perfect device for your needs:

By carefully considering each aspect of this checklist, you’ll be well-equipped to select the ideal 0-10V pressure transducer for your specific application.

Frequently

Asked

Questions

More Pressure Measurement Solutions

Exploring Common Units of Pressure: A Comprehensive Guide For Pressure Units

Checklist: Pressure Transmitter 4-20mA Common Faults and Error

Difference in Details: Pressure Transmitter vs Pressure Gauge

Ship Ballast Tank Pressure-Liquid Level Measurement

Water Pressure Sensors for Measurement of Water Pressure

Flow Pressure Transducers for Fluid Pipelines

In conclusion, 0-10V pressure transducers have become an indispensable part of modern pressure measurement technology. These remarkable devices, with their ability to convert pressure changes into corresponding voltage signals, have revolutionized the way we monitor and control various applications. Understanding the intricacies of these transducers and their 3 or 4 wire configurations will empower you to make well-informed decisions for your specific needs.

At Sino-Inst, we take immense pride in our role as a professional manufacturer of pressure sensors and pressure transmitters. Our vast experience and commitment to quality have made us a trusted partner in the industry, ensuring that our customers receive reliable and high-performing products. Let us be your guide on this exciting journey towards better pressure measurement and control.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.