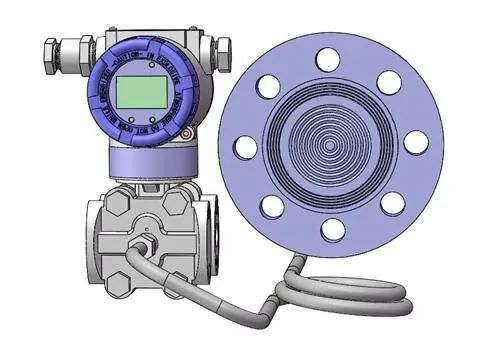

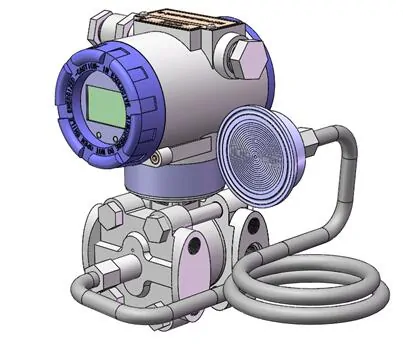

Remote seal pressure transmitter, with capillary and diaphragm seal, remote mount. Diaphragm seal systems protect pressure transmitters from hot, viscous, contaminated or corrosive media.

Remote Diaphragm seal pressure transmitter with capillary is used as a level transmitter. Diaphragm Seals also called chemical seals, are used in applications where pressure sensor requires isolation from the process media. These applications are corrosive, high temperature, clogged. Or must sanitary fluids to remain in the pipeline or container. The pressure of the liquid in the process does not affect the pressure sensor. Instead, it is applied to the remote seal. And through the capillary, hydraulic pressure is transmitted to the pressure sensor. Installing and filling the diaphragm seal, the impact on instrument performance will be minimized.

Sino-Inst also offers repair, refurbishment or replacement of used transmitters with remote seals.

Features of Remote Diaphragm Seal Pressure Transmitter

Protect pressure sensor

The remote transmission diaphragm can protect the transmitter diaphragm from corrosive, aggressive or extreme temperature.

Various sealing diaphragms are available

Sino-Inst can provide a suitable sealing diaphragm according to your measurement requirements. For example, remote threaded seal, flush flanged type seals, remote flange seal-RTJ gasket surface, extended flanged seal, etc.

Suitable for special environments.

Such as:

High / low temperature fluids;

Highly corrosive / high viscosity fluids;

Toxic fluids;

The fluids containing suspended solids which are deposited in the impulse piping and may cause clogging.

Specifications of Remote Diaphragm Seal Pressure Transmitter

| Measurement parameters: | pressure, liquid level |

| Measuring range: | lower limit: -100% URL (continuously adjustable); upper limit: to + 100% URL (continuously adjustable) |

| Output: | two-wire system, 4-20mADC + HART output, digital communication; output signal limit: Imin = 3.9mA, Imax = 20.5mA |

| Alarm current: | ①Low report mode (minimum): 3.7mA ②High report mode (maximum): 21mA ③No report mode (hold): keep the effective current value before the fault ④Alarm current standard setting: high report mode |

| Response time: | the damping constant of the amplifier part is 0.1s; the time constant of the sensor and the remote flange is 0.2-6s, which depends on the range of the sensor, the range ratio, the length of the capillary, and the viscosity of the filling fluid The additional adjustable time constant is: 0.1-60s. |

| Ambient temperature: | minimum: depends on the filling liquid; maximum: 85 ℃; with liquid crystal display, fluorine rubber sealing ring is -20 ~ +65 ℃ |

| Storage temperature / transport temperature: | minimum: depends on filling liquid; maximum: 85 ℃ |

| Relative humidity: | 0-100% |

| Anti-shock: | acceleration: 50kg; duration 11ms |

| Anti-vibration: | 2g to 500Hz |

| Process medium temperature limit: | medium temperature: -20 ~ 400 ℃ |

| Pressure limit of transmitter body: | vacuum to maximum pressure |

| Rated pressure of remote flange: | ANSI standard: 150psi-600psi; DIN standard: PN1.6MPa-PN10MPa |

| Warm-up time: | <15s |

| Explosion-proof performance: | NEPSI explosion-proof license: ExdⅡCT6; NEPSI intrinsically safe license: ExiaⅡCT4; allowable temperature is -40 ~ + 65 ℃ |

| Power and load conditions: | ① The power supply voltage is DC24V, R≤ (Us-12) / Imax kΩ, where Imax = 23mA ②Max power supply voltage: 42VDC ③Minimum power supply voltage: 12VDC, 15VDC (backlit LCD display) ④Digital communication load range: 250-600Ω |

| Electrical connection: | M20 × 1.5 cable sealing buckle, the terminal is suitable for 0.5-2.5mm2 wire |

| Process connection: | The remote flange meets ANSI standard or DIN standard. Can be installed directly, please refer to the dimension drawing for flange size |

| Material: | Measuring capsule: stainless steel 316L; diaphragm: stainless steel 316L, Hastelloy C, tantalum |

| Process connection: | stainless steel 316 |

| Filling fluid: | silicone oil, high temperature silicone oil, ultra high temperature silicone oil, vegetable oil |

| Pressure transmitter shell: | aluminum alloy material, epoxy resin on the surface |

| Shell sealing ring: | NBR |

| Nameplate: | Stainless steel 304 |

| Weight: | DN50 / 2 inches about 7-10kg; DN80 / 3 inches about 8-11kg; DN100 / 4 inches about 9-12kg |

| Shell protection grade: | IP67 |

Read more What is a diaphragm seal?

Types of SMT3151 Remote Diaphragm Seal System Pressure Transmitters

3151T flange type remote pressure transmitter

The selection is as follows:

3151TGP4SF00S1M4B4 0~40kPa

1199FFW A50AADL03H00

On behalf of the 3151TGP base table plus an American standard 2”150LB flange type remote transmission device, the capillary length is 3 meters.

3151T flat remote pressure transmitter

The selection is as follows:

3151TGP4SF00S1M4B4 0~40kPa

1199PFWA50AADL03H00

On behalf of the 3151TGP base table plus an American standard 2”150LB flat remote transmission device, the capillary length is 3 meters.

3151T type insert barrel remote pressure transmitter

The selection is as follows:

3151TGP4SF00S1M4B4 0~40kPa

1199EFWA50AABDL03H00

On behalf of the 3151TGP base table plus an American standard 2”150LB plug-in remote transmission device, the capillary length is 3 meters, the insertion barrel length is 100mm.

3151T threaded remote pressure transmitter

The selection is as follows:

3151TGP7SF00S1M4B4 0~1000kPa

1199RTWA1AADL03H00

On behalf of the 3151TGP base table plus a threaded connection remote transmission device, capillary length of 3 meters, user connection thread specifications 1/2NPT-14.

3151T type three clamp type remote pressure transmitter

The selection is as follows:

3151TGP5SF00S1M4B4 0~100kPa

1199SCWA1A0DL03H00

On behalf of the 3151TGP base table plus a three-clamp type remote transmission device, the capillary length is 3 meters, the user connection clamp specification is 1 1/2 inch.

3151GP/DP flange type remote pressure transmitter

The selection is as follows:

3151GP4SF22S1M4B3 0~40kPa

1199FFW A50AADL03H00

On behalf of the 3151GP base table plus an American standard 2”150LB flange type remote transmission device, the capillary length is 3 meters.

3151GP/DP flat remote pressure transmitter

The selection is as follows:

3151GP4SF22S1M4B3 0~40kPa

1199PFWA50AADL03H00

On behalf of the 3151GP base table plus an American standard 2”150LB flat remote transmission device, the capillary length is 3 meters.

3151GP/DP type insert barrel remote pressure transmitter

The selection is as follows:

3151GP4SF22S1M4B3 0~40kPabr>

1199EFWA50AABDL03H00

On behalf of the 3151GP base table plus an American standard 2”150LB plug-in remote transmission device, the capillary length is 3 meters, the insertion barrel length is 100mm.

3151GP/DP type threaded remote pressure transmitter

The selection is as follows:

3151GP7SF22S1M4B3 0~1000kPa

1199RTWA1AADL03H00

On behalf of the 3151GP base table plus a threaded connection remote transmission device, capillary length of 3 meters, user connection thread specifications 1/2NPT-14 specific size,

3151GP/DP type three clamp type remote pressure transmitter

The selection is as follows:

3151TGP5SF22S1M4B3 0~100kPa

1199SCWA1A0DL03H00

On behalf of the 3151GP base table plus a three-clamp type remote transmission device, the capillary length is 3 meters, the user connection clamp specification is 1 1/2 inch.

Diaphragm Seal System

Remote Diaphragm seal pressure transmitter, is the capillary type pressure transmitter. This type pressure transmitter, assembling diaphragm seals to field transmitters for the purpose of measuring pressure, differential pressure, level, and flow.

Diaphragm seals are used to prevent process medium from entering into the pressure-sensing assembly of the Differential pressure, Gauge pressure, or Absolute pressure transmitter.

Applications which is suitable for diaphragm seal system

- For measuring the liquid level, density, flow and pressure of ;

- high/low-temperature fluids;

- highly corrosive/high viscosity fluids ;

- the fluids which may cause clogging of impulse piping in the low temperature ;

- toxic fluids;

- the fluids containing suspended solids, which are deposited in the impulse piping and may cause clogging.

You may like: Diaphragm pressure gauge

How do diaphragm seals work?

Basically, diaphragm seals are used in all pressure measurement processes to avoid direct contact between the measuring instrument and the medium during this process. In addition, if the measuring point cannot be installed or read because the measuring point is located in a hard-to-reach location, a diaphragm seal can also be used. In both cases, the applied pressure is transferred to the measuring instrument through the system fill fluid in the diaphragm seal housing.

The diaphragm of the seal can be made of different materials, such as stainless steel, Hastelloy, Monel or tantalum. In addition, coatings with ECTFE, PFA or gold can also be used.

We can provide the best diaphragm seal design, materials, system fill fluid and accessories for each application. The combined configuration of the pressure measuring instrument and the diaphragm seal is mainly determined by the special application conditions of the diaphragm sealing system.

How does a diaphragm pressure sensor work?

When the diaphragm seal pressure transmitter is working, the high and low pressure side isolation diaphragms and the filling liquid transfer the process pressure to the center filling liquid. The filling fluid in the center transmits the pressure to the sensing diaphragm in the center of the δ-chamber sensor. The sensing diaphragm is a tensioned elastic element, and its displacement changes with the differential pressure. For GP gauge pressure transmitters, the atmospheric pressure is applied to the low-pressure side of the sensing diaphragm. AP absolute pressure transmitter, the low pressure side always maintains a reference pressure. The maximum displacement of the sensing diaphragm is 0.004 inches (0.10 mm). The displacement is proportional to the pressure. The two capacitance fixed plates of the measuring diaphragm are linearly converted into a 2-wire current, voltage or digital HART output signal of 4-20mADC by the amplifying circuit.

What is a diaphragm seal?

Diaphragm seals, also known as chemical seals or remote seals, are used for pressure measurements when the process medium should not come into contact with the pressurised parts of the measuring instrument.

A diaphragm seal has two primary tasks:

- Separation of the measuring instrument from the process medium

- Transfer of the pressure to the measuring instrument

Extended reading: SI-703 Flush Diaphragm Pressure Sensor

What is remote seal?

The remote seal is used to prevent the medium in the pipeline from directly entering the pressure sensor assembly in the pressure transmitter. It is connected to the transmitter by a capillary filled with fluid. As a result, they’re often used in refining, petrochemical, and chemical plants.

Applicaitons of diaphragm seal

Typical applications where a diaphragm seal provides a cost-effective solution, to protecting the pressure instrument are:

- In applications where the process fluid is corrosive;

- In applications where the process fluid has a high viscosity,

is comprised of slurries, sludge or other material that can actually coat,

or damage a traditional pressure measuring device;

- In applications where the process fluid can freeze or polymerize,

thus causing a condition that might lead to the instrument becoming immobilized,

or incapable of transmitting an accurate pressure measurement or signal.

The process side of the seal is isolated by a flexible diaphragm. The internal space between this diaphragm and pressure measuring sensor is filled with a system fill fluid. The pressure is transmitted from the measured medium, by the elastic diaphragm into the fluid. And from there to the measuring element, i.e. to the pressure measuring instrument or the transmitter.

Often, between the diaphragm seal and pressure measuring instrument, a capillary is connected. Capillary can eliminate or to minimize temperature effects from the hot fluid to the measuring instrument.

A Remote seal is mounted to the process by threaded, flanged, in-line, sanitary, or other connections. Usually, the fittings consist of T-pieces which are integrated into a pipeline, or of welding sockets which are welded to a pipeline, the process reactor or a tank.

This diaphragm seal type offers the advantage, that the “contact surface” between pressure medium and the diaphragm is relatively large. Thus ensuring accurate pressure measurement, especially for very low pressures (< 600 mbar).

Although standard remote seal bodies and diaphragms, are made of stainless steel, a variety of materials, from carbon steel to Hastelloy® C-276, are available to meet the demand of most applications.

A remote seal from Sino-Instrument can operate in pressure applications from 10″ Hg to 20,000 psi, and media temperatures between -130°F and 752°F. We can try to Learn more about the functionality, areas of application and advantages of a diaphragm seal in the following WIKA video.

Extended reading: Flat Pressure Sensor for High Viscosity Fluids

Diaphragm type pressure transmitter

Data sheet of SMT3151 Diaphragm Seal Pressure transmitters

Diaphragm seal pressure transmitter installation

- The remote pressure transmitter without capillary can be directly installed through the remote flange. The position deviation will produce a correctable zero offset

- The electronic watch case can rotate 360 degrees at the maximum. The positioning screw can fix it at any position.

- Single-crystal silicon remote flange is connected with the matching flange conforming to ANSI / DIN standard. The matching flange should be equipped with soft gasket and fixed bolts and nuts. The user can choose to install bolts and nuts.

- For the remote transmission pressure transmitter with capillary, if the remote transmission sealing device is lower than the transmitter body, the maximum height drop between the remote transmission sealing device and the transmitter body should be less than 5m. When the working pressure is lower than 100kPa absolute pressure, the transmitter body must be lower than the remote transmission sealing device.

- The minimum bending radius of the capillary is 75mm, winding is strictly prohibited

Q&A

Parameters that determine the design of a remote seal transmitter

Location of the transmitter (indoor versus outdoor).

Temperatures (process and ambient).

Exposure to vacuum.

Pressure (operating and maximum).

Length of capillary.

Type of seal desired.

Process connection, material of construction and similar considerations.

Installation requirements.

Measurement span.

When are threaded connections used with diaphragm seals?

The combinations of diaphragm seals with threaded connection can be used for processes with extreme temperatures and with aggressive, adhesive, corrosive, environmentally hazardous or toxic media.

Why are there different system fill fluids with diaphragm seals?

In selecting the system fill fluid for diaphragm seals, factors such as compatibility (physiologically harmless) and also temperature and pressure conditions at the measurement location are of crucial importance. Depending on the system fill fluid, the appropriate minimum and maximum operating temperature range must be observed.

How are the diaphragm seals connected?

The diaphragm seals are available with female or male thread in their basic design. Due to the wide variety of available process connections they can be mounted to many different connections without any problems. Generally these connections are T-pieces which are integrated into a pipeline or welded to a pipeline by means of a welding socket.

Sino-Instrument offers SMT3151 Diaphragm Seal Pressure transmitter. Work the same as Wika diaphragm seal pressure transmitter; diaphragm seal pressure transmitter Rosemount; Yokogawa diaphragm seal pressure transmitter.

Sino-Instrument are diaphragm seal pressure transmitters manufacturer. We can offer you automated instruments from China, With best price.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.