Non Contact Level Transmitters are now more and more widely used in industrial level monitoring. We most often provide customers with non-contact radar level transmitters and ultrasonic level meters. Both liquids and solids can be measured with Non Contact Level Transmitters. There is no need to dig the level probe deep into the measured medium. The sensitive elements measured by Non Contact Level Transmitters are not in contact with the liquid being measured. It can be used in special occasions that contact measuring instruments cannot meet. Such as the medium with high viscosity, strong corrosiveness, strong pollution and easy crystallization.

Featured Non Contact Level Transmitters for Sale

Non Contact Level Transmitters Types

In order to choose the most suitable level sensor, we not only need to know the properties and state of the liquid being measured. It is also necessary to understand the advantages and disadvantages of different level sensors. in order to select the most suitable sensor. Next, let’s briefly introduce the common non-contact liquid level measurement methods and their characteristics.

Common non-contact measurement methods mainly include ray level meter, ultrasonic level meter, laser ranging sensor and radar level meter.

Radar Type Level Transmitter Working Principle

Very short microwave pulses with very low energy are transmitted and received through the antenna system. The radar wave runs at the speed of light. The operating time can be converted into level signals by electronic components. A special time extension method can ensure stable and accurate measurement in a very short time.

Electromagnetic waves propagate in the air at the speed of light. The distance between the radar level gauge and the surface of the material can be expressed by the following formula:

D = (1/2)*CT

In the formula:

D ———the distance between the radar level gauge and the surface of the material;

C ———Speed of light

T ———Pulse time.

Then the liquid level is: L = E-D

In the formula:

L — liquid level;

E ———The total height of the tank;

D ———Air height.

Even in the presence of false reflections, the new micro-processing technology and the unique ECHOFOX- software can accurately analyze the level echo. By inputting the size of the container, the distance value can be converted into a signal proportional to the level. The instrument can be debugged with empty positions.

Extended reading: Amazing Solutions for Continuous Liquid Level Measurement

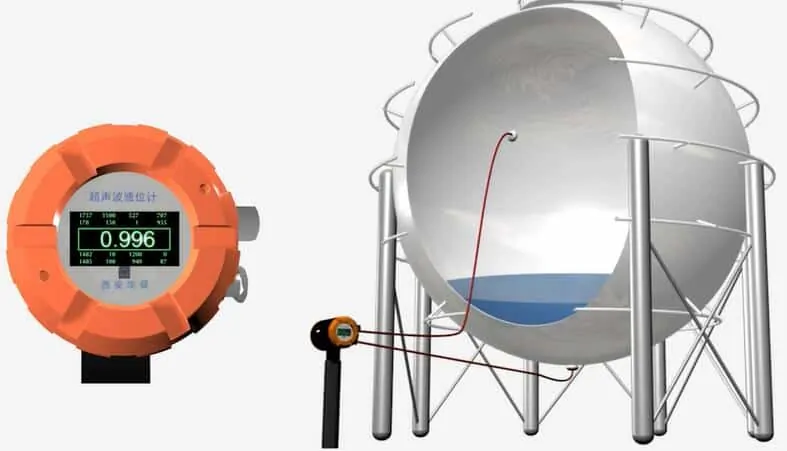

Ultrasonic Level Transmitter Working Principle

The working principle of the ultrasonic level sensor is:

Ultrasonic transducer (probe) emits high-frequency pulse sound waves, and the surface of the measured level (material) is reflected back. The reflected echo is received by the transducer and converted into an electrical signal. The propagation time of the sound wave is proportional to the distance from the sound wave to the surface of the object.

The relationship between the sound wave transmission distance S and the sound speed C and the sound transmission time T can be expressed by the formula: S=C×T/2.

The probe part emits ultrasonic waves, which are then reflected by the liquid surface. The probe part is received again. The distance from the probe to the liquid (object) surface is proportional to the elapsed time of the ultrasonic wave:

hb = CT2

Distance [m] = time × speed of sound/2 [m]

The temperature compensation formula of sound velocity:

Ambient sound velocity = 331.5 + 0.6 × temperature

Read More about: List of Differences: Radar vs Ultrasonic Level Measurement

Non Contact Level Transmitters Industrial Applications

Sino-Inst’s Non Contact Level Transmitters, whether ultrasonic level meter or radar level meter, are widely used in various industries.

Highly toxic medium

Bromine

liquid chlorine

Liquid ammonia

dimethyl ether

Oil, flammable and explosive media

gasoline and diesel

crude

heavy oil

Volatile media in pressure vessels

liquefied gas

C4

acrylic

liquified natural gas

Corrosive media

Anhydrous hydrogen fluoride

Bromine

Other media

methanol

fuel styrene

wax oil

Acetylene

- Chlor-alkali

- Storage and transportation

- petrochemical

- Coal chemical industry

- oil refining

- Fluorine chemical

- fertilizer

- pesticide

- electricity

- liquid storage

- other industry

Extended reading: Oil-water interface measurement-Magtech magnetic level indicator

More Non-Contact Liquid Level Measurement Solutions

Frequently

Asked

Questions

Read more about: River Water Level Monitoring System

Sino-Inst is Manufacturer of Non Contact Level Transmitters. We supply more than 20 kinds of Non Contact Level Transmitters. 40% ultrasonic level meters, 40% radar level transmitters and 20% other types of flowmeters.

Non Contact Level Transmitters are mainly used for level measurement of various liquids and solid particles.

It can measure even liquids such as water, seawater, oil, and slurry.

Non Contact Level Transmitters enable stable level measurement without tank modifications. This greatly meets the measurement needs of many applications. Can be used from small to large tanks.

Sino-Inst’s Non Contact Level Transmitters, made in China, Having good Quality, With better price. Our level measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

The entire team at Sino-Inst’s has received excellent training, so we can ensure that every client’s needs are met. For assistance with your product requirements, whether it’s a Non Contact Level Transmitters, flow sensor, or other device, give us a call.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.