Pressure transmitters convert pressure signal into 4 ~ 20mA DC, 0-5V, 0-10V signal output.

The signal system of 4-20mA and 1-5V output by the pressure transmitter is stipulated by international standards.In the signal circuit, the pressure transmitter is equivalent to a variable resistor. It is connected in series with the power supply, ammeter (indicator), and load resistance (including wire resistance). The function of the pressure transmitter is to change the current in the circuit in the range of 4-20mA by changing its own resistance according to requirements.The pressure acts on the sensor, and the sensitive element deforms. The deformation will cause the resistance or capacitance value to change. And then it will be converted into an analog 4-20mA output by the conversion circuit.

Sino-Inst offers a variety of 4-20mA pressure senors for industrial pressure measurement. If you have any questions, please contact our sales engineers.

The SI-300 4-20mA/Voltage Pressure Transducer, also called pressure transmitter 4-20mA. It is a pressure sensor with 4-20ma/Voltage output.

4-20mA Pressure Transducer can be OEM as differential pressure, explosion-proof, or sanitary, just as you need.Ideal for OEMs, process applications, water processing, and industrial pressure applications.

Features of SI-300 Pressure Transducer 4-20mA/Voltage

- Sensor Type : Industrial Pressure Transducers

- Pressure Range : 0 – 25 to 14000 psi

- Output/Span : .5 – 4.5 V, .5 – 4.5 V, 1 – 5 V, 1 – 6 V, 10 mV/V, 4 – 20 mA

- Type : Compound, Gage, Sealed

- Accuracy : ±0.5% FSO

All of our pressure transmitters can work with the new AMS TREX

Specifications of SI-300 Pressure Transducer 4-20mA/Voltage

| Range range | -100kPa…0~10kPa…100MPa (14000psi) |

| Pressure type | Gauge pressure, absolute pressure, sealing pressure |

| Power supply | 24V, 12V |

| Output signal | 4~20mA, 1~5V, 0~10V |

| Working temperature | -20 ° C ~ 85 ° C |

| Medium temperature | -20 ° C ~ 85 ° C |

| Storage temperature | -40 ° C ~ 125 ° C |

| Zero temperature drift | ±1.5% FS (@-20°C~85°C) |

| Sensitivity temperature drift | ±1.5%FS (@-20°C~85°C) |

| Overload pressure | 150% FS |

| Mechanical vibration | 20g (20~5000HZ) |

| Impact | 100g (11ms) |

| Comprehensive accuracy | 0.5, 0.3 optional |

| Insulation | 100MΩ /250VDC |

| Response time | ≤ 1ms (up to 90% FS) |

| Long-term stability | ±0.2%FS/year |

| EMC Surge | (IEC61000-4-5) 2KV |

| EMC static | (IEC61000-4-2) contact discharge 8KV, air discharge 15KV |

| Protection level | IP65 |

| Explosion-proof grade | Intrinsically safe explosion-proof ExiaIICT4 |

| Material Housing | stainless steel; isolation diaphragm 316L |

| Media compatible | with a variety of media compatible with 316L stainless steel |

Read more about: What Is 0-10V Signal Output?

Applications of Pressure Transmitter 4-20mA

- Industrial OEM Equipment

- Water Management

- Pneumatics

- Hydrogen Storage

- Sub Sea Pressure

- HVAC/R Equipment

- Control Panels

- Hydraulic Systems

- Data Loggers

Extended reading: How to convert a 4-20mA to 0-10V /1-5V signal?

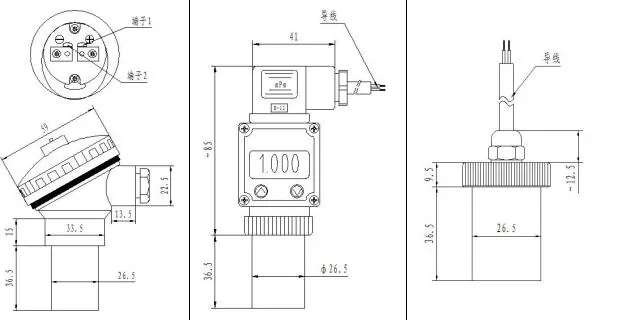

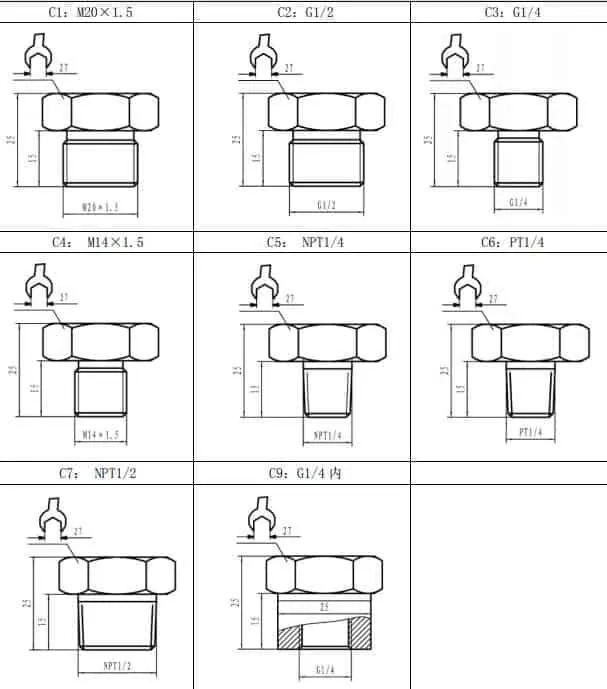

Drawings of SI-300 Pressure Transducer 4-20mA/Voltage

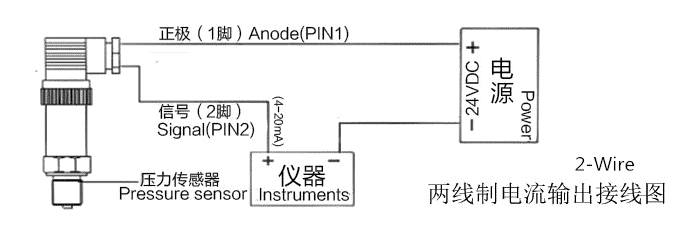

4-20ma pressure transducer wiring diagram

We offer OEM and Reseller Discounts for all kinds of 4-20mA pressure transducer

4-20ma differential pressure transmitter

Diaphragm seals 4-20ma pressure transducer

from entering into the pressure-sensing assembly of the Differential pressure, Gauge pressure,

orAbsolute pressure transmitter.

Industrial Pressure Transmitter

Sino-Instrument can offer industrial pressure transmitters with the display, 4-20ma output,

which can work as a natural gas pressure transducer,

water pressure transmitter, wastewater pressure transducer.

Submersible Pressure Transducer 4-20mA

is normal submersible pressure transmitter for level measurement.

Sino-Instrument Hydrostatic submersed level transducers are sensors,

with an electrical transmission output for indication of liquid level.

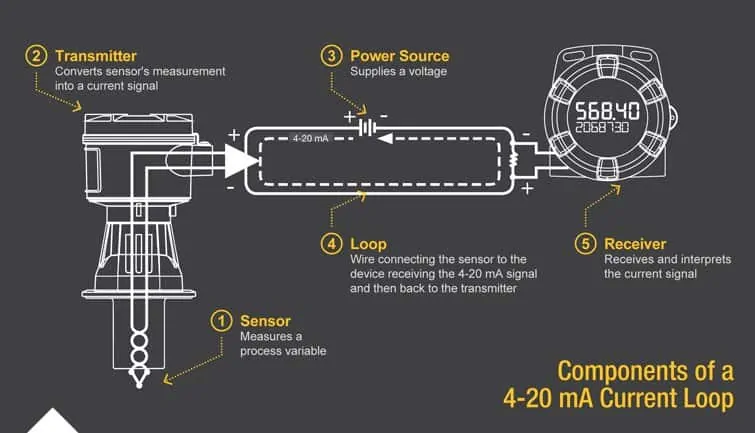

What is a 4-20mA Current Loop?

The 4-20 mA current loop is a process control signal commonly used in many industries.

This is an ideal method for transmitting process information. Because the current does not change when it flows from the transmitter to the receiver. It is also simpler and cost-effective. However, the number of voltage drops and process variables that need to be monitored can affect their cost and complexity.

By understanding these basics, you will be able to make more informed decisions about process control in your facility. This may affect your bottom line.

In order to understand what a 4-20 mA direct current (DC) loop is and how it works, we need to understand some math. Don’t worry we won’t study any advanced electrical engineering formulas.

In fact, the formula we need is relatively simple:

V = I x R This is Ohm’s law.

This means that the voltage (V) is equal to the current (I) times the resistance (R) (“I” stands for Intensitéde Courant, French for Current Intensity).

This is the basic equation in electrical engineering.

Consider the simple DC circuit above, which consists of one power supply and three loads.

The current loop requires voltage to drive the current. This is powered by the {PART 1} 12 power supply, which is labeled Vtot. Current then flows through the loop through each load. The voltage drop of each load can be calculated according to Ohm’s law.

The voltage drop V1 across R1 is:

Each element in the loop provides a voltage or has a voltage drop. However, currently, everything is the same in the loop.

This is the key principle of the 4-20 mA loop. The current is the same everywhere in the entire circuit.

It may be difficult to understand why the current stays constant, so compare your home’s water supply system.

There is a certain pressure in the water pipes that pushes the water towards the house. Voltage acts in a similar manner as pressure, pushing current through the circuit.

When the faucet in your home is turned on, the water runs down. The flow of water is similar to the flow of electrons or electricity. The ability of pressure to force water through a pipe is limited by the bending and restraint of the pipe. These limits limit the flow in the pipeline, similar to how resistors limit current.

Even if the pressure and voltage drop at various points, the flow through the pipeline and the current through the wires remain constant throughout the system.

This is why the use of current as a method of transmitting process information is so reliable.

Components of a 4-20 mA Loop

1. Sensor

2. Transmitter

3. Power Source

4. Loop

5. Receiver

Why we use the 4 20mA in transmitting signal?

Why is it 4/20 mA?

The reason for using a current signal is that it is less susceptible to interference. And the internal resistance of the current source is infinite. The wire resistance is connected in series in the loop without affecting the accuracy. And it can be transmitted over ordinary twisted pairs for hundreds of meters.

Due to explosion protection requirements, the upper limit is 20 mA: the spark energy caused by a current interruption of 20 mA is not sufficient to ignite the gas.

The reason why the lower limit is not set to 0mA is to detect a disconnection. During normal operation, the value will not be lower than 4mA. And when the transmission line is disconnected due to a fault, the loop current will drop to 0.

Usually, 20mA is used as the disconnection alarm value. There are two more reasons.

One reason is to avoid interference.

Another reason is that the two-wire system uses 4-20 mA of current. That is, the two wires are the signal line and the power line. The 4 mA is used to provide the quiescent operating current of the circuit for the sensor.

Extended reading: Smart Differential Pressure Transmitter

Pressure transmitter 4-20ma price

First of all, the parameters that must be seen when purchasing a pressure transmitter are:

Pressure range. Range. Measurement medium. Installation method-threaded flange clamps, etc. Installation dimensions. Temperature. Whether with display. Whether with HART protocol. Output type. Current output or voltage output. Explosion-proof level, protection level. Accessories. Mounting bracket.

The above parameters will affect the price of the pressure transmitter.

Sino-Inst, as the manufacturer of pressure transmitter, offer you with the best price.

Q&A

What does a pressure transducer do?

A pressure transducer is a device or device that can sense the pressure signal and convert the pressure signal into a usable output electrical signal according to a certain rule.

A pressure transducer usually consists of a pressure-sensitive element and a signal processing unit. According to different test pressure types, pressure sensors can be divided into gauge pressure sensors, differential pressure sensors and absolute pressure sensors.

Pressure transducer is the most commonly used sensor in industrial practice. It is widely used in various industrial automatic control environments, including water conservancy and hydropower, railway transportation, intelligent buildings, production automatic control, aerospace, military, petrochemical, oil wells, electricity, ships, machine tools , Pipelines and many other industries.

How do you test a 4 20ma pressure transducer?

Pressure transducer is a commonly used pressure instrument, which has certain applications in many industries. When a user detects a pressure transducer, the detection items are different depending on the purpose. Of course, the detection methods will be different. I will introduce 3 common methods for pressure transducer detection, and I hope it can help everyone.

1. Pressure test.

The detection method is: power the sensor. Use your mouth to blow the air holes of the pressure sensor. Use the multimeter’s voltage range to detect the voltage change at the output of the sensor. If the relative sensitivity of the pressure sensor is large, this amount of change will be significant. If nothing has changed, you need to use a pneumatic source instead.

Through the above methods, the condition of a sensor can be basically detected. If accurate testing is required, a standard pressure source is required. Apply pressure to the sensor and calibrate the sensor according to the pressure and the change of the output signal. When conditions permit, temperature detection of relevant parameters is performed.

2. Detection of zero point.

Use the multimeter’s voltage range. Detects the zero output of the sensor without applying pressure. This output is typically a mV level voltage. If it exceeds the sensor specifications. It means that the zero deviation of the sensor is out of range.

3. Detection of bridges.

The main test circuit of the sensor is correct. It is generally a Wheatstone full-bridge circuit, which uses the ohm range of a multimeter to measure the impedance between the input terminals and the impedance between the output terminals. These two impedances are the input and output impedances of the pressure sensor. If the impedance is infinite, the bridge is disconnected. It indicates that there is a problem with the sensor or the definition of the pins is not judged correctly.

What is a low pressure transducer?

Low pressure transducers for air and non-corrosive gases low pressure measurement.

Low pressure transducers also called low pressure transmitters. Sino-Inst offers High-precision low-pressure pressure transducers. 0 ~ 2.5kPa to 0 ~ 30kPa measurable. Low pressure transducer converts the measured pressure into an accurate electrical signal. This process is achieved through a high-performance amplifier circuit. The unique design of this product makes it unique in terms of environmental resistance. It is less affected by temperature changes. Anti-vibration With good long-term stability. Low pressure tranducers are suitable for applicaitons like: Liquid level. Flood warning. Waste water. Clean room. And open channel flow applications.

More about low pressure transducer.

What is the difference between transmitter and transducer?

A pressure sensor is a device or device that can sense a pressure signal and convert the pressure signal into a usable output electrical signal according to a certain rule.

A pressure sensor usually consists of a pressure-sensitive element and a signal processing unit. According to different test pressure types, pressure sensors can be divided into gauge pressure sensors, differential pressure sensors and absolute pressure sensors. A pressure sensor is the core part of pressure transmitter.

In a pressure transducer, a thin-film or piezo-resistive pressure sensor is mounted on a process connection. The transducer converts pressure into an analog electronic output signal, typically as a millivolt per volt output. These signals are not linearized or temperature compensated.

A pressure transmitter has additional circuitry that linearizes, compensates, and amplifies the signal from a transducer. The different signal types are typically voltage signals (eg, 0 to 5 or 0 to 10 volts), milliamp (eg, 4 to 20 milliamp), or digital. The instrument then can transmit the signal to a remote receiver.

Sino-Instrument offers over 50 pressure transducers 4-20mA/Voltage.

About 50% of these are 4-20ma differential pressure transmitters, 40% are Differential Pressure Gauge, and 20% are Diaphragm Seal Pressure transmitters, 20% are 4-20ma pressure transducer wiring diagram.

A wide variety of pressure transducers 4-20mA options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of pressure transducers 4-20mA, located in China.

The top supplying country is China (Mainland), which supply 100% of

pressure transducers 4-20mA respectively.

Sino-Instrument sells through a mature distribution network that reaches all 50 states and 30 countries worldwide.

Pressure Transducer 4-20mA/Voltage products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Current Output, 4 – 20 mA Transmitters

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.