Differential Pressure Gauge measures the pressure difference between two points. Quickly measure the positive, negative or DP of air or non-corrosive gas.

Differential pressure gauge measures the pressure difference between two independent pressure sources. Differential pressure gauge is a more economical method. Used for process monitoring or control, which allows a small amount of migration of process media. Suitable for air and non-flammable, non-corrosive applications. And certain air and natural gas applications. Using a simple, frictionless magnet spiral movement, it can quickly indicate the pressure of low pressure or non-corrosive gas. Whether positive, negative (vacuum is also available) or differential pressure. This design can prevent vibration, jitter, and overvoltage. No liquid needs to be filled in the watch.

Sino-Inst is a manufacturer of Differential Pressure Gauge. Sino-Inst supplies Differential Pressure Gauges made in China. DWYER 2000 Differential Pressure Gauges, Magnehelic differential pressure gauges are also available.

Features of Differential Pressure Gauge

- Up to 81 kinds of range selection, can accurately meet your requirements

- Using simple and unique patented double helix frictionless magnetic moving parts, you can quickly measure the positive pressure of air or non-corrosive gas, measure negative or differential pressure

- Designed to resist shock, shock and overload protection

- No liquid U-tube pressure gauge liquid evaporation, freezing, poisoning and leakage problems

- Can measure fan, blower, filter resistance, furnace ventilation, orifice plate

- Pressure drop and other system pressures. Can also be used in various purification rooms, biological safety

- Cabinet, clean bench, dust removal equipment, medical breathing equipment, air intake

- Sample differential pressure detection

- Up to 63 models with different ranges and engineering units, suitable for various applications

- Ultra-thin design: embedded thickness is only 38.5mm, overall thickness is only 52.2mm

- Patented wave stripe decorative mask, beautiful and elegant

- Standard accuracy up to 2%; after high precision calibration, up to 1% FS

- Optional mirror dial to eliminate visual reading error and brushed 304 SS or plated bezel

Specifications of Differential Pressure Gauge

- Accuracy: ±2% (ascending pressure)

- Pressure Ranges: 0-5 thru 0-150 psi

- Dial size: 2″, 2 1/2″, 3 1/2″, 4″, 4 1/2″ and 6″

- Case: stainless steel

- Body: aluminum, brass or stainless steel

- Wetted Material: body material, Teflon ®, ceramic and various O-ring materials

- Medium: air and non-flammable, compatible gas (optional natural gas)

- Shell: cast aluminum or ABS shell, plexiglass beveled panel. Dark gray coating for 168 hours salt spray test

- Withstand voltage range: -20Hg. to 15 psi (-0.677 bar to 1.034 bar)

- Temperature range: 20 to 140 °F (-6.67 to 60 °C)

- Opening size: 114mm

- Installation positioning: diaphragm for the vertical direction

- Connector: the same 1/8″ NPT high and low-pressure connector, one pair on the side and one pair on the back

- Weight: 500g / only

- Standard accessories:

- two 1/8″ NPT threaded joints for high and low-pressure joints and connected to rubber hoses;

- two 1/8″ NPT plugs for blocking the remaining two high and low-pressure ports;

- Three threaded countersunk mounting connectors (mounting ring, snap ring retainer are used to replace the three ports on the MP and HP metering accessories).

| RANGES FOR REFERENCE | Pa | Kpa | Inches of Water | MM of Water | Dual Scale |

| 0-30 | 0-0.5 | 0-.25 | 0-6 | in w.cc | Pa or Kpa |

| 0-60 | 0-1 | 0-.50 | 0-10 | 0-.25 | 0-62 Pa |

| 0-100 | 0-1.5 | 0-1.0 | 0-15 | 0-0.5 | 0-125 Pa |

| 0-125 | 0-2 | 0-2.0 | 0-25 | 0-1.0 | 0-250 Pa |

| 0-300 | 0-5 | 0-8.0 | 0-30 | 0-2.0 | 0-500 Pa |

| 0-500 | 0-8 | 0-10 | 0-50 | 0-3.0 | 0-750Pa |

| -30-0-30 | 0-10 | 0-20 | 0-80 | 0-4.0 | 0-1.0kPa |

| -60-0-60 | 0-20 | 0-50 | 0-100 | 0-5.0 | 0-1.25kPa |

| -100-0-100 | 0-30 | 0-100 | 0-125 | 0-6.0 | 0-1.5kPa |

| -250-0-250 | 0-50 | 0-180 | 0-200 | 0-8.0 | 0-2.0kPa |

| -500-0-500 | 0-60 | 0-250 | 0-300 | 0-0.5 | 0-2.5kPa |

You may like: Diaphragm Seal Pressure/ Differential Pressure Transmitters

What is a differential pressure gauge?

Differential pressure gauges are suitable for measuring small pressure differences between two pressure sources in an industrial process. Measure the pressure loss of the filter and observe the working state of the valve. It is widely used to measure the pressure of fan and blower, filter resistance, wind speed, furnace pressure, orifice differential pressure, bubble water level, liquid amplifier or hydraulic system pressure, etc. It is also used for air-gas ratio control and automatic valve control during the combustion process.

Differential pressure gauge is suitable for measuring the differential pressure, flow rate and other parameters of various liquid (gas) media in the process flow of industrial sectors such as chemical, chemical, metallurgy, electric power, and nuclear power. The instrument structure is all made of stainless steel. Among them, the measurement system (double bellows emergency connection parts) and the pressure guiding system (including joints, conduits, etc.) adopt special structure design and advanced technology.

Principle of differential pressure gauge

How does a differential pressure gauge work ?

Based on the pressure-sensitive element, two bellows with the same stiffness are used. Therefore, they are forced to produce the same concentrated force on the movable bracket under the same measured medium. Because the two sides of the spring sheet do not produce deflection under the action of equal moments. It is still in the original position. In this way, the gear transmission mechanism does not operate. The pointer is still at the zero position.

When different pressures are applied (generally the high-pressure end is higher than the low-pressure end), the forces of the two bellows acting on the movable bracket are not equal. The corresponding displacements are generated. The gear transmission mechanism is driven and amplified. The pointer deflection The latter indicates the differential pressure between the two.

Home > DP Transmitters > D2000 Differential Pressure Gauge

Differential Pressure Gauge Application

The SI-2000 differential gauge is ideal Where safe and reliable pressure measurement is essential:

- Filtration Monitoring

- Pressure Drop across a Strainer

- Flow Rate

Dwyer Magnehelic series 2000 differential pressure gauge

American Dwyer differential pressure gauge/ Dwyer 2000 differential pressure gauge

The Dwyer 2000 series differential pressure gauge is an ultra-low-range, inexpensive, and solid structure field indicator. It uses the frictionless Magnehelic movement principle to eliminate wear, hysteresis and gaps. Without liquid filling, it will not vaporize and freeze. It can quickly indicate the low pressure and non-corrosive gas (positive pressure, negative (vacuum) and differential pressure). There are 81 ranges, the minimum range is 0-60Pa, or 0-6mm water column or 0-0.25′ water column). This design has anti-vibration, shaking and high resistance to overpressure.

Main technical indicators of American Dwyer differential pressure gauge Dwyer 2000

- Accuracy: accuracy 2% FS (suffix 0 is 3%; suffix 00 is 4%) Rated pressure: -0.7 ~ 1Kg / cm

- Connection: 1/8 “NPT internal thread, two pairs of high and low pressure ports, on the side and back

- Overpressure: The vent will open automatically when it is about 1.75Kg / cm2

- Ambient temperature: -5 ℃ ~ 60 ℃, weight 0.5Kg

- Outer shell: cast aluminum outer shell, the main body and components pass the 168-hour salt spray test, and the exterior is dark gray coating.

- Standard accessories: two 1/8 “NPT threaded joints, used as high and low pressure joints and can be connected with rubber tubes; two 1/8” NPT plugs; three threaded countersunk fittings.

- According to the requirements of the National GMP Drug Production Verification Guidelines for clean workshops, we recommend selecting:

- Add positive micro-pressure (5-10Pa) to the workshop or room, and select a 2000-60Pa micro differential pressure gauge.

- Check the filtering effect of coarse, medium and high-efficiency air filters, use differential pressure gauges such as 2000-125, 250Pa, 500Pa or 1Kpa, and observe the pressure difference of the filter at any time to replace the filter.

Scope and model:

2000-60PA 0-60Pa,

2300-120PA, 0- ± 60Pa,

2000-125PA0, -125Pa,

2300-250PA, 0– ± 125Pa,

2000-125PA, 0-250Pa,

2300-500PA, 0- ± 250Pa,

2000-500PA, 0-500Pa,

2000-750PA, 0-750Pa

81 range specifications including 2000-30KPA.

Sino-Inst provides DWYER differential pressure gauge, micro differential pressure gauge, mechanical differential pressure gauge including MAGNEHELIC 2000 series. All products can be ordered, domestic brands include: MACROHELIC and MAGRFHELIC, price concessions, spot supply.

Differential pressure gauge price

Reference Price:

Dwyer 2000 series differential pressure gauge: USD 75.00 / pc

SI-2000 Differential Pressure Gauge: USD49.50 / pc

The exact price needs to be determined according to the product parameters and the quantity purchased.

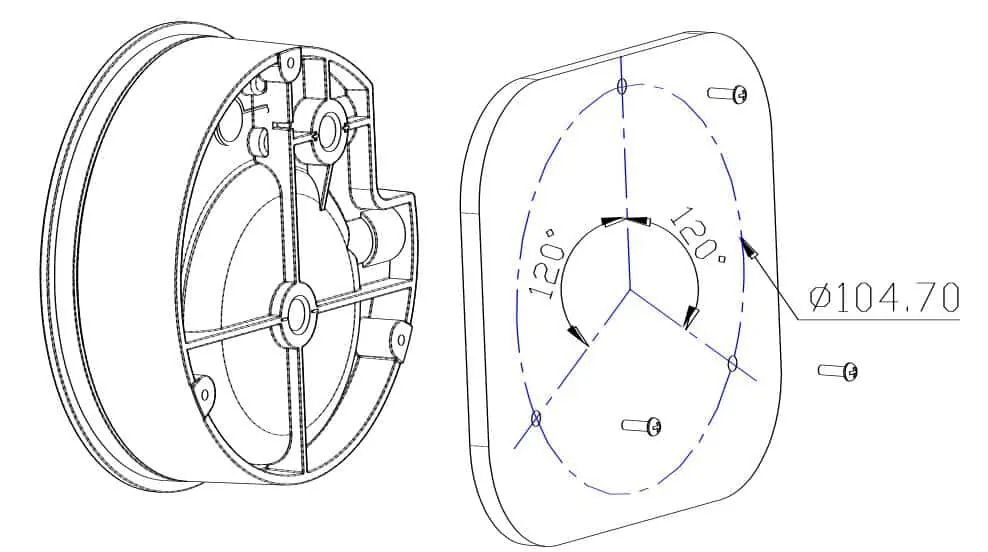

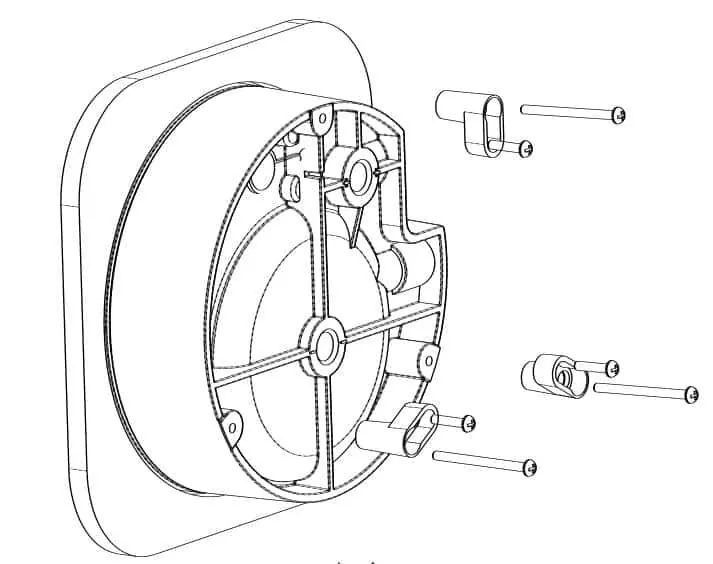

Differential pressure gauge installation

1-Surface Mount

(1) Installation method one, as shown in the following picture 1. Drill three installation vias with an angle of 120 degrees and a diameter of 4.5mm on the installation plane. Use the corresponding short installation screws in the accessory package to match the screw holes on the bottom of the instrument. Make it secure .

(2) Mounting method two, as shown in the following figure 2. Take three mounting brackets first. Use the corresponding installation short screws in the accessory package. Fix the mounting bracket to the three mounting screw holes on the bottom of the instrument. Then take the longest three screws. Lock with the installation plane

2-Embedded (panel) installation

Cut the installation and insertion holes with a diameter of 115.5mm on the panel. Insert the meter into the holes. See Figure 3 below. Take three mounting brackets, and use the corresponding installation short screws in the accessory package. Fix the mounting bracket to the three mounting screw holes on the bottom of the meter. Then take the longest three screws. Fasten the meter to the panel.

3-Embedded (color steel plate) installation

Cut the embedded hole with a diameter of 115.5mm on one side of the color steel plate. As shown in figure 4 below, install the A-S1 / S2 panel into the color steel plate.

The pressure port on the back of the meter is firmly installed. Among them, accessories A-S1 / S2 and A-S81 need to be purchased separately.

4-For other installation methods. see the following figure 5. Use special screws A-S9 to fix the installation with the pressure interface on the back of the instrument. Accessories A-S9 need to be purchased separately.

5-Zero adjustment

After installing the instrument, adjust the zero position. Using a suitable flat-blade screwdriver, turn the zero adjustment screw at the bottom of the transparent mask counterclockwise. Align the pointer with the zero position of the dial. During zero adjustment, both the high-pressure port and the low-pressure port can communicate with the atmospheric pressure.

6-Pressure connection

With the standard configuration accessories, according to actual needs, correctly connect the “+” and “-” pressure ports. Note that the instrument has a pair of pressure ports on the side and back. The unused pair of plug seals in the application accessories.

FAQ

Two pressure ports for L (low pressure) and H (high pressure). Different connections can quickly indicate gas pressure. Including positive, negative or differential pressure. Zero calibration can be directly operated externally.

Pressure measurement: Connect the pressure source to any one of the two high-pressure ports with an air pipe, and block the unused one; make one or two low-pressure ports open to the atmosphere.

Differential pressure measurement: Connect the high-pressure source to any one of the two high-pressure ports with an air pipe, and connect the low-pressure source to any one of the two low-pressure ports with an air pipe; block the two pressure ports that are not used on the meter.

Negative pressure measurement: Connect the pressure source to any one of the two low-pressure ports with an air duct, and block the unused one; make one or two high-pressure ports open to the atmosphere.

Send to Calibration Institute for calibration. Self-calibration requires equipment and qualifications, otherwise it will not be recognized.

If no report is required, you can calibrate yourself:

First, at least one certified high-precision micro-pressure gauge or pressure gauge is required as a reference standard. Then select 5-7 points in the full range and give a fixed pressure difference at both ends of the differential pressure gauge. If it is a micro differential pressure gauge, you can use a micro pressure pump to give pressure to the high pressure port. If it is a large number of differential pressure gauges, you can use a liquid pump to give pressure to the high-pressure port. Then observe the reading between the reference standard and the differential pressure gauge, record and calculate the relative error.

The role of the pressure gauge is used to measure and indicate the size of the pressure in the pressure product. If the pressure product does not have a pressure gauge, or if the pressure gauge fails, the pressure of the pressure product cannot be expressed. This directly threatens safety.

A sensitive and accurate pressure gauge is installed on the pressure product. The operator can operate the pressure product correctly with the pressure gauge to ensure safe and economical operation.

The pressure gauge can accurately indicate the level of the steam pressure in the pressure product. The operator can adjust the heating degree of the product according to the indicated value of the pressure gauge. In order to ensure the requirements of the gas department and the safe operation of pressure products.

Sino-Instrument offers over 50 Differential Pressure Gauge products. About 50% of these are differential pressure meters, 40% are water meters, and 40% are level meters.

A wide variety of Differential Pressure Gauge options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of Differential Pressure Gauge, located in China.

The top supplying country is China (Mainland), which supply 100% of Differential Pressure Gauge respectively.

Sino-Instrument sells through a mature distribution network that reaches all 50 states and 30 countries worldwide. Differential Pressure Gauge products are most popular in Domestic Market, Southeast Asia, and Mid East. You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Request a Quote

-

Oem smart Pressure Transducer pressure sensor

-

Silicon Pressure Transmitter

-

Oem smart Pressure Transducer pressure sensor

-

Explosion-proof electronic pressure transmitter

-

SMT3151 Diaphragm Seal Pressure transmitter

-

Submersible level transmitter

-

static pressure transmitter

-

smt3151gp-ap-pressure-absolute-pressure

-

high temperature transmitter

-

SMT3151 TGP -stainless steel sensor process, oil and gas industry

-

3151 dp transmitters manufacturer

-

SMT3151 differential pressure level transmitter

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

high temperature transmitter

high temperature transmitter