What is a HART Pressure Transmitter?

The HART Pressure Transmitter is a two-wire intelligent pressure measurement instrument based on the HART protocol, suitable for precision fluid pressure measurement. The intelligent HART Pressure Transmitter retains a 4~20mA current loop signal while transmitting digital signals. Using a HART handheld device or a smart instrument with HART functionality, users can communicate with the pressure transmitter to perform parameter settings, read diagnostic information, and other operations.

Sino-Inst offers a variety of HART pressure transmitters for industrial pressure measurement. If you have any questions, please contact our sales engineers.

What is hART in a pressure transmitter?

The HART protocol is a backward-compatible smart instrument solution for the transition from analog to digital systems.

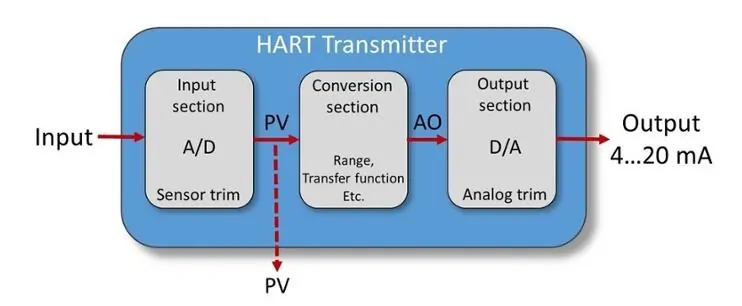

A typical HART smart instrument generally consists of a power supply module, sensor interface circuitry, A/D conversion circuitry, MCU, D/A output circuitry, and HART communication circuitry.

HART (Highway Addressable Remote Transducer) is a communication protocol introduced by Rosemount Corporation in 1985 for communication between field smart instruments and control room equipment.

Traditional pressure transmitters only provide a 4-20mA current loop output analog signal. HART smart pressure transmitters retain the 4-20mA current loop signal while transmitting digital signals, playing a crucial role in the transition from analog to digital instruments.

The HART protocol uses FSK frequency shift keying signals based on the Bell202 standard, superimposing a 0.5mA audio digital signal onto a low-frequency 4-20mA analog signal for bidirectional digital communication, with a data transmission rate of 1.2kbps. Since the average value of the FSK signal is 0, it does not affect the magnitude of the analog signal transmitted to the control system, ensuring compatibility with existing analog systems.

In HART protocol communication, the main variables and control information are transmitted via 4-20mA. Additional measurement, process parameters, equipment configuration, calibration, and diagnostic information can be accessed via the HART protocol when needed.

Benefits of HART pressure transmitters

- 4~20mA DC current output superimposed HART® protocol digital communication (two-wire system);

- Adopt digital compensation and nonlinear correction technology;

- -10℃~80℃ digital wide temperature compensation;

- With local and remote zero and span adjustment functions;

- Key operation on site for easy configuration.

- Shorten troubleshooting time from discovery to problem solving;

- Continuously verify the integrity of loops and control/automation system strategies;

- Improve asset efficiency and system availability;

- Quickly determine and verify control loops and device configurations;

- Use remote diagnosis to reduce unnecessary on-site inspections.

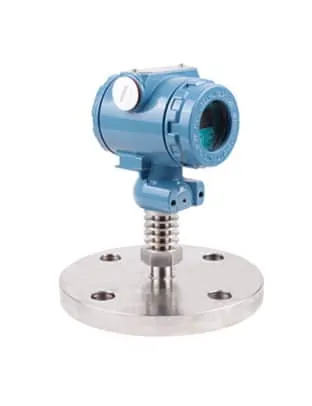

Featured Industrial HART Pressure Transmitters

HART pressure transmitter is a complete product line of liquid level, differential pressure, gauge pressure and absolute pressure transmitters. Models include flushing diaphragms and sanitary flanges for liquid level measurement, hydrostatic tank metering – HTG. And wetted parts of various materials to suit the process requirements.

You may like: Verabar Flow Meter

How to calibrate a pressure transmitter using HART?

A pressure transmitter is one of the most common instruments in a process plant. To assure its accuracy, it needs to be calibrated.

But what do you need to calibrate it and how is it done?

You may know how to calibrate a pressure transmitter? Or, how to calibrate a differential pressure transmitter? Then, calibrate HART pressure transmitters, kind of like pressure transmitter calibration using a hart communicator. Pressure transmitter manufacturers have improved accuracy and technology, designed into these smart pressure measurement devices.

To calibrate a pressure transmitter, you need:

loop supply (if not connected to the controls system’s loop supply);

a pressure generator to generate input pressure;

an accurate calibrator to measure the input pressure;

an accurate calibrator to measure the output mA current.

Typically, the pressure transmitter is a HART protocol transmitter. So in case, there is any need to adjust/trim it, you will need to use a device supporting HART communication.

How to calibrate HART pressure transmitters?

Explaining how to do the calibration would result in quite a long text. So we have put together a video for you instead. The video shows you how to calibrate and trim a HART pressure transmitter. Please have a look at the video: How to calibrate HART pressure transmitters

Video source: https://www.youtube.com/watch?v=4wLCqH0M9fU&t=9s

HART Pressure Transmitters Calibration Steps

How to calibrate HART pressure transmitters?

Total Time: 20 minutes

1. Isolate the transmitter from the process being measured and its loop wiring.

2. If measuring the mA signal across the transmitter test diode leave the wires intact, but note this method does not give the best mA measurement accuracy.

3. Connect the mA measurement jacks of the 754 to the transmitter.

4. Connect the pressure module cable to the 475, and connect the transmitter test hose from the hand pump to the transmitter.

Press the HART button on the calibrator to see the configuration of the transmitter.

5. Press HART again and the calibrator will offer the correct measure/source combination for the test.

6. If documenting the calibration press As-Found, input the test tolerance and follow the prompts.

7. If the measured mA signal at the test points is found within tolerance the test is complete.

If not, change is required.

Select, adjust, and trim the pressure zero, mA output signal and input sensor.

If you still do not know how to check the pressure transmitter? Or, how to calibrate a pressure transmitter. Just contact us.

More Pressure Measurement Solutions

- High Frequency Dynamic Pressure Sensor

- Intrinsically Safe vs Explosion Proof Pressure Transmitters

- How to Calibrate a Pressure Transmitter

- Differential Pressure Transmitter Installation Guide

- Use Differential Pressure Transmitter to Measure Liquid Level

- MEMS Pressure Sensors

- Application Analysis of Intelligent Pressure Transmitter

- Differential Pressure Flow Meters

- Water Pressure Transducers

- Capacitive pressure transducer

- Pressure indicator transmitters

- How Does a Pressure Transmitter Work?

- Pressure Transmitter Calibration

Sino-Inst offers over 20 SMART HART Pressure Transmitters. About 50% of these are 4-20ma Low-Pressure Transducers, 40% are Differential Pressure Gauge, and 20% are Diaphragm Seal Pressure transmitters, 20% are 4-20ma differential pressure transmitters.

Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide. HART Pressure Transmitter products are most popular in the domestic market, Southeast Asia, and Mid East. You can ensure product safety by selecting from certified suppliers with ISO9001, ISO14001 certifications.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.