Ultrasonic level sensor applications are across a wide range of industries, from water and wastewater treatment to the food and beverage industry. And they play a crucial role in ensuring accurate and reliable measurements of liquids and other materials. We’ll dive deep into the world of ultrasonic level sensor applications. Whether you’re a seasoned professional or just starting out, if you have new research or questions about Ultrasonic Level Sensor Applications, please feel free to contact us.

Ultrasonic Level Sensor Applications

Application 1: Liquid Level Monitoring in the Food and Beverage Processing

Ultrasonic Level Sensor, which is non-contact and pollution-free, has been paid more and more attention as an important part of food equipment.

As a liquid level measurement and control instrument—Ultrasonic Level Sensor, it truly protects food. In the beverage industry, strict hygiene testing is a basic requirement for food and beverages.

Ultrasonic Level Sensor can solve the monitoring of beverage storage, including the detection of containers such as wine and fruit juice. The non-contact measurement method ensures a good production environment.

The integrated design of Ultrasonic Level Sensor is convenient for installation and maintenance, and also brings great convenience to the production and monitoring process.

At the same time, with the improvement of living standards, our requirements for food packaging are gradually increasing. Ultrasonic Level Sensor is used to detect whether the packaging box is full, quantify the packaging volume, control the filling liquid level, etc. Improve production efficiency above 50%.

And provide continuous monitoring data for production enterprises. The timely sharing of data has a very positive impact on food accident handling and food risk assessment and judgment.

Today, the issue of food is one of the public issues that the public is still concerned about, and the Ultrasonic Level Sensor application provides a powerful umbrella for the monitoring and management of the beverage and food industries.

Ultrasonic Level Sensor’s diverse installation methods, beam angle design of less than 9°C, and response time of less than 200ms to ensure higher accuracy make Ultrasonic Level Sensor more important in Liquid Level Monitoring in the Food and Beverage Processing.

In addition to Ultrasonic Level Sensor, ultrasonic flow measurement also plays an important role in Food and Beverage Processing.

Application 2: Tank Level Monitoring in the Oil and Gas Industry

The oil and gas industry is all about efficiency, accuracy, and safety, and ultrasonic level sensors play a crucial role in achieving these goals. Ultrasonic Level Sensors are used in a variety of applications, from measuring the level of liquids in tanks to monitoring the flow of liquids in pipelines.

One of the main advantages of using ultrasonic level sensors in the oil and gas industry is their ability to measure liquids with high precision.

Another advantage of ultrasonic level sensors is their non-contact measurement method. Unlike other sensors that come into direct contact with the material being measured, ultrasonic level sensors use sound waves to determine the level, which eliminates the risk of contamination.

Finally, ultrasonic level sensors are also low-maintenance, which is an important factor in the fast-paced and demanding environment of the oil and gas industry.

In conclusion, ultrasonic level sensors are a valuable tool in the oil and gas industry, helping to improve efficiency, accuracy, and safety. With their high precision, non-contact measurement method, and low-maintenance requirements, these sensors are a smart choice for any oil and gas operation.

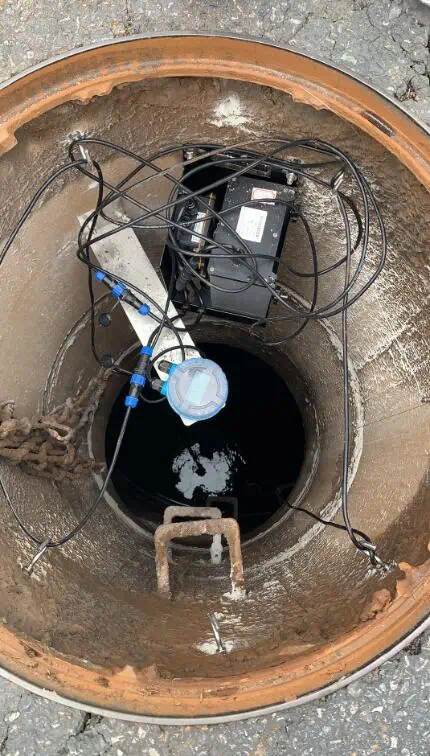

Application 3: Level Measurement in Waste Water Treatment Plants

Ultrasonic Level Sensor is widely used in liquid level measurement projects in waterworks, wastewater treatment plants, chemical reagent factories, dye factories, pulp mills and other factories. It is one of the main liquid level measurement methods in the modern intelligent automation industry.

The composition of sewage is complex and corrosive, and floating objects are easy to form on the surface of the liquid. Therefore, the required Level Sensor is sensitive and reliable. Ultrasonic has the characteristics of strong signal penetration and sensitive response, and is the recommended choice for sewage level measurement.

Judging from the actual application effect of the sewage treatment station, the workers on duty can obtain accurate sewage water level conditions through the LED display. The frequent measurement work of manual ruler inspection is saved. Save a lot of manpower and improve work efficiency.

At the same time, the Ultrasonic Level Sensor can reflect the water level in a timely manner, which is conducive to the real-time and reasonable management and control of the dispatching room according to the water level. It effectively solves the problem of data deviation caused by inaccurate measurement data and ensures the smooth progress of operations.

Read more about:

- Wastewater Level Sensor for Septic Tank-Sewage Holding Tank

- Water Level Monitoring Sensor/System for Sewage-Wastewater

Application 4: Level Measurement in Silos and Hoppers

Application 4: Level Measurement in Silos and Hoppers

The silo material level ultrasonic sensor is used to display the height of the material in the silo (full warehouse, empty warehouse or a certain height material level).

Some people understand that as long as it is a solid, it can be measured, but it is wrong. It has prerequisites for its measurement.

What material levels can Ultrasonic Level Sensor measure?

- Powdery solid: It is difficult to measure it with a general ultrasonic level gauge. Take the measurement of flour as an example, the Ultrasonic Level Sensor with a range of 10 meters can only measure a distance of about 2 meters, and it will not be able to measure it any further. Substances such as cement powder, soybean powder, wood residue, and fly ash are not easy to measure. The powder solids that can be measured include: yellow sand, iron powder, stone powder and other substances with a density greater than 3000 kg/m3.

- Granular solids: the particle diameter is greater than 3mm, and the density is greater than 1000 kg/m3. For example: ABS particles, stones, wheat, etc. Under the premise of no dust, the selected Ultrasonic Level Sensor should be 3 times larger than the actual measuring range.

- Blocky solids: such as: coal, ore, etc., most of the blocky solids can be measured, and the selected Level Sensor range should be 3 times larger than the actual range.

Application 5: Level Measurement in Reservoirs

Reservoirs play a very important role in water conservancy projects. The construction of reservoirs is a hydraulic engineering building for flood storage and regulation of water flow. It can be used for water storage, irrigation, power generation, flood control and fish farming.

Ultrasonic level gauges can measure changes in content in rivers, lakes, seawater, reservoirs, canals, and pools.

The level of liquids in reservoirs is an important indicator of the amount of resources available, and it is used to optimize the production process and minimize waste.

Ultrasonic Level Sensors use sound waves to determine the level of liquids, providing accurate measurements even in challenging environments where traditional sensors may fail.

In conclusion, With their non-contact measurement method, accuracy, and low-maintenance requirements, ultrasonic level sensors are a smart choice for any industry that relies on accurate level measurements in reservoirs.

Read more about: Common River Water Level Measurement Methods

Featured Ultrasonic Level Sensors

Advantages of Ultrasonic Level Sensors

Ultrasonic level sensors are a powerful tool for measuring the level of liquids and other materials, offering several key advantages, including:

- Accurate and Reliable Measurement: Ultrasonic level sensors use advanced technology to determine the level of liquids with high precision, ensuring accurate and reliable measurements.

- Non-Contact Measurement: Ultrasonic level sensors use sound waves to determine the level of liquids, eliminating the risk of contamination through direct contact with the material.

- Immunity to Dust, Vapors, and Liquids: Ultrasonic level sensors are immune to dust, vapors, and liquids, making them ideal for use in challenging environments.

- No Maintenance Required: Ultrasonic level sensors require very little maintenance, making them a low-maintenance solution for accurate level measurements.

Challenges and Limitations of Ultrasonic Level Sensors

While ultrasonic level sensors offer many advantages, they also have some limitations, including:

- Difficulties in Measuring Viscous Liquids: Ultrasonic level sensors can have difficulty measuring viscous liquids accurately.

- Interference from Other Ultrasonic Sources: Ultrasonic level sensors are sensitive to ultrasonic noise, and other ultrasonic sources in the environment can interfere with their accuracy.

- Limited Measurement Range: Ultrasonic level sensors have a limited measurement range, which can be a challenge in certain applications.

- Requires Clear Line-of-Sight to the Surface of the Liquid: Ultrasonic level sensors require a clear line-of-sight to the surface of the liquid in order to obtain accurate measurements.

Frequently

Asked

Questions

More Ultrasonic Level Applications and Markets

Ultrasonic Depth Sensor vs Ultrasonic Level Sensor

How to Choose Explosion Proof Ultrasonic Level Sensor?

New Choice for Heating Oil Tank Level Sensor

What Is Capacitive Level Sensor?

How to Choose the Right Diesel Fuel Level Sensor ?

Submersible Level Transducer – First Choice for Water Level

Conclusion

Ultrasonic Level Sensor Applications are far more than the 5 mentioned in this article. There are many special applications that we have not mentioned.

Ultrasonic level sensors are a powerful tool for level measurement, providing reliable and accurate measurements for many industries. Whether you’re looking for a solution for level measurement in reservoirs, or any other application, ultrasonic level sensors are a valuable and versatile.

As Ultrasonic Level Sensors manufacturer and supplier, we supply more than 20 kinds of Ultrasonic Level Sensors.

If you have special requirements for Ultrasonic Level Sensor Applications, or have related technical questions. Feel free to contact us any time.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.