Flush diaphragm pressure sensor is also called flush diaphragm pressure transducer or flush diaphragm pressure transmitter. Flush diaphragm pressure sensor has Flush membrane / diaphragm structure, anti-blocking design. Pressure measurement of viscous media.

Flush diaphragm pressure sensor uses a diaphragm isolation process. Feel the pressure directly with a flat membrane. There is no pressure hole in the test head. There is no clogging of viscous media during the measurement. Adopting flush membrane structure, diffused silicon pressure-sensitive core body, with good moisture resistance and excellent media compatibility. The sensor interface is available in clamp, thread and flange options. The output signal can be selected from voltage, current, and so on. The flush diaphragm of the sensor prevents problems such as scaling, unsanitary and clogging of viscous liquids.

Sino-Inst offers a variety of Flush diaphragm pressure sensors for industrial pressure measurement. If you have any questions, please contact our sales engineers.

Features of SI-703 Flush diaphragm pressure sensor

- The imported resistance strain gauge is used as a pressure-sensitive chip. The anti-blocking design of the flush membrane / diaphragm structure can measure viscous media.

- Advanced patch technology and process;

- It can bear large impact pressure, and the bearing pressure can reach 100MPa;

- The temperature drift is small, and it can work stably at the working temperature of -20 ~ 85 ℃ for a long time;

- The elastomer is also connected to the joint using a fully sealed or integrated structure. Solve the oil / gas shortcomings of diffused silicon and ceramic core pressure sensor cores. Reliable work and high fatigue strength;

- It is specially designed for OEM processing of pressure transmitter manufacturers. Low cost. Suitable for mass production;

Specifications of SI-703 Flush diaphragm pressure sensors

| Model | 703 Flush diaphragm pressure transmitter |

| Range | 0-0.6,1,5,10,20,30,40,50 ~ 200MPa |

| Comprehensive accuracy | 0.1% FS, 0.2% FS, 0.5% FS |

| Output signal | 4-20mA (two-wire system), 0-5 / 1-5 / 0-10VDC (three-wire system) |

| Supply voltage | 24VDC (10-30VDC) |

| Medium temperature | -20 ~ 75 ℃ |

| Ambient temperature | -20 ~ 75 ℃ |

| Load Resistance | Current output type: max. 800Ω; voltage output type: greater than 50KΩ |

| Insulation resistance | More than 2000MΩ (100VDC) |

| Sealing level | IP65 |

| Long-term stable performance | 0.1% FS / year |

| Vibration effect | Within the mechanical vibration frequency of 20Hz ~ 1000Hz, the output change is less than 0.1% FS |

| Electrical Interface | Metal sealed terminal, four-core aviation connector |

| Mechanical connection | M20 × 1.5, G1 / 2-14, etc., other threads can be customized |

| Model | 703F waterproof Flush diaphragm pressure sensor |

| Range | 0-1, 2, 4, 5, 10, 20, 30, 40, 50 to 200 MPa |

| Comprehensive accuracy | 0.2% FS, 0.5% FS, 1.0% FS |

| Output signal | 4-20mA (two-wire system), 0-5 / 1-5 / 0-10VDC (three-wire system) |

| Supply voltage | 24VDC (10-30VDC) |

| Medium temperature | -20 ~ 75 ℃ |

| Ambient temperature | -20 ~ 75 ℃ |

| Load Resistance | Current output type: max. 800Ω; voltage output type: greater than 50KΩ |

| Insulation resistance | More than 2000MΩ (100VDC) |

| Sealing level | IP65 |

| Long-term stable performance | 0.1% FS / year |

| Vibration effect | Within the mechanical vibration frequency of 20Hz ~ 1000Hz, the output change is less than 0.1% FS |

| Electrical Interface | Waterproof outlet |

| Mechanical connection | M20 × 1.5, G1 / 2-14, etc., other threads can be designed according to customer requirements |

| Model | 703K Flush diaphragm pressure sensor |

| Range | 0-2,1,5,10,20,30,40,50 ~ 100MPa |

| Comprehensive accuracy | 0.1% FS, 0.2% FS, 0.5% FS |

| Output signal | 1-1.5mV / V |

| Supply voltage | 10VDC |

| Medium temperature | -20 ~ 85 ℃ |

| Ambient temperature | -20 ~ 85 ℃ |

| Load Resistance | 1500Ω |

| Insulation resistance | More than 2000MΩ (100VDC) |

| Sealing level | IP65 |

| Long-term stable performance | 0.1% FS / year |

| Vibration effect | / |

| Electrical Interface | Direct outgoing |

| Mechanical connection | Φ19 standard size |

| Model | 703W Flush diaphragm micro pressure sensor |

| Range | 0, 1.5, 2, 10, 30, 50, 100-500KPa, 1-60MPa |

| Comprehensive accuracy | 0.25% FS, 0.5% FS |

| Output signal | 4-20mA (two-wire system), 0-5 / 1-5 / 0-10VDC (three-wire system) |

| Supply voltage | 24VDC (10-30VDC) |

| Medium temperature | -20 ~ 65 ℃ |

| Ambient temperature | Normal temperature (-20 ~ 65 ℃) |

| Load Resistance | Current output type: max. 800Ω; voltage output type: greater than 50KΩ |

| Insulation resistance | More than 2000MΩ (100VDC) |

| Sealing level | IP65 |

| Long-term stable performance | 0.1% FS / year |

| Vibration effect | Within the mechanical vibration frequency of 20Hz ~ 1000Hz, the output change is less than 0.1% FS |

| Electrical Interface | Hessman connector, other optional |

| Mechanical connection | M24 * 1.5, M25 * 1.5, M27 × 2, etc. Other threads can be designed according to customer requirements |

| Model | 703C Flush diaphragm micro pressure sensor |

| Range | 0-10, 30, 50, 100 ~ 500KPa, 1-7MPa |

| Comprehensive accuracy | 0.1% FS, 0.2% FS, 0.5% FS |

| Output signal | 4-20mA (two-wire system), 0-5 / 1-5 / 0-10VDC (three-wire system) |

| Supply voltage | 24VDC (10-30VDC) |

| Medium temperature | -20 ~ 65 ℃ |

| Ambient temperature | -20 ~ 65 ℃ |

| Load Resistance | Current output type: max. 800Ω; voltage output type: greater than 50KΩ |

| Insulation resistance | ≥2000MΩ (100VDC) |

| Sealing level | IP65 |

| Long-term stable performance | 0.1% FS / year |

| Vibration effect | Within the mechanical vibration frequency of 20Hz ~ 1000Hz, the output change is less than 0.1% FS |

| Electrical Interface | Hessman connector, four-core aviation connector optional |

| Mechanical connection | M20 × 1.5, G1 / 2-14, etc. |

| Model | 703G Flush diaphragm pressure sensor (Alternative WiKa similar products) |

| Range | 0 ~ 5, 10, 20, 50, 100-500KPa, 1-7MPa |

| Comprehensive accuracy | 0.1% FS, 0.2% FS, 0.5% FS |

| Output signal | 4-20mA (two-wire system), 0-5 / 1-5 / 0-10VDC (three-wire system) |

| Supply voltage | 24VDC (10-30VDC) |

| Medium temperature | -20 ~ 65 ℃ |

| Ambient temperature | Normal temperature (-20 ~ 65 ℃) |

| Load Resistance | Current output type: max. 800Ω; voltage output type: greater than 50KΩ |

| Insulation resistance | More than 2000MΩ (100VDC) |

| Sealing level | IP65 |

| Long-term stable performance | 0.1% FS / year |

| Vibration effect | Within the mechanical vibration frequency of 20Hz ~ 1000Hz, the output change is less than 0.1% FS |

| Electrical Interface | Hessman connector, other optional. |

| Mechanical connection | M20×1.5,G1/2-14 |

| Model | 703GB Flush diaphragm pressure sensor (Alternative WiKa similar products) |

| Range | 0 ~ 5,10,20,50,100KPa ~ 1MPa, 2,3,10MPa |

| Comprehensive accuracy | 0.1% FS, 0.2% FS, 0.5% FS |

| Output signal | 4-20mA (two-wire system), 0-5 / 1-5 / 0-10VDC (three-wire system) |

| Supply voltage | 24VDC (10-30VDC) |

| Medium temperature | -20 ~ 65 ℃ |

| Ambient temperature | Normal temperature (-20 ~ 65 ℃) |

| Load Resistance | Current output type: max. 800Ω; voltage output type: greater than 50KΩ |

| Insulation resistance | More than 2000MΩ (100VDC) |

| Sealing level | IP65 |

| Long-term stable performance | 0.1% FS / year |

| Vibration effect | Within the mechanical vibration frequency of 20Hz ~ 1000Hz, the output change is less than 0.1% FS |

| Electrical Interface | Hessman connector, other optional. |

| Mechanical connection | G1 |

Read more about: What is a pressure sensor and how it works?

SI-703 Flush diaphragm pressure sensor Applications

The sensor’s Flush diaphragm structure prevents problems such as scaling, unsanitation, and sticky liquid clogging. Widely used in food, pharmaceutical, brewing and other process control fields. It is suitable for the pressure measurement and control of viscous media such as chemical coatings, paints, muds, asphalts, and crude oil under weak pressure. Its industry applications are as follows:

- Food hygiene industry;

- Paper industry;

- Sewage level measurement;

- Beverage tank liquid level measurement;

- Pipeline level measurement;

- Pharmaceutical and biological products processing.

- Pressure transmitter manufacturer OEM

- Pressure measurement and control of viscous media

Extended reading: Flat Pressure Sensor for High Viscosity Fluids

Working Principle

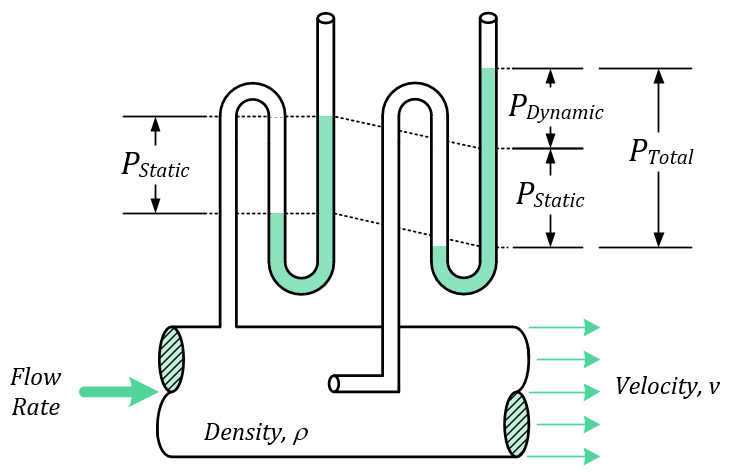

Flush diaphragm pressure sensors use processes such as diffusion or ion implantation to form resistors and connect them to a Wheatstone bridge. Micro-machining technology is used to form a pressure-sensitive diaphragm under the bridge. When pressure is applied to the diaphragm, the resistance value changes and a linearized output signal is generated that is proportional to the applied pressure. When we add DC power to the Wheatstone bridge, a DC voltage signal will be output. After the second conversion line, the two-wire system 4 ~ 20MA output is realized.

When to Use a Flush Diaphragm Pressure Connection?

In short, there are two cases, we can first consider Flush Diaphragm Pressure Connection.

The first is hygienic applications. Such as Pharmaceutical, Food, Beverage & Biotech.

For these applications the concern is not necessarily high viscosity but more to do with cleanliness. The wetted part of the Flush Diaphragm Pressure Sensor is flat. No holes, no ripples. This way, residue-free cleaning is easy.

The second is High Viscosity Liquids or Crystals.

Substances such as paints, oils, waxes, pastes, tars, plastic melts or slurries can clog the process connections of the pressure sensor.

The media may be too hard to adequately fill the internal voids of the pressure connector. Or once the process cools, the substance may wax. For these types of substances, it is necessary to specify a flushing connection in which the diaphragm is fully open.

Some pressure transducers have the option of flush-embedded diaphragms where mechanical damage to the diaphragm is a concern.

WIKA has a great video on When to use a front-flush pressure connection? Let’s take a look.

Technical Support

Frequently

Asked

Questions

Related Products

Sino-Inst offers Flush diaphragm pressure sensors. A wide variety of Flush diaphragm Pressure sensors options are available to you. Such as free samples, paid samples. Sino-Instrument is a globally recognized manufacturer of Flush diaphragm Pressure sensors, located in China.

Sino-Inst sells through a mature distribution network that reaches all 30 countries worldwide. Flush diaphragm Pressure sensors products are most popular in Europe, Southeast Asia, and Mid East. You can ensure product safety by selecting from certified suppliers. With ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.