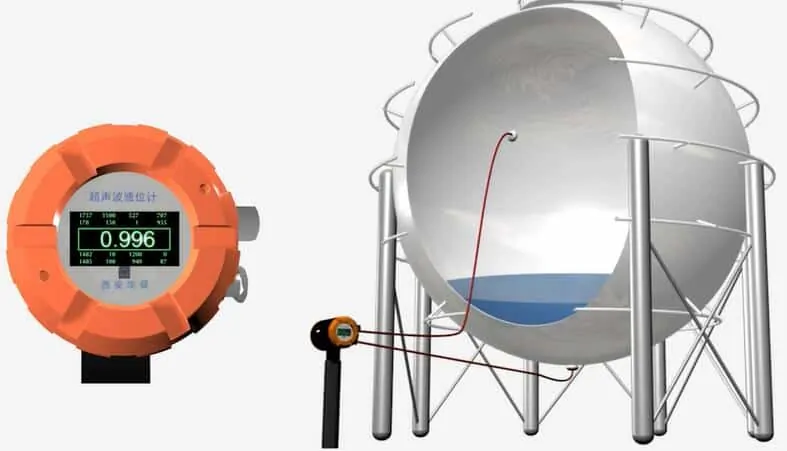

Ultrasonic sensor for water level measurement

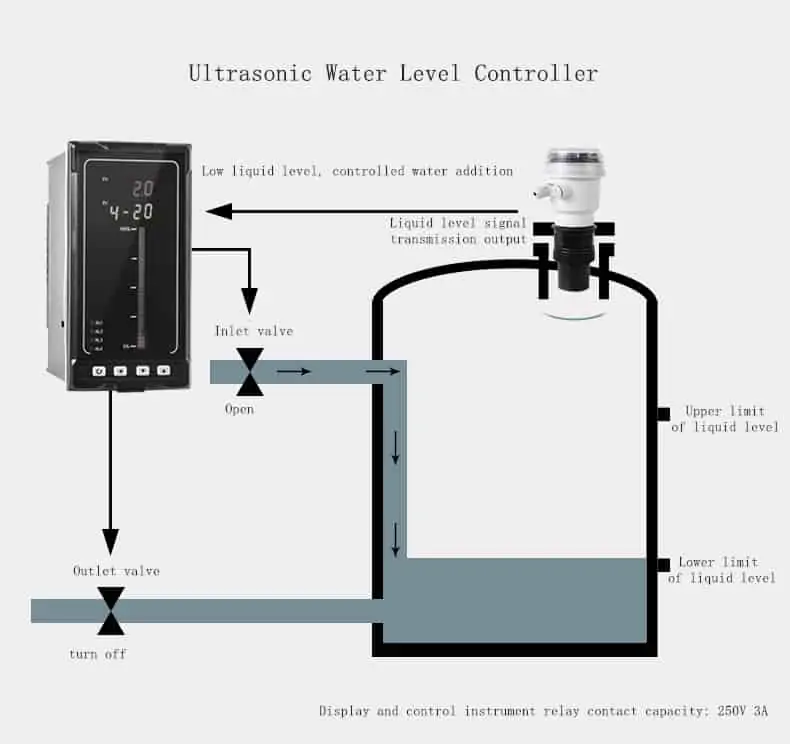

Ultrasonic Water Level Sensor refers to the ultrasonic level sensor used to measure the water level. Used for industrial liquid tanks, or river water level non-contact monitoring and control.

Ultrasonic Water Level Sensor is also often called “Ultrasonic Level Sensor”, “Ultrasonic Level Detector”, “Ultrasonic Level Sensor 4-20ma” or “Ultrasonic Level Transmitter” “Ultrasonic liquid level sensor”

Sino-Inst offers a variety of Ultrasonic Water Level Sensors for level measurement. If you have any questions, please contact our sales engineers.

Featured Ultrasonic Water Level Sensors

| Model | High-precision with small blind area | Universal ultrasonic level meter | Explosion-proof | Split type |

|  |  |  | |

| Range | 1m, 2m | 5-60 m | 0-15 m (large range can be customized); | 5 -70 meters |

| Blind area | <0.06-0.15m | <0.4-1.5m | 0.35 m~0.5 m | 0.25m~0.6m |

| Accuracy | <±1mm | ±0.25%F.S | ±0.5%F.S | 0.5%-1.0% |

| Output | 4-20mA, RS485Switch output: three NPN | 4-20mA, 4-20mA+HART, RS485 Switch output: NPN/relay | Analog output: 4~20 mA (optional 1-2 relay output); digital output: RS485(modbus) protocol; | Analog output: 2 4~20mA/5100 loads Relay output: 2 groups of AC250V/8A or DC30V/5A state programmable (optional) |

| Power supply | 24VDC | 24VDC, 220VAC | DC12V, DC24V/AC220V | 220VAC+15%50Hz or 24VDC120mA |

| Installation | M30×1.5 or G11/2 | M60×2 | M60×2 | according to range and probe selection |

Ultrasonic Level Measurement Applications

- The flexible design of the ultrasonic liquid level sensor can be applied to integrated systems or replace float switches, conductivity switches and static pressure sensors;

- It is suitable for the comprehensive application of fluid control and chemical supply system;

- Widely used in various atmospheric storage tanks, process tanks, small tanks and small containers, pump lifting stations, waste water storage tanks.

Extended reading: Capacitive water level sensor

Sewage level measurement

The composition of sewage is complex and corrosive, and floating objects are easily formed on the surface of the liquid level. Therefore, the level gauge needs to be sensitive and reliable.

Ultrasonic signal has strong penetrating power and sensitive response, which is a reliable helper for your liquid level measurement.

Clean water level measurement

The demand for water level measurement of rivers and lakes and road area is very common.

The liquid level data must not only be reliable, but also be able to upload the data online to facilitate real-time monitoring.

Ultrasound can be equipped with 485 function, which will effectively meet your needs.

Corrosive level measurement

In acid-base level measurement, not only the liquid is corroded, but also the chemical reaction will generate heat, which will interfere with the level measurement.

Ultrasonic can be customized for anti-corrosion, helping you to reliably realize automatic dosing ratio.

Particle level measurement

Particle level measurement is easy to produce false signals, which requires the level gauge to filter clutter.

The ultrasonic level gauge has an intelligent algorithm to automatically remove false echoes, and is used for level measurement of tanks and other materials. It is accurate and reliable!

Ultrasonic water level sensor working principle

The working principle of the ultrasonic liquid level sensor is:

Ultrasonic transducer (probe) emits high-frequency pulse sound waves, and the surface of the measured level (material) is reflected back. The reflected echo is received by the transducer and converted into an electrical signal. The propagation time of the sound wave is proportional to the distance from the sound wave to the surface of the object.

The relationship between the sound wave transmission distance S and the sound speed C and the sound transmission time T can be expressed by the formula: S=C×T/2.

The probe part emits ultrasonic waves, which are then reflected by the liquid surface. The probe part is received again. The distance from the probe to the liquid (object) surface is proportional to the elapsed time of the ultrasonic wave:

hb = CT2

Distance [m] = time × speed of sound/2 [m]

The temperature compensation formula of sound velocity:

Ambient sound velocity = 331.5 + 0.6 × temperature

Extended reading: The Secret of Ultrasonic Level Measurement

Ultrasonic Level Sensor Advantages and Disadvantages

The Advantages of ultrasonic liquid level gauge are very outstanding. It is mainly reflected in the following aspects:

- The structure is simple. The reading is convenient. It is very easy to install and maintain.

- Safe and clean. The instrument has long service life. The measurement is stable and reliable with high precision.

- Adopt non-contact measurement. It is not easily affected by the viscosity and density of the liquid.

- Simple installation and operation

- No moving parts

- Continuous water level detection

- Can be used some non-liquid materials/media

- High accuracy & sensitivity

Of course, the ultrasonic liquid level gauge also has its own limitations and insurmountable defects. Specifically, Disadvantages is mainly manifested in:

- There is a blind spot in ultrasonic liquid level sensor measurement.

- Ultrasonic liquid level sensor measurement is easily affected by temperature.

- There should be no obstacles under the ultrasonic liquid level sensor.

- Ultrasonic liquid level sensor should not be used to measure pressure vessels.

- The ultrasonic liquid level sensor cannot be used in occasions where there is water mist, a large amount of foaming medium, and a volatile medium.

- Ultrasonic liquid level sensor is greatly affected by dust.

Can ultrasonic sensor detect water level?

Yes. Ultrasonic sensors can be used for water level measurement. And, most of the time, ultrasonic water level sensor is a common choice for water level measurement sensors.

How does ultrasonic water level sensor work?

The ultrasonic level sensor adopts the ultrasonic pulse echo method to achieve liquid level measurement. Specifically, the transducer (probe) of the ultrasonic level gauge emits high-frequency ultrasonic pulses. When it encounters the surface of the liquid level to be measured, the sound wave is reflected back, and part of the reflected echo is received by the transducer (probe) and converted into With electrical signals, users can know the water level almost in real time based on the reflected signals.

Which sensor is used in water level indicator?

There are 7 main types of level transmitters that Sino-Inst offers for water level indicate. Each type of transmitter works in a different way, and makes it useful for different types of processes.

Read more about: 7 Level Senors for Tank Level Measurement

Related products

The specific ultrasonic water level sensor price needs to be selected and quoted according to your measurement parameters. Please contact Sino-Inst sales engineer!

Extended reading: Magnetostrictive Hydraulic Cylinder Position Sensor

Extended reading: Water Tank Level Controller

Sino-Inst is a manufacturer of Ultrasonic Water Level Sensors.

Sino-Inst offers over 20 Ultrasonic Water Level Sensors at best price. About 50% of these are Pressure level Transducer, 40% are Differential Pressure transmitters, and 40% are Ultrasonic Water Level transmitters.

A wide variety of Ultrasonic Water Level Sensors options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Ultrasonic Water Level Sensors, located in China. Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide. Ultrasonic Water Level Sensors products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.