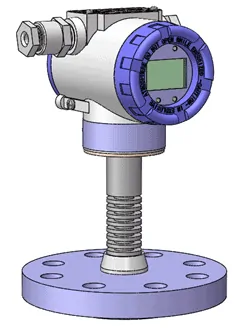

SMT3151TLT Pressure Level Transmitter is an economical flange direct-mounted pressure transmitter. An isolation diaphragm box is added as the measuring liquid contact part. One port is connected to the process tank (or pipeline) by flange (or other connection method).

Mainly used to measure high-temperature, easy to solidify or crystallize, containing suspended solids, too viscous, corrosive or other media that need to maintain sanitary conditions and cannot be contaminated.

Sino-Inst offers a variety of Diaphragm Seal Pressure Transmitters for industrial pressure measurement. If you have any questions, please contact our sales engineers.

Features of Pressure Level Transmitter

- Diffusion silicon isolation sensor

- Flange installation

- Large size diaphragm, fully welded and sealed, long-term reliable and durable

- Aluminum alloy junction box with strong seal and good outdoor installation

- Used for pressure measurement of gas, liquid and steam

- Anti-corrosion metal diaphragm optional

- With LCD display optional

- Especially suitable for high temperature or viscous liquid

- The flange size is customized according to customer requirements. And the installation is flexible and diverse

Read more about Steam pressure transmitter-Pressure measure on steam pipeline

Specifications of Pressure Level Transmitter

| Model | Transmitter type | |

| SMT-3151TLT | Flange level transmitter | |

| Code | Scale range | |

| 2 3 4 5 | 0-20~100kPa(0-2000~10000mmH2O) 0-70~350kPa(0-7~35mH2O) 0-200~1000kPa(0-20~100mH2O) 0-700~3500kPa(0-70~350mH2O) | |

| Code | Output form | |

| E | Linear output 4-20mAdc | |

| SF | Linear output 4-20mAdc+HART signal,Full function buttons on site | |

| F | MODBUS-485 signal | |

| Code | Flange standard (high pressure side flange) | |

| A | ANSI American Standard (HG20615) | |

| D | DIN European standard(HG20592) | |

| Code | Process connection size | |

| ANSI American Standard (HG20615) | DIN European standard(HG20592) | |

| 25 | 1″ | DN25 |

| 40 | 1.5″ | DN40 |

| 50 | 2″ | DN50 |

| 80 | 3″ | DN80 |

| 00 | 4″ | DN100 |

| Code | Process connection withstand voltage rating | |

| ANSI American Standard (HG20615) | DIN European standard(HG20592) | |

| A | 150LB | PN16/25 |

| B | 300LB | PN40 |

| C | 600LB | PN64 |

| D | 900LB | PN100 |

| Code | Measuring diaphragm | |

| A | 316 Stainless steel | |

| B | Hastelloy C | |

| C | Monel | |

| D | Tantalum | |

| E | Titanium | |

| F | Special requirements | |

| Code | Insert barrel length | Insert barrel material |

| A | 0 mm | None |

| B | 50 mm | 316L Stainless steel |

| C | 150 mm | 316L Stainless steel |

| D | 200 mm | 316L Stainless steel |

| Code | Filling liquid | |

| D | Ordinary silicone oil (-40~104℃) | |

| F | High temperature silicone oil (-40~304℃) | |

| S | Inert liquid (-40~204℃) | |

| Code | Shell material | Conduit inlet dimensions |

| A | Low copper aluminum alloy polyurethane coating | M20×1.5 |

| B | Low copper aluminum alloy polyurethane coating | 1/2-14 NPT |

| C | Stainless steel | M20×1.5 |

| D | Stainless steel | 1/2-14 NPT |

| Code | Optional parts | |

| M1 | 0~100% Linear indicator | |

| M4 | LCD Multi-function digital display | |

| Da | Flameproof ExdIIBT5Gb;(explosion-proof certificate No. : CE16.1163) | |

| Fa | Intrinsically safe ExiaIICT4 / T5 / T6Ga;(explosion-proof certificate No. : CE15.2354X) | |

| CX | With corresponding 316 flushing ring |

You may like: Explosion Proof Pressure Transmitter for Hazardous locations

Applications for Pressure Level Transmitters

The application which is suitable for diaphragm seal system… For measuring the liquid level, density, flow, and pressure of :

- High/low temperature fluids

- Highly corrosive/high viscosity fluids

- The fluids which may cause clogging of impulse piping in the low temperature

- Toxic fluids

- The fluids containing suspended solids which are deposited in the impulse piping and may cause clogging.\

Extended reading: Featured Diaphragm Seal Pressure Transmitters

Diaphragm flange material selection

The biggest advantage of the Diaphragm Seal Pressure Level Transmitter is that different diaphragm materials can be selected. According to different corrosion, media to achieve the best corrosion resistance. The commonly used diaphragm materials are SUS316L stainless steel. Tantalum, Hastelloy, Monel, Pure titanium, F4, etc.

When choosing a diaphragm pressure transmitter, in addition to the correct choice of structure and range, the more important thing is to choose the material. The so-called reasonable is to consider its corrosion resistance, but also to consider the economy. For example, the corrosion resistance of the tantalum diaphragm and Hastelloy is excellent, but it is expensive. Only used in environments with high corrosivity and other cheap materials are not suitable.

The following table introduces several common corrosion-resistant materials that can be selected for corrosion media. For your reference.

| Corrosive medium | Tin bronze (QSn6.5-0.4) | SUS316 | Pure tantalum (Ta) | Monel (Ni70Cu30) | Hastelloy (HC) | Polytetrafluoroethylene (F4) |

| Sulfuric acid (H2SO4) | V | △ | ○ | V | V | V |

| Nitric acid (HNO3) | ╳ | V | ○ | ╳ | V | V |

| Hydrochloric acid (HCI) | △ | ╳ | ○ | ╳ | V | V |

| Phosphoric acid (H3PO4) | V | V | ○ | V | V | V |

| Acetic acid (CH3COOH) | V | V | ○ | V | ○ | V |

| Caustic soda (NaOH) | △ | ○ | △ | ○ | ○ | V |

| Soda ash (Na2CO3) | ○ | ○ | ○ | ○ | V | V |

| Baking soda (NaHCO3) | V | ○ | ○ | ○ | ○ | V |

| Chlorine (CI) | Dry: V | Dry: V | ○ | Dry: V | V | V |

| Wet: ╳ | Wet: ╳ | Wet: ╳ | ||||

| Bromine (Br2) | Dry: △ | Dry: ╳ | ○ | Dry: ○ | ○ | V |

| Wet: ╳ | Wet: △ | Wet: ╳ | ||||

| Ammonia (NH3) | ╳ | V | ╳ | ╳ | ○ | V |

| Seawater (30% NaCI) | V | V | ○ | ○ | ○ | V |

Extended reading: Common Pressure Sensor Applications

What is diaphragm seal pressure transmitter?

The diaphragm seal pressure transmitter is the flange type pressure transmitter. This type of pressure transmitter, assembling diaphragm seals to field transmitters for the purpose of measuring pressure, differential pressure, level, and flow.

What is a diaphragm seal?

Diaphragm Seals, also known as Chemical Seals or Gauge Isolators, are used to isolate pressure instrumentation, like pressure gauges, pressure transmitters, pressure switches, level transmitters, and more from process media that is hot, corrosive, clogging, or otherwise damaging to the pressure instrument.

A diaphragm seal has two primary tasks:

- Separation of the measuring instrument from the process medium

- Transfer of the pressure to the measuring instrument

You may like: Diaphragm pressure gauge

What is remote seal?

The remote seal is used to prevent the medium in the pipeline from directly entering the pressure sensor assembly in the pressure transmitter. It is connected to the transmitter by a capillary filled with fluid. As a result, they’re often used in refining, petrochemical, and chemical plants.

Extended reading: SI-703 Flush Diaphragm Pressure Sensor

More Pressure Measurement Solutions

- 0-10v Pressure Transducers | 3 or 4 Wire Configuration

- Unraveling the Pressure Puzzle: Absolute Pressure vs Gauge Pressure

- Exploring Common Units of Pressure: A Comprehensive Guide

- Small Pressure Transducer/Sensor-Low Cost-High Performance

- What’s the Difference Between a Pressure Transducer and a Pressure Switch?

- What Is Flush Diaphragm Pressure Transducer? When Use?

- Natural Gas Pipeline Monitoring: Pressure-Temperature-Flow

- Different Types of Pressure: Absolute, Gauge, Sealed Gauge and Differential Pressure

FAQ

Sino-Inst is a Pressure Level Transmitters manufacturer in China.

We offer all types of Pressure Level Transmitters. Like Direct Mounted, flange-mounted, single flange, double flange, Remote Diaphragm Seals, High Static, Digital Remote.

Most of our Pressure Level Transmitters are used in oil, liquids, DP transmitter, flow measurement, level measurement (like the ultrasonic level measurement), density, and other process variables.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification. We will share more about instrument calibration, like the flow transmitter calibration.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.